Brass Rectangular Wire Mesh

Price 50 INR/ Unit

Brass Rectangular Wire Mesh Specification

- Surface Treatment

- Coated

- Hole Shape

- Rectangle Hole

- Product Type

- Wire Mesh

- Mesh Type

- Brass Wire Mesh

- Material

- Brass

- Application

- Other

- Color

- Golden

Brass Rectangular Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Brass Rectangular Wire Mesh

Brass is an alloy of copper and zinc and has improved resistance to abrasion and corrosion. Compared to copper, Brass has low electrical conductivity and is frequently used in sieving diversified pellets, powder, porcelain clay and glass, chinaware printing, filtering liquid and gas.Brass Rectangular Wire Mesh or Brass Rectangular Wire Nettingis a welded wire mesh panel specifically manufactured by welding thin and thick diameter wires to form a Rectangular mesh hole.Brass Rectangular Wire cloth plain weaveis the most frequently used weave in which each warp wire crosses interchangeably above and below each weft wire. Warp wires and weft wires usually have the same diameter.Brass Rectangular Wire Meshis easy to work with and is available in different hole sizes, thickness and other configurations in order to meet your specific application requirements. We offer an exclusive range ofBrass Rectangular Wire Meshat unmatched quality and market leading prices.

Expertly Crafted Brass Mesh Solutions

We specialize in producing and supplying high-quality Brass Rectangular Wire Mesh, designed for strength and elegance. Our meshes, finished with a protective coating, maintain their appearance and functionality in demanding environments. Whether you need tailored sizing or standard specifications, we cater to different industry needs with a commitment to quality and timely delivery from India.

Versatile Applications and Customization

Our coated brass wire mesh serves a variety of purposes, including filtration, architectural elements, screens, and decorative features. The rectangular holes provide unique structural options, while the golden color enhances aesthetic value. We offer customization in mesh size, dimensions, and coating based on your project requirements, ensuring optimal performance and visual appeal.

FAQs of Brass Rectangular Wire Mesh:

Q: How is brass rectangular wire mesh manufactured and coated?

A: Brass rectangular wire mesh is produced by weaving high-purity brass wires into a grid with rectangle-shaped holes. After weaving, the mesh undergoes a coating process to enhance its durability, corrosion resistance, and golden finish, ensuring long-term performance and visual appeal.Q: What are the typical uses of coated brass rectangular wire mesh?

A: This mesh is extensively used in filtration systems, architectural facades, partitions, insect screens, and decorative installations. Its unique rectangular holes and golden appearance make it suitable for both functional and aesthetic applications across diverse industries.Q: When should I choose brass rectangular wire mesh over other materials?

A: Opt for brass rectangular wire mesh when you require excellent corrosion resistance, superior conductivity, and an attractive golden look. It is especially beneficial in environments where durability and both decorative and functional properties are desired, such as architectural and industrial settings.Q: Where are your brass wire mesh products manufactured and supplied from?

A: We manufacture, export, supply, and trade brass rectangular wire mesh from our facilities in India, serving both domestic and international clients with reliable product quality and timely fulfillment.Q: What is the process for ordering customized brass rectangular wire mesh?

A: To order customized mesh, share your preferred specificationssuch as hole size, wire diameter, mesh dimensions, and coating type. We will then manufacture the product according to your requirements and deliver it, ensuring it meets your projects specific needs.Q: How does the surface coating on the mesh benefit its performance?

A: The coating applied to the brass mesh acts as a protective barrier, preventing oxidation, enhancing corrosion resistance, and maintaining the meshs vibrant golden color, thereby extending its lifespan and improving its suitability for demanding applications.Q: What advantages does rectangle hole mesh offer compared to square hole or other shapes?

A: Rectangle hole mesh provides unique structural benefits such as improved directional strength, higher open area for filtration, and distinctive aesthetic appeal, making it preferable for certain engineering, screening, and decorative purposes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rectangular Wire Mesh Category

Nickel Rectangular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Coated

Material : Other

Color : Silver

Product Type : Wire Mesh

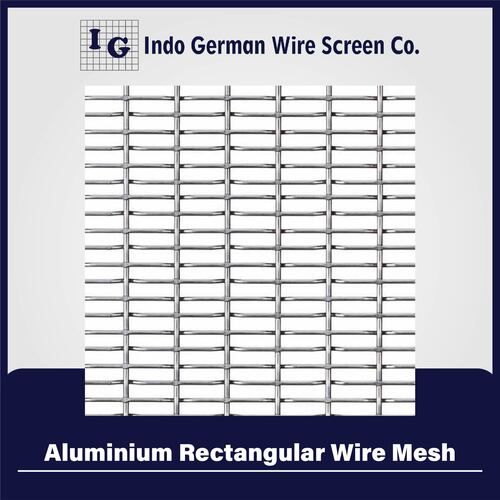

Aluminium Rectangular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Coated

Material : Aluminum

Color : Silver

Product Type : Wire Mesh

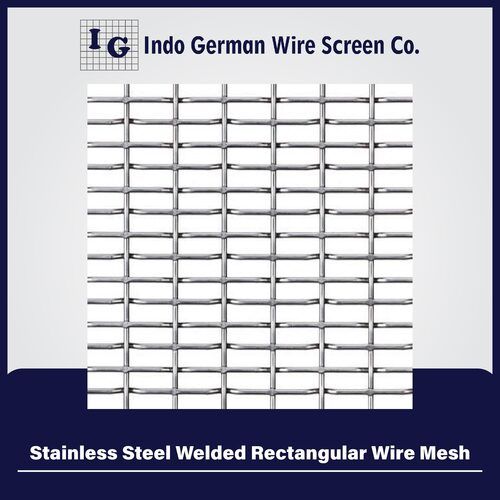

Stainless Steel Welded Rectangular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Coated

Material : Stainless Steel

Color : Silver

Product Type : Wire Mesh

Copper Rectangular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Coated

Material : Copper

Color : Copper

Product Type : Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry