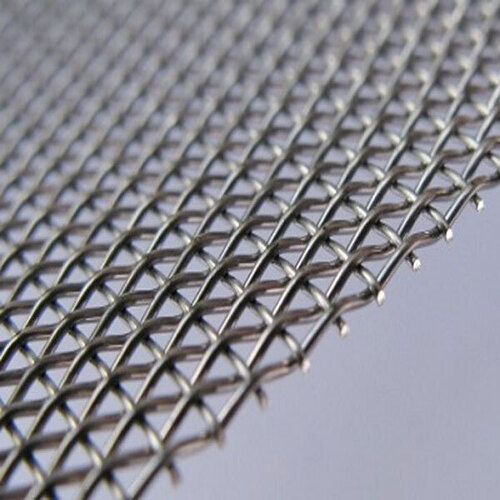

347 Stainless Steel Welded Wire Mesh

Price 50 INR/ Unit

347 Stainless Steel Welded Wire Mesh Specification

- Length

- 30 m (custom lengths available)

- Aperture

- 1/2 inch to 2 inch

- Hole Shape

- Square

- Wire Gauge

- 14 - 18 SWG

- Surface Treatment

- Coated

- Product Type

- Wire Mesh

- Mesh Type

- Welded

- Mesh Style

- Welded Mesh

- Material

- Stainless Steel

- Alloy

- 347 Stainless Steel

- Application

- Other

- Dimensions

- 4 ft x 30 m (standard roll)

- Wire Diameter

- 1.6 mm - 2 mm

- Weight

- 22-30 kg/roll

- Color

- Gray

347 Stainless Steel Welded Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About 347 Stainless Steel Welded Wire Mesh

347 Stainless Steel Welded Wire Meshcan be used as woven wire filter cloth to filter liquid, solid and gas in the filtering industries, such as the filter discs, dipping baskets, filter tubes, test sieves, filter elements or strainers.347 Stainless Steel Welded Wire Meshprovides the most resistive railings as it wears resistivity of heat, acid, and corrosions, etc.347 Stainless Steel Welded Wire Meshhigh resistance makes its applications in a wide range such as chemical industries, mining areas, food industries, and pharmaceutical industries.

These high-quality products are manufactured at our premises using quality tested raw materials and components according to industry quality standards.Indo German Wire Screen Co., we are the professional people delivering high-quality and superior-performance products that have been appreciated by all of our previous customers.

Engineered for Extreme Conditions

347 Stainless Steel Welded Wire Mesh excels in resistance to corrosion, acids, and high temperatures up to 870C, making it a preferred option in chemical plants, furnaces, and other high-demand environments. Its robust tensile strength ensures longevity, even when exposed to intense operational stress. The resistance welding technique delivers firm, reliable joints, contributing to outstanding mesh stability.

Tailored to Project Requirements

This mesh is available in standard rolls of 4 ft x 30 m, but can be customized for length, aperture, and wire gauge to suit diverse project needs. The flexibility of custom sizing, along with a choice of square or alternative hole shapes, renders it suitable for specialized applications in manufacturing, construction, and filtration systems. Efficient packaging further simplifies transportation and storage.

FAQs of 347 Stainless Steel Welded Wire Mesh:

Q: How is 347 Stainless Steel Welded Wire Mesh manufactured to meet ASTM A580/A580M standards?

A: This wire mesh is produced using resistance welding, which ensures strong and consistent joints. Manufactured under ASTM A580/A580M, it guarantees a minimum tensile strength of 550 MPa and excellent performance in high-temperature environments. Precision fabrication checks confirm compliance with the specified industry standards.Q: What applications are ideal for 347 Stainless Steel Welded Wire Mesh?

A: The mesh is ideal for use in settings that demand robust corrosion and acid resistance, such as chemical processing plants, high-temperature furnaces, filtration units, and architectural projects. Its ability to withstand temperatures up to 870C makes it especially useful in environments exposed to heat or aggressive chemicals.Q: When should you choose 347 stainless steel mesh over other alloys?

A: 347 stainless steel is preferred when applications require both superior corrosion resistance and the ability to maintain mechanical integrity at elevated temperatures. It is particularly beneficial in scenarios involving repeated high-temperature cycles and exposure to corrosive media, where alternative materials might degrade.Q: Where can this welded wire mesh be supplied from, and does the exporter offer international shipping?

A: The welded wire mesh is manufactured, exported, and supplied from India. Exporters and suppliers provide both domestic and international shipping, ensuring reliable delivery globally, packaged securely in plastic wrapped rolls.Q: What is the process for requesting custom sizes or specifications for the welded mesh?

A: To request custom sizes, wire gauges, or aperture dimensions, customers should contact the supplier with their specific requirements. The manufacturing process accommodates modifications such as varying mesh styles, roll lengths, and hole shapes to match unique project demands.Q: How can this welded mesh benefit users in demanding industrial environments?

A: With its high tensile strength, excellent resistance to acid and oxidation, and stability at up to 870C, this mesh reduces maintenance needs and increases safety and efficiency. Its robust structure and reliable performance help end users achieve long-term cost savings and operational reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Welded Wire Mesh Category

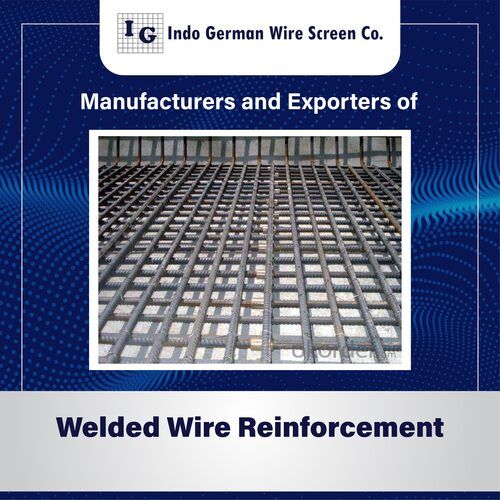

Welded Wire Reinforcement

Price Range 400.00 - 1000.00 INR / Foot

Minimum Order Quantity : 50 Feet

Mesh Style : Wire Cloth

Product Type : Wire Mesh

Material : Other, Metal

321 Stainless Steel Welded Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Welded Mesh

Product Type : Wire Mesh

Material : Stainless Steel

330 Stainless Steel Welded Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Welded Mesh

Product Type : Wire Mesh

Material : Stainless Steel

Wire Mesh Screen

Price Range 400.00 - 1000.00 INR / Foot

Minimum Order Quantity : 50 Feet

Mesh Style : Welded Mesh

Product Type : Wire Mesh

Material : Stainless Steel, Aluminum, Steel, Copper, Iron, Polyester, Galvanized Steel, Metal Alloys

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry