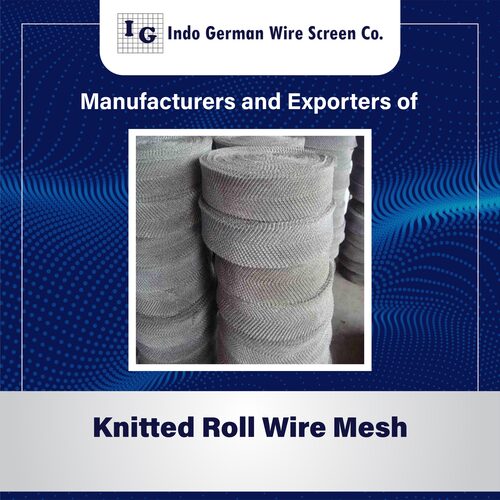

Knitted Roll Wire Mesh

Price 120 INR/ Square Meter

MOQ : 10 Square Meters

Knitted Roll Wire Mesh Specification

- Wire Gauge

- Customizable as per requirement

- Surface Treatment

- Galvanized or Plain Stainless Steel

- Length

- Standard rolls of 10 m, 15 m, 30 m or as per requirement

- Aperture

- 1 mm to 10 mm (Standard); Custom sizes available

- Hole Shape

- Rectangular

- Product Type

- Wire Mesh

- Mesh Type

- Steel Wire Mesh

- Mesh Style

- Knitted

- Material

- Stainless Steel

- Alloy

- SS304, SS316 or as specified

- Application

- Filtration, Demister Pads, Air and Liquid Filtration, Oil Mist Collection, EMI Shielding, and Gasket Applications

- Dimensions

- Width: 100 mm to 660 mm (Roll Form as per order)

- Wire Diameter

- 0.08 mm to 0.30 mm

- Weight

- 250 g/m to 1,000 g/m based on mesh specifications

- Color

- Sliver

Knitted Roll Wire Mesh Trade Information

- Minimum Order Quantity

- 10 Square Meters

- Supply Ability

- 10 Square Meters Per Day

- Delivery Time

- 1 Week

About Knitted Roll Wire Mesh

Product Details:

| Size | 0.10 mm- 0.70 mm |

| Material Grade | SS 304, 316 |

| Material | MS, SS, GI, Aluminiuim |

| Type | Woven |

| Weaven Type | Knitted Mesh |

Since our inception, we are engaged in offering our clients with Knitted Roll Wire Mesh that is widely demanded by various industries and sectors. They are extensively used in laboratories, pilot plants and also for commercial purposes. Patrons widely appreciate our offered Knitted Wire Mesh Rolls as these have longer service life, resistance against corrosion and flawlessness. Our offered wire mesh is available in several specifications in accordance with the customer s needs.

Features:

- Low value of HTEP

- High vapor handling capacity

- High mass transfer capacity

- Provides large surface for desired inter phase mixing

Exceptional Durability and Versatility

This wire mesh offers superior resilience in harsh environments due to its stainless steel construction and excellent corrosion and temperature resistance. Customizable specifications enable it to suit a variety of technical requirements across diverse industries, including filtration, shielding, and sealing.

Precision Engineering for Specialized Applications

Knitted Roll Wire Mesh is designed for precision performance in tasks like air and liquid filtration or EMI shielding. Its flexible form and customizable apertures support seamless integration in advanced equipment, ensuring reliable results and long service life.

FAQs of Knitted Roll Wire Mesh:

Q: How is Knitted Roll Wire Mesh typically used in industrial applications?

A: Knitted Roll Wire Mesh is widely used for filtration, demister pads, EMI shielding, oil mist collection, and gasket manufacturing, particularly in facilities where corrosion resistance and temperature stability are necessary.Q: What customization options are available for this mesh product?

A: Customers can specify wire gauge, mesh dimensions, roll length, aperture size, edge finish, and select from alloys like SS304 or SS316 and surface treatments such as galvanized or plain stainless steel.Q: What is the process of ordering and receiving Knitted Roll Wire Mesh?

A: Clients can place orders with a minimum quantity of 10 rolls; rolls or cut-to-size sheets are packed in moisture-proof packaging and dispatched from India by exporter, manufacturer, supplier, or trader as per specification.Q: Where can Knitted Roll Wire Mesh be installed or applied?

A: It can be utilized in industrial equipment, automotive components, marine structures, construction projects, and electronic assemblies for shielding and filtration purposes.Q: What benefits does knitted wire mesh offer compared to other mesh types?

A: Knitted wire mesh provides increased flexibility, effective particulate capture, superior durability under high temperatures, and excellent resistance to corrosive environments, making it suitable for advanced technical applications.Q: When is reinforced edge finish recommended for this mesh?

A: Reinforced edge finish is advisable when the wire mesh undergoes mechanical stress or needs robust installation, ensuring structural integrity and longevity during operation.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Wire Mesh Category

Monel Wire Mesh

Price Range 450.00 - 1500.00 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Product Type : Wire Mesh

Mesh Type : Steel Wire Mesh

Color : Silver

SS Wire Mesh For Hydraulic Filters

Price 1000-100000.00 INR / Foot

Minimum Order Quantity : 50 Feet

Product Type : Wire Mesh

Mesh Type : Steel Wire Mesh

Color : Black

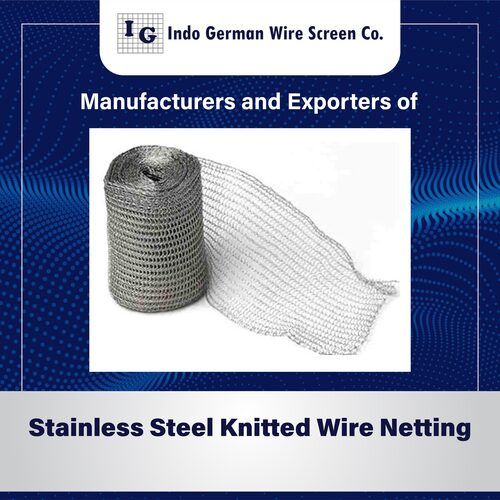

SS Knitted Wire Mesh

Price 14 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Product Type : Wire Mesh

Mesh Type : Steel Wire Mesh

Color : Silver

Twill Dutch Weave Wire Mesh

Price 130 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Product Type : Wire Mesh

Mesh Type : Steel Wire Mesh

Color : Silver

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry