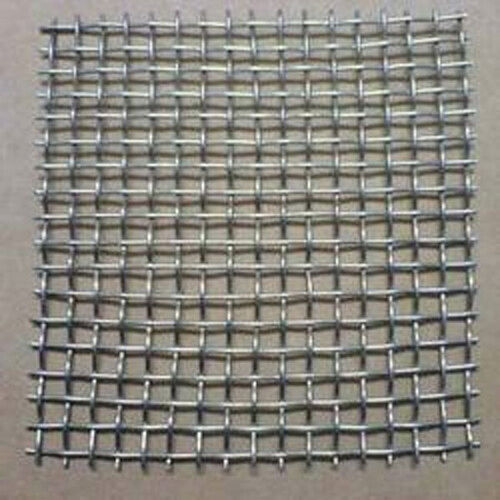

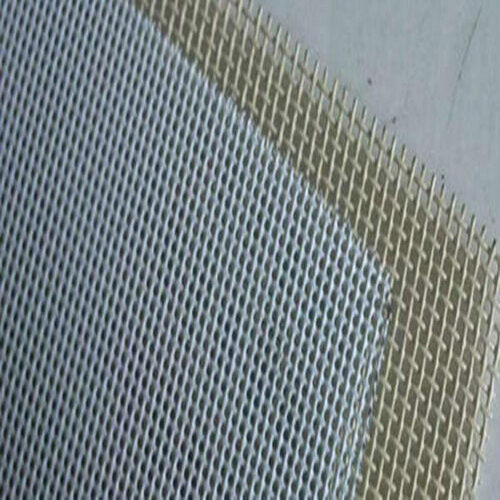

314 Stainless Steel Welded Wire Mesh

Price 50 INR/ Unit

314 Stainless Steel Welded Wire Mesh Specification

- Hole Shape

- Square

- Wire Gauge

- 14 - 22 gauge

- Length

- 30 meters

- Aperture

- 1/8 inch to 2 inch

- Surface Treatment

- Coated

- Product Type

- Wire Mesh

- Mesh Type

- Welded

- Mesh Style

- Welded Mesh

- Material

- Stainless Steel

- Alloy

- 314 Stainless Steel

- Application

- Other

- Dimensions

- Custom sizes available

- Wire Diameter

- 0.5 mm - 2 mm

- Weight

- Varies as per dimensions

- Color

- Gray

- Edge Type

- Plain / Cut edge

- Packing Type

- Rolls / Panels

- Standard

- ASTM A580

- Tensile Strength

- 850 MPa

- Usage

- Filtration, Fencing, Sieving, Construction

- Corrosion Resistance

- High

- Temperature Tolerance

- Up to 1100°C

314 Stainless Steel Welded Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About 314 Stainless Steel Welded Wire Mesh

314 Stainless Steel Welded Wire Meshis easy to work with and is available in different hole sizes, thickness and other configurations in order to meet your specific application requirements. We offer an exclusive range of 314 Stainless Steel Welded Wire Mesh at unmatched quality and market leading prices.

These high-quality products are manufactured at our premises using quality tested raw materials and components according to industry quality standards.Indo German Wire Screen Co., we are the professional people delivering high-quality and superior-performance products that have been appreciated by all of our previous customers.Indo German Wire Screen Co. manufacturing and exporting high quality 314 Stainless Steel Welded Wire Mesh worldwide.

Built for High Demands

With its robust 314 stainless steel alloy and coated welding, this mesh is ideal for corrosive, high-temperature environments. Rigorously meeting ASTM A580 standards, it performs reliably in filtration, fencing, and sieving.

Versatile Configuration Options

Available in varied gauges, apertures, and custom dimensions, 314 stainless steel welded wire mesh adapts seamlessly to project-specific requirements. Both rolls and panels are offered, with edge types tailored for installation needs.

Applications Across Industries

Used extensively in construction, industrial filtration, safety fencing, and material sieving, this mesh stands out for its longevity and resilience. Its resistance to rust and heat ensures optimal function even under tough conditions.

FAQs of 314 Stainless Steel Welded Wire Mesh:

Q: How is 314 stainless steel welded wire mesh manufactured?

A: This mesh is produced by welding intersecting wires of 314 stainless steel, ensuring strong joints and structural integrity. The surface is then coated for added corrosion protection, conforming to ASTM A580 standards.Q: What benefits does 314 stainless steel provide in welded wire mesh?

A: 314 stainless steel exhibits superior resistance to corrosion and oxidation, particularly at elevated temperatures up to 1100C. This translates into a mesh that is durable, low-maintenance, and well suited to harsh environments.Q: Where can I use 314 stainless steel welded wire mesh?

A: This mesh is ideal for applications including filtration, fencing, sieving, and construction. Its versatility, temperature resistance, and strength make it suitable for both industrial and architectural settings.Q: What are the available mesh sizes and configurations?

A: 314 stainless steel welded wire mesh is available in wire gauges from 14 to 22, with apertures ranging from 1/8 inch to 2 inches and wire diameters between 0.5 mm and 2 mm. Custom dimensions and various hole shapes, such as square or other configurations, can be supplied.Q: When should I consider using coated welded mesh over uncoated mesh?

A: Coated welded mesh provides enhanced resistance to corrosion, especially in environments exposed to moisture, chemicals, or salt. If your application involves such conditions or requires extended service life, coated mesh is recommended.Q: What packing types are offered for this welded mesh?

A: The mesh is supplied in either rolls or panels, depending on your specific requirements. Both options allow for efficient handling, transportation, and installation in construction or industrial settings.Q: How does the tensile strength of 314 stainless steel mesh benefit my project?

A: With a tensile strength of 850 MPa, this welded mesh offers excellent load-bearing capacity and structural support. This makes it a reliable choice for safety fencing, heavy-duty sieving, and reinforcement in construction projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Welded Wire Mesh Category

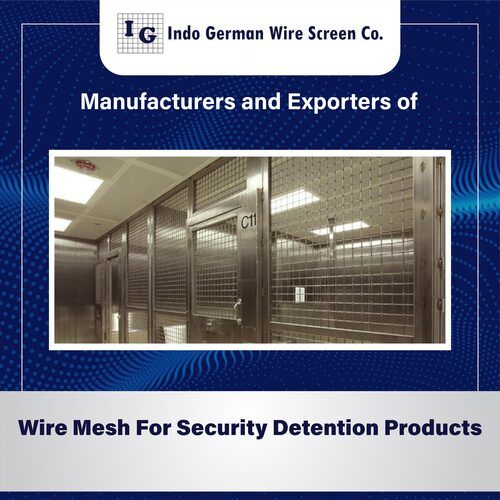

Wire Mesh For Security and Detention Products

Price Range 400.00 - 1000.00 INR / Foot

Minimum Order Quantity : 50 Feet, ,

Application : Other, Security fencing, detention centers, prison enclosures, industrial safety

Product Type : Wire Mesh

Mesh Style : Other , Welded or Woven

316 L Stainless Steel Welded Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other

Product Type : Wire Mesh

Mesh Style : Welded Mesh

304 L Stainless Steel Welded Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other

Product Type : Wire Mesh

Mesh Style : Welded Mesh

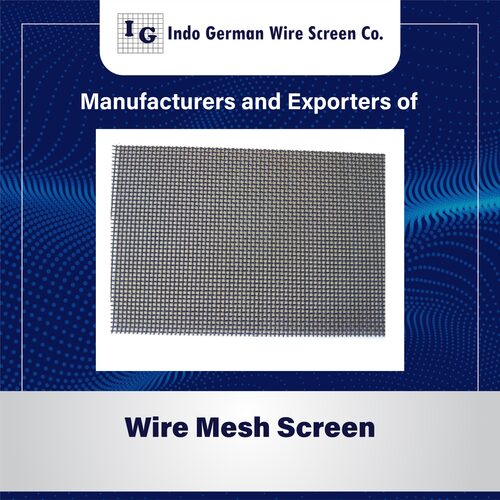

Wire Mesh Screen

Price Range 400.00 - 1000.00 INR / Foot

Minimum Order Quantity : 50 Feet

Application : Screen

Product Type : Wire Mesh

Mesh Style : Welded Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry