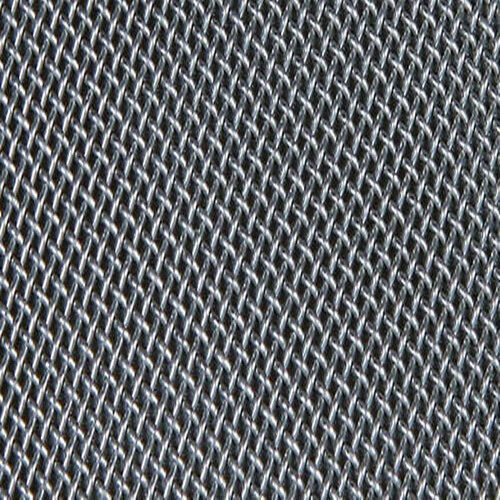

Aluminium Fine Wire Mesh

Price 50 INR/ Unit

Aluminium Fine Wire Mesh Specification

- Length

- Available in rolls of up to 30 meters

- Surface Treatment

- Mill finished

- Hole Shape

- Square

- Wire Gauge

- 10 to 50 SWG

- Aperture

- 0.5 mm to 3 mm

- Product Type

- Fine Wire Mesh

- Mesh Type

- Plain weave

- Mesh Style

- Woven

- Material

- Aluminium

- Alloy

- 1100/3003/5052 series

- Application

- Filtration, sieving, insect screens, ventilation

- Dimensions

- 1 meter to 2 meters width

- Wire Diameter

- 0.18 mm to 1.8 mm

- Weight

- Lightweight (varies by mesh size and gauge)

- Color

- Silver

- Tensile Strength

- 90-150 MPa

- Fire Resistance

- Non-combustible

- Open Area Percentage

- 60% to 85% depending on mesh

- Temperature Range

- -50°C to +200°C

- Corrosion Resistance

- Excellent, suitable for outdoor use

- Packing Type

- Rolls packed in polythene or cartons

- Customization

- Available for width, aperture and roll length

About Aluminium Fine Wire Mesh

Aluminium is the most popular non-ferrous metal and aluminium alloys are generally used in the wire mesh industry. Aluminium alloys contain other elements like copper, magnesium, manganese, or silicon with aluminium. Aluminium is a first choice metal for a wide range of industries including marine, automotive, aerospace, and electrical conductivity applications. Aluminium alloys contain magnesium whose addition makes the alloy hard and offers good corrosion resistance in marine atmospheres.

Versatile Applications

Aluminium Fine Wire Mesh finds extensive use in filtration, sieving, insect screening, and ventilation systems due to its customizable apertures, lightweight nature, and excellent corrosion resistance. Its adaptability ensures it fits both industrial and household requirements effectively.

Customizable for Specific Needs

You can request customized mesh widths (1 to 2 meters), apertures (0.5 mm to 3 mm), and roll lengths (up to 30 meters) to match your exact project specifications. This flexibility makes it suitable for a range of unique applications and installation environments.

Durable and Weather-resistant

Manufactured from high-quality aluminium alloys, the mesh is designed to endure harsh outdoor conditions without corroding. Its non-combustible property and high temperature tolerance make it safe and reliable for use in diverse climates and operational settings.

FAQs of Aluminium Fine Wire Mesh:

Q: How is aluminium fine wire mesh typically used?

A: This mesh is commonly used for filtration, sieving solids and liquids, acting as insect screens, and providing ventilation in residential, commercial, and industrial spaces.Q: What benefits does the high open area percentage offer?

A: A high open area (ranging from 60% to 85%) enhances airflow, improves filtration efficiency, and maintains visibility while offering effective protection against debris and insects.Q: Where can this mesh be installed for optimal performance?

A: It is suitable for both indoor and outdoor applications such as window screens, industrial sieving systems, and ventilation panels due to its excellent corrosion and weather resistance.Q: What is the process for customizing mesh dimensions and apertures?

A: Customization involves specifying your desired mesh width (1 to 2 meters), aperture size (0.5 mm to 3 mm), and roll length (up to 30 meters); the manufacturer or exporter will then produce the wire mesh to these requirements.Q: What makes this wire mesh suitable for outdoor use?

A: Its corrosion resistance, tolerance for temperatures from -50C to +200C, and non-combustible nature enable it to withstand harsh weather conditions, making it ideal for outdoor installations.Q: How is the mesh typically packed for shipping and supply?

A: The mesh is supplied in rolls, which are securely packed in polythene wrapping or cartons to protect them during transportation and storage.Q: What is the range of wire diameters and gauges available?

A: Wire diameters range from 0.18 mm to 1.8 mm, and wire gauges span 10 to 50 SWG, allowing for a variety of mesh strengths and applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Fine Wire Mesh Category

Brass Fine Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Type : Other , Fine Mesh

Mesh Style : Plain Mesh

Color : Golden

Application : Other

Tungsten Fine Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Type : Other , Ultrafine mesh

Mesh Style : Other , Woven

Color : Silvergrey

Application : Other, Filtration, catalyst support, high temperature screening, precision electronics

Monel 400 Fine Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Type : Other , Fine Mesh

Mesh Style : Woven Mesh

Color : Metallic Grey

Application : Other, Filtration, Chemical Processing, Marine, Aerospace, Oil & Gas

Mild Steel Fine Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Type : Other , Fine Wire Mesh

Mesh Style : Woven Mesh

Color : Metallic Silver

Application : Other, Filtration, Screening, Industrial Use, Construction

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry