Copper Perforated Sheets

Price 50 INR/ Unit

Copper Perforated Sheets Specification

- Usage

- Industrial

- Material

- Copper

- Size

- Standard

- Type

- Perforated Sheets

- Product Type

- Copper Perforated Sheets

- Color

- Copper

Copper Perforated Sheets Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Copper Perforated Sheets

Perforated Sheetsare thin sheets which are stamped, fabricated, or punched to create a pattern of holes, slots, and various aesthetic shapes to have uniform perforations throughout the entire surface. Depending on applications and requirements, patterns of perforated sheets can be round-staggered, round-straight, slotted holes. Although the process of perforating improves the exterior of metals, it has other useful special uses like protection and noise suppression.Theperforated sunshades and claddingsprovides privacy for the building residents without any view obstruction while controlling interior climate thus reducing the load of air conditioning and saving energy to a large extent.Perforated Sheetsfences and banisters keep enclosed machines and other properties from damage secure and the safety of people.Indo German Wire Screen Co.has the in-house fabrication capabilities to provide custom perforated hole patterns for unique or specialty applications, if required.

Robust Industrial Application

Copper Perforated Sheets are designed to meet demanding industrial requirements, from filtration systems to architectural features. Their engineered perforations provide effective ventilation and allow customization according to specific project needs. The materials inherent corrosion resistance ensures long-term reliability even in challenging environments.

Quality Assurance and Export Expertise

As a trusted exporter, manufacturer, supplier, and trader in India, we uphold strict quality standards throughout our production process. Our copper perforated sheets meet international benchmarks, offering clients reliable and consistent performance. We deliver to both domestic and global markets, with a focus on customer satisfaction and timely supply.

FAQs of Copper Perforated Sheets:

Q: How are Copper Perforated Sheets manufactured?

A: Copper Perforated Sheets are produced using advanced perforation techniques that involve punching precise holes into copper sheets. The process utilizes automated machinery to ensure uniformity and accuracy, resulting in sheets that meet industry standards for strength and performance.Q: What are the main industrial uses of Copper Perforated Sheets?

A: These sheets are widely used in filtration, ventilation, construction, acoustic panels, and decorative installations. Their durability and excellent thermal conductivity make them suitable for applications where both utility and appearance are important.Q: Where can I source Copper Perforated Sheets in standard sizes?

A: Copper Perforated Sheets in standard sizes are available from reputed exporters, manufacturers, suppliers, and traders in India. Our company provides nationwide service and international shipping for bulk and custom orders.Q: When should Copper Perforated Sheets be preferred over other materials?

A: Copper Perforated Sheets should be considered when your application demands superior corrosion resistance, electrical or thermal conductivity, and an attractive finish. They perform exceptionally well in environments exposed to moisture and fluctuating temperatures.Q: What benefits do Copper Perforated Sheets offer in industrial usage?

A: Copper Perforated Sheets deliver improved ventilation, efficient filtration, and an aesthetically pleasing appearance. They are highly resistant to rust, durable for long-term use, and easy to fabricate, making them a practical choice for diverse industrial purposes.Q: What is the process for exporting Copper Perforated Sheets from India?

A: Exporting Copper Perforated Sheets involves quality checks, packaging, documentation, and shipping according to international trade regulations. As an experienced exporter, we handle all aspects to ensure safe and timely delivery to clients worldwide.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Copper Perforated Sheets Category

Copper Round Hole Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Other , Polished, Bright Finish

Thickness : 0.5mm to 3mm (customizable)

Technique : Other, Cold Rolled, Perforated

Feature : Corrosion Resistance, High Electrical Conductivity, Smooth Surface Finish, Precise Perforation

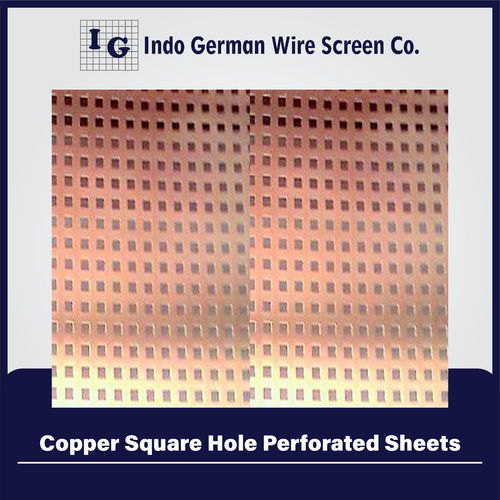

Copper Square Hole Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Other , Polished/Uncoated

Thickness : 0.5 mm to 3 mm

Technique : Other, Perforation

Feature : Corrosion Resistance, High Ductility, Thermal and Electrical Conductivity

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry