Brass Fine Wire Mesh

Price 50 INR/ Unit

Brass Fine Wire Mesh Specification

- Surface Treatment

- Coated

- Length

- 10 Meters

- Wire Gauge

- 30 Gauge

- Aperture

- 0.3 mm

- Hole Shape

- Square

- Product Type

- Wire Mesh

- Mesh Type

- Fine Mesh

- Mesh Style

- Plain Mesh

- Material

- Other

- Alloy

- CuZn37

- Application

- Other

- Dimensions

- 1 Meter Width

- Wire Diameter

- 0.25 mm

- Weight

- 2.5 Kg per Roll

- Color

- Golden

- Usage Area

- Sieving, Filtration, Insect Screens

- Edge Type

- Cut Edge

- Standards

- ASTM E2016-20

- Weave Type

- Plain Weave

- Packaging Type

- Roll

- Operating Temperature

- Up to 300°C

- Finish

- Shiny

- Mesh Count

- 120 Mesh

- Corrosion Resistance

- Excellent

- Tensile Strength

- 350 MPa

Brass Fine Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Brass Fine Wire Mesh

Exceptional Filtration and Sieving Performance

Designed for both industrial and domestic needs, this brass fine wire mesh excels in fine sieving and filtration applications. The uniform mesh opening of 0.3 mm enables efficient separation and screening of materials, ensuring optimal process outcomes in sectors such as chemical, pharmaceutical, and food processing.

Superior Durability and Resistance

Manufactured from CuZn37 alloy, this mesh delivers robust tensile strength of 350 MPa and is coated for enhanced corrosion resistance. Its ability to withstand temperatures up to 300C makes it suitable for demanding filtration and separation environments, providing long-lasting, maintenance-free performance.

FAQs of Brass Fine Wire Mesh:

Q: How do I install the Brass Fine Wire Mesh for sieving or filtration purposes?

A: The mesh is supplied in rolls, allowing you to easily cut it to the desired size. For sieving and filtration, secure the mesh onto a frame or holder, ensuring that the cut edge is safely fixed to prevent unraveling and maintain mesh integrity during use.Q: What are the benefits of using a brass mesh with 120 mesh count and 0.3 mm aperture?

A: A 120 mesh count combined with a 0.3 mm aperture offers fine filtration or sieving, enabling precise separation of small particles. This ensures high efficiency in processes where product purity and consistency are essential.Q: Where is this fine brass wire mesh typically used?

A: This mesh is commonly utilized in sieving, fine filtration, and as insect screens. Industries such as chemical processing, pharmaceuticals, food production, and architectural applications frequently benefit from its versatility and performance.Q: What process is used to manufacture the mesh, and why is the weave type important?

A: The mesh is produced using a plain weave technique, where each wire alternately passes over and under adjacent wires. This process ensures even aperture distribution, strength, and a smooth, uniform mesh surfacecrucial for reliable filtration and extended service life.Q: When should I choose a coated, corrosion-resistant mesh like this brass type?

A: Select this mesh for environments exposed to moisture, chemicals, or high temperatures up to 300C. Its coated, corrosion-resistant surface ensures durability and minimal maintenance, especially in outdoor installations or harsh industrial settings.Q: What advantages does the CuZn37 alloy provide for this mesh?

A: CuZn37 alloy, with a high zinc content, offers excellent mechanical strength and ductility, along with a shiny golden finish. This combination improves the meshs longevity, resistance to wear, and visual appeal.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Fine Wire Mesh Category

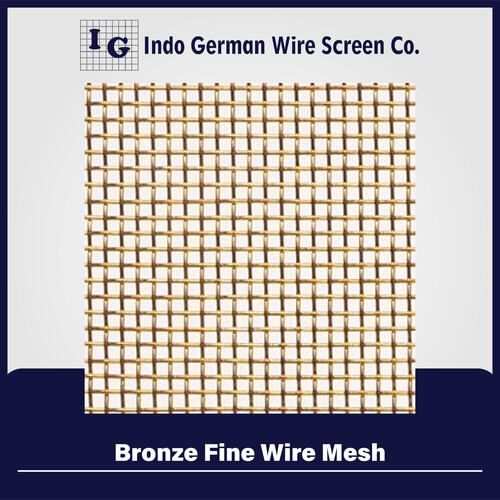

Bronze Fine Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Bronze

Application : Other, Filtration, Sieving, Industrial Screens, Laboratory Use, Decorative Panels

Mesh Type : Other , Woven Mesh

Mesh Style : Other , Plain Weave

Steel Fine Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Application : Other, Filtration, Sieving, Industrial Use

Mesh Type : Other , Fine Mesh

Mesh Style : Woven Mesh

Aluminium Fine Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Application : Other, Filtration, sieving, insect screens, ventilation

Mesh Type : Other , Plain weave

Mesh Style : Other , Woven

Tungsten Fine Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silvergrey

Application : Other, Filtration, catalyst support, high temperature screening, precision electronics

Mesh Type : Other , Ultrafine mesh

Mesh Style : Other , Woven

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry