Nickel Rectangular Wire Mesh

Price 50 INR/ Unit

Nickel Rectangular Wire Mesh Specification

- Hole Shape

- Rectangle Hole

- Surface Treatment

- Coated

- Product Type

- Wire Mesh

- Mesh Type

- Other

- Mesh Style

- Plain Mesh

- Material

- Other

- Application

- Other

- Color

- Silver

Nickel Rectangular Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Nickel Rectangular Wire Mesh

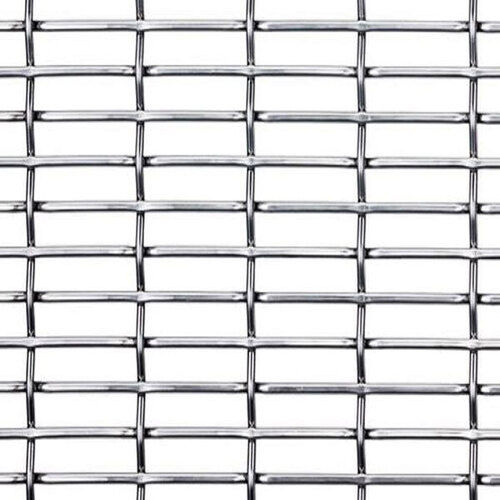

Nickel is a silvery-white hard metal whose strength, ductility and resistance to heat and corrosion make it exceptionally useful for the manufacturing of a wide range of materials from wires to coins to military equipment. Nickel is woven using high purity nickel wire and is mostly favoured in corrosive environments such as filtration of liquids, gas, etc.Nickel Rectangular Wire cloth plain weaveis the most frequently used weave in which each warp wire crosses interchangeably above and below each weft wire. Warp wires and weft wires usually have the same diameter.We offer an exclusive range ofNickel Rectangular Wire Meshat unmatched quality and market leading prices.

Premium Coated Nickel Mesh for Industrial Applications

Specialized in exporting and manufacturing coated nickel rectangular wire meshes, we offer durable mesh with a rectangle hole structure and plain style. The silver coating enhances both appearance and corrosion resistance, making these meshes suitable for demanding operations such as filtration, separation, and screening in chemical, pharmaceutical, and energy sectors.

Reliable Indian Supplier with Global Reach

As a leading supplier and trader from India, we ensure a consistent supply of nickel rectangular wire mesh to industries worldwide. Our strong logistics network and manufacturing expertise allow us to meet custom requirements and deliver orders efficiently, maintaining quality standards at every step.

FAQs of Nickel Rectangular Wire Mesh:

Q: How is the nickel rectangular wire mesh manufactured?

A: The mesh is produced using high-purity nickel wires woven in a plain mesh style to create rectangular holes. After weaving, a special coating is applied for enhanced durability and corrosion protection.Q: What are the main uses of this wire mesh?

A: Nickel rectangular wire mesh is primarily used in filtration, screening, and separation processes across industries such as chemical processing, pharmaceuticals, energy, and water treatment due to its high corrosion resistance and strength.Q: When should I choose coated nickel mesh over uncoated alternatives?

A: Coated nickel mesh is particularly beneficial in environments where enhanced corrosion resistance and longer service life are essential, such as in chemical exposure or high-humidity applications.Q: Where can your nickel rectangular mesh be supplied?

A: We export and supply our nickel rectangular wire mesh from India to clients worldwide, serving both domestic and international markets with efficient logistics support.Q: What is the process for ordering customized mesh specifications?

A: To order custom sizes or specifications, you can contact our sales team with your requirements. We offer tailored solutions regarding mesh size, rectangle hole dimensions, and surface treatments to match your applications needs.Q: How does the rectangular hole shape benefit industrial processes?

A: Rectangular holes provide higher open area and improved flow compared to square meshes, making them ideal for applications that demand efficient filtration or separation of materials.Q: What advantages does the silver-coated surface provide?

A: The silver-coated surface enhances the meshs appearance and protects the nickel substrate from oxidation and wear, thus extending the meshs operational life in harsh industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rectangular Wire Mesh Category

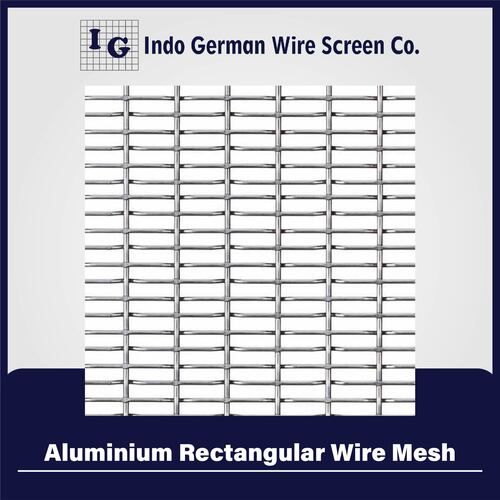

Aluminium Rectangular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Coated

Color : Silver

Mesh Type : Aluminum Wire Mesh

Material : Aluminum

Copper Rectangular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Coated

Color : Copper

Mesh Type : Copper Wire Mesh

Material : Copper

Steel Rectangular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Coated

Color : Silver

Mesh Type : Steel Wire Mesh

Material : Steel

Tungsten Rectangular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Coated

Color : Silver

Mesh Type : Other , Tungsten Wire Mesh

Material : Other, Tungsten

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry