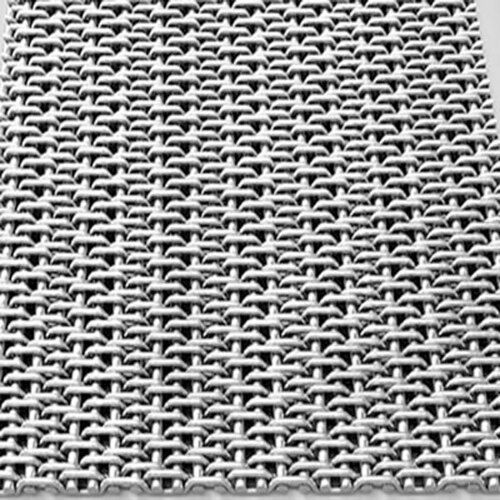

Aluminium Twill Dutch Weave Wire Mesh

Price 50 INR/ Unit

MOQ : 1 Unit

Aluminium Twill Dutch Weave Wire Mesh Specification

- Surface Treatment

- Coated

- Hole Shape

- Round

- Aperture

- Fine, as per Dutch weave standard

- Wire Gauge

- Customizable as per requirement

- Length

- Up to 30 meters

- Product Type

- Wire Mesh

- Mesh Type

- Twill Dutch Weave

- Mesh Style

- Plain Mesh

- Material

- Aluminum

- Alloy

- Aluminium alloy grade 3000/5000 series

- Application

- Other

- Dimensions

- Width up to 1.5 meters

- Wire Diameter

- 0.1 mm 0.8 mm

- Weight

- Lightweight, varies as per dimensions

- Color

- Gray

- Edge Type

- Cut edge or selvedge

- Filtration Precision

- Micron level

- Usage

- Filtration, sieving, industrial screening, chemical, pharmaceutical and food industries

- Tensile Strength

- High

- Packing

- Rolls, wrapped with plastic or wooden case

- Corrosion Resistance

- Excellent

- Weave Type

- Twill Dutch Weave

- Temperature Resistance

- Up to 400°C

Aluminium Twill Dutch Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Aluminium Twill Dutch Weave Wire Mesh

Aluminumis the most popular non-ferrous metal and aluminumalloys are generally used in the wire mesh industry.Aluminumalloys contain magnesium whose addition makes the alloy hard and offers good corrosion resistance in marine atmospheres.This type of weave is made up of a limited number of warp wires interwoven with the maximum number of weft wires, thereby forming a firm and strong cloth. The Aluminium Twill Dutch weave has a high filtering level and high pressure load resistance.Exceptional Filtration Precision

The twill Dutch weave structure enables extremely fine aperture sizes, ensuring micron-level filtration. This makes the aluminium mesh ideal for demanding applications where precise particle separation is essential. Its customizable wire diameter and width provide tailored solutions for specific industrial needs.

Corrosion and Temperature Resistance

Utilizing high-grade aluminium alloy, this mesh provides excellent resistance to corrosion and can maintain its integrity at temperatures reaching up to 400C. The surface is further protected with specialized coatings, ensuring long-term performance in harsh environments.

Versatile Industrial Applications

Aluminium twill Dutch weave mesh is widely used across chemical, pharmaceutical, and food industries for filtration, sieving, and screening. Its lightweight nature and flexible packing options (rolls wrapped in plastic or wooden cases) enhance ease of transport and installation.

FAQs of Aluminium Twill Dutch Weave Wire Mesh:

Q: How does the twill Dutch weave design benefit filtration performance?

A: Twill Dutch weave combines a tight warp and weft pattern, resulting in extremely fine apertures and enhanced strength. This structure enables the mesh to deliver micron-level filtration, making it highly effective for separating fine particles in industrial processes.Q: What is the recommended process for installing aluminium twill Dutch weave mesh?

A: The mesh can be easily installed by unrolling and cutting it to the required size, thanks to its cut edge or selvedge options. Use appropriate mounting or framing methods according to your specific application, ensuring that the coated surface remains intact for optimal durability.Q: When should I choose aluminium mesh over other filtration materials?

A: Aluminium mesh is ideal when requirements include high corrosion resistance, temperature tolerance up to 400C, lightweight handling, and precise micron-level filtration. Its especially suitable for industrial settings that demand reliability and longevity.Q: Where is aluminium twill Dutch weave wire mesh commonly utilized?

A: This mesh finds extensive use in chemical processing, pharmaceutical manufacturing, food industry filtration, and as a protection or sieving medium in diverse industrial screening environments across India and other global markets.Q: What wire gauge and dimensions can be customized for specific needs?

A: Wire diameter can be tailored from 0.1 mm to 0.8 mm, and mesh width is available up to 1.5 meters, with lengths up to 30 meters. These customization options allow the mesh to meet precise engineering and filtration requirements.Q: How does the coated surface treatment enhance mesh performance?

A: The coated surface increases mesh durability by protecting the aluminium from environmental factors and mechanical wear, thereby extending its operational lifespan and maintaining filtration efficiency even in demanding conditions.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Twill Dutch Weave Wire Mesh Category

Monel 400 Twill Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other

Surface Treatment : Coated

Color : Gray

Material : Other, Monel

Steel Twill Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other

Surface Treatment : Coated

Color : Gray

Material : Steel

Stainless Steel Welded Twill Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other

Surface Treatment : Coated, Powder Coating, Galvanized, Painted

Color : Gray

Material : Stainless Steel

Nickel Twill Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other

Surface Treatment : Coated, Powder Coating

Color : Gray

Material : Other, Nickel

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry