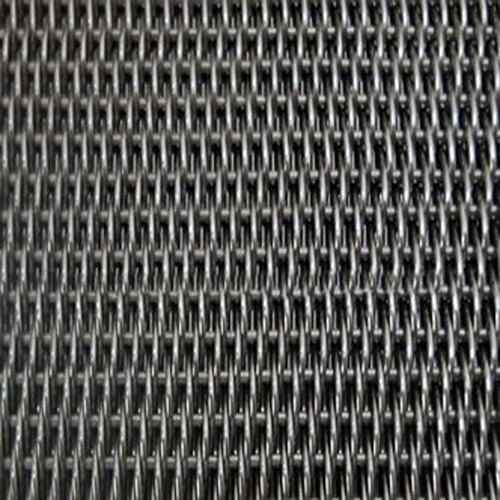

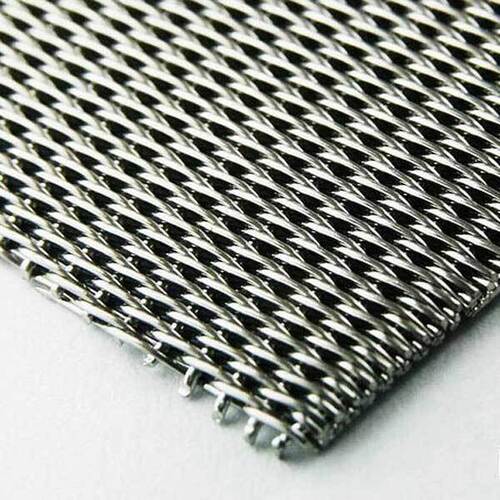

Aluminium Reverse Dutch Weave Wire Mesh

Price 50 INR/ Unit

Aluminium Reverse Dutch Weave Wire Mesh Specification

- Hole Shape

- Rectangular

- Aperture

- 0.02 mm - 2 mm

- Wire Gauge

- 16 Gauge to 30 Gauge

- Surface Treatment

- Coated

- Length

- Up to 30 meters or as required

- Product Type

- Wire Mesh

- Mesh Type

- Reverse Dutch Weave

- Mesh Style

- Plain Mesh

- Material

- Aluminum

- Alloy

- Aluminum 5052 or equivalent

- Application

- Other

- Dimensions

- Customizable as per requirement

- Wire Diameter

- 0.28 mm - 1.65 mm

- Weight

- Lightweight (varies by specification and size)

- Color

- Gray

- Operating Temperature

- Up to 300°C

- Weave Type

- Reverse Dutch Weave

- Corrosion Resistance

- Excellent

- Hardness

- Soft to semi-hard (depending on alloy)

- Finishing Type

- Smooth

- Uses

- Filtration, sieving, separation in chemical, pharmaceutical, and food industries

- Opening Size

- Fine to coarse (precisely controlled for filtration)

- Packing Type

- Rolls, strips, or cut pieces

- Width

- 0.6 m - 1.5 m or as required

Aluminium Reverse Dutch Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Aluminium Reverse Dutch Weave Wire Mesh

Aluminium is a first choice metal for a wide range of industries including marine, automotive, aerospace, and electrical conductivity applications. Aluminium alloys contain magnesium whose addition makes alloy hard and offers good corrosion resistance in marine atmospheres.

Aluminium Reverse Dutch Weave Wire Meshhas more thin warp wires and fewer, but larger, weft wires as this structure provides a high degree of stability and optimal resistance to high pressure.We offer an exclusive range ofAluminium Reverse Dutch Weave Wire Meshat unmatched quality and market leading prices.

Precision Filtration Solution

Our Aluminium Reverse Dutch Weave Wire Mesh offers precise control over aperture sizes, ranging from fine to coarse, enabling superior filtration and separation. This makes it the preferred choice for industrial applications where accuracy is paramount.

Robust and Adaptable Construction

Made from high-quality Aluminum 5052 or equivalent, this wire mesh boasts exceptional corrosion resistance and can withstand operating temperatures up to 300C. Its lightweight yet durable nature ensures ease of handling and long-lasting performance.

Versatile Packaging and Customization

Available in rolls, strips, or custom-cut pieces, our wire mesh can be tailored to specific requirements. Widths range from 0.6 m to 1.5 m, and lengths up to 30 meters or as needed, to fulfill diverse usage demands in various industries.

FAQs of Aluminium Reverse Dutch Weave Wire Mesh:

Q: How is the Aluminium Reverse Dutch Weave Wire Mesh used in industrial filtration processes?

A: This wire mesh is implemented in filtration systems to separate particles with precision. Its controlled aperture sizes and robust structure make it suitable for the chemical, pharmaceutical, and food industries, ensuring efficient sieving and removal of impurities.Q: What customization options are available for dimensions and packaging?

A: Customers can specify their required width (0.6 m to 1.5 m), length (up to 30 meters), aperture size (0.02 mm to 2 mm), and wire gauge (16 to 30). It is supplied as rolls, strips, or cut pieces to match application needs.Q: When should Aluminium Reverse Dutch Weave Wire Mesh be selected over other mesh types?

A: This mesh is ideal when precise filtration and excellent corrosion resistance are necessary, especially in environments exposed to chemicals or high temperatures. Its reverse Dutch weave allows for high mechanical strength while maintaining fine filtrate control.Q: Where can the wire mesh be effectively applied?

A: It can be used across various sectors, notably chemical, pharmaceutical, and food industries, and in equipment where separation, filtration, or sieving processes are essential for product quality and safety.Q: What is the manufacturing process of the Reverse Dutch Weave Mesh?

A: The mesh is produced by weaving aluminum wires in a reverse Dutch pattern, which alternates metal wire diameters and spacing to achieve precise control over the mesh openings. A coating is then applied for added corrosion resistance.Q: How does the excellent corrosion resistance benefit industrial users?

A: Superior corrosion resistance ensures the mesh can operate reliably in harsh chemical environments without rapid degradation, reducing maintenance costs and ensuring sustained filtration performance.Q: What surface treatments are applied to enhance mesh durability?

A: The mesh undergoes specialized coatings that protect against environmental factors and ensure a smooth finish, resulting in a longer lifespan and maintaining efficacy in demanding applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

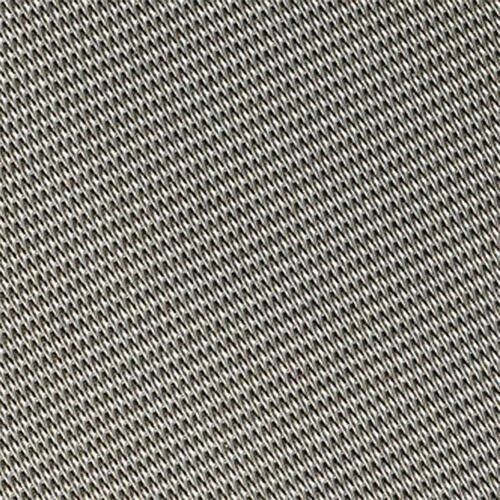

More Products in Reverse Dutch Weave Wire Mesh Category

Mild Steel Reverse Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Type : Other , Reverse Dutch Weave

Product Type : Wire Cloth

Color : Silver

Material : Other, Mild Steel

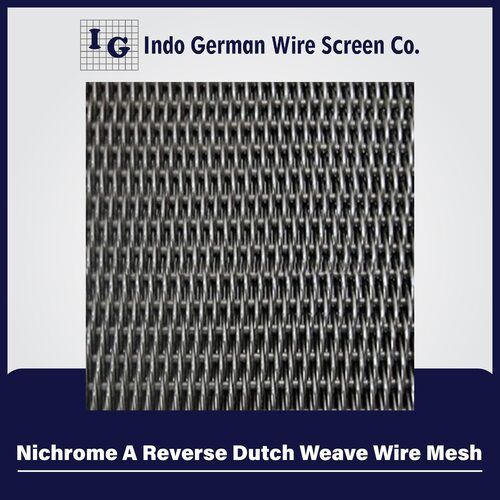

Nichrome A Reverse Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Type : Other , Reverse Dutch Weave

Product Type : Wire Mesh

Color : Silver

Material : Other, Nichrome

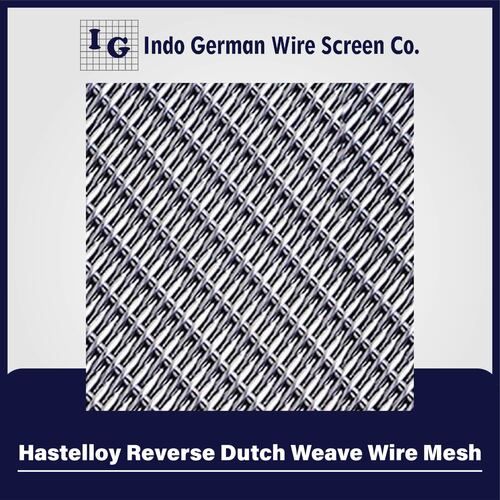

Hastelloy Reverse Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Type : Other , Reverse Dutch Weave

Product Type : Wire Mesh

Color : Silver

Material : Other, Hastelloy

Iron Reverse Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Type : Other , Reverse Dutch Weave

Product Type : Wire Mesh

Color : Silver

Material : Iron

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry