321 Stainless Steel Wire Mesh

Price 120 INR/ Square Foot

MOQ : 10 Square Meters

321 Stainless Steel Wire Mesh Specification

- Hole Shape

- Square Hole

- Product Type

- Wire Mesh

- Mesh Type

- Steel Wire Mesh

- Mesh Style

- Other

- Material

- Steel

- Color

- Sliver

321 Stainless Steel Wire Mesh Trade Information

- Minimum Order Quantity

- 10 Square Meters

- Supply Ability

- 10 Square Meters Per Day

- Delivery Time

- 1 Week

About 321 Stainless Steel Wire Mesh

Product Details:

| Material | SS321 |

| Mesh Size(per inch) | 0-10 per inch |

| Weave Type | PSW |

| Surface Finish Coating | Black Powder |

USN S32100321 SS is a heat resistant steel containing titanium to form a carbide of low solid solubility for a reduced possibility of inter granular precipitation and of associated inter granular corrosion. 321 SS exhibits a high degree of resistance to corrosion and oxidation while possessing high creep strength. Type 321 is primarily used for welded construction and for parts intermittently heated within 900-1600F. 321 SS is nonmagnetic when annealed, and slightly magnetic when cold worked.

Composition [Cr 17-19%, Ni 9-12%, Ti 5xC min., C 0.08 max.]

Specifications ASTM A580, AMS 5689

Exceptional Durability and Performance

Engineered from 321 stainless steel, this wire mesh delivers excellent resistance against corrosion and oxidation. The addition of titanium enhances its stability even at elevated temperatures, making it suitable for demanding industrial applications. Its square hole design offers precision and versatility for multiple filtration, screening, and reinforcement tasks.

Wide Range of Industrial Uses

Due to its robust construction and non-reactive surface, 321 Stainless Steel Wire Mesh is widely used in industries such as chemicals, food processing, and automotive. It serves effectively in filtration, sifting, and safety guarding. Its adaptability ensures it meets specific requirements across different sectors.

Reliable Supply from India

India hosts a large network of exporters, manufacturers, suppliers, and traders specializing in 321 stainless steel wire mesh. These professionals adhere to strict quality standards, ensuring that customers receive mesh products that meet international specifications and demand.

FAQs of 321 Stainless Steel Wire Mesh:

Q: How is 321 Stainless Steel Wire Mesh manufactured?

A: 321 Stainless Steel Wire Mesh is produced using high-grade steel alloyed with titanium, which is drawn into wires and then woven or welded into a mesh with square holes. The process ensures consistent hole size and superior structural integrity.Q: What are the primary uses of 321 Stainless Steel Wire Mesh?

A: This mesh is primarily used for filtration, sifting, and screening in industries like chemical processing, food production, and automotive manufacturing due to its strength and resistance to corrosion.Q: When should I select 321 grade over other stainless steel meshes?

A: Opt for 321 Stainless Steel Wire Mesh when you require resistance to oxidation at high temperatures, particularly in applications where thermal stability and durability are vital.Q: Where can I purchase 321 Stainless Steel Wire Mesh in India?

A: You can purchase this wire mesh from various exporters, manufacturers, suppliers, and traders located across India, many of whom can offer custom sizes and specifications to meet your projects needs.Q: What is the process of installing steel wire mesh with square holes?

A: Installation involves cutting the mesh to desired dimensions, securing it within a frame or structure, and fastening it using clips, welding, or bolts depending on the intended application and load-bearing requirements.Q: How does the square hole design benefit the meshs performance?

A: The uniform square hole shape enhances accuracy in filtration and screening, allowing for consistent flow and separation of materials while maintaining overall mesh strength.Q: What are the key benefits of using 321 Stainless Steel Wire Mesh?

A: Key benefits include its exceptional resistance to corrosion, high-temperature tolerance, structural strength, and suitability for a wide range of industrial applications, ensuring a long operational life.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Wire Mesh Category

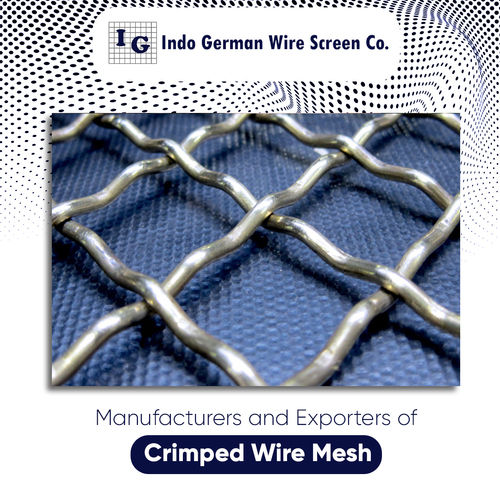

Crimped Wire Mesh

Price Range 150.00 - 190.00 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Mesh Type : Steel Wire Mesh

Color : Silver

Product Type : Wire Mesh

Wire Cloth

Price Range 40.00 - 400.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Mesh Type : Steel Wire Mesh

Color : Silver

Product Type : Wire Cloth

Spring Steel Wire Mesh

Price 130 INR

Minimum Order Quantity : 10 Square Foots

Mesh Type : Steel Wire Mesh

Color : Silver

Product Type : Wire Mesh

Wire Screens

Price Range 35.00 - 125.00 INR / Square Foot

Minimum Order Quantity : 10 Square Meters

Mesh Type : Steel Wire Mesh

Color : Silver

Product Type : Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry