Copper Round Hole Perforated Sheets

Price 50 INR/ Unit

MOQ : 1 Unit

Copper Round Hole Perforated Sheets Specification

- Surface Treatment

- Polished, Bright Finish

- Process

- Mechanical Perforation

- Temper

- Soft (Annealed) / Half Hard

- Standard

- ASTM B152, IS 191

- Shape

- Rectangular, Square Sheets

- Material

- Pure Copper (Cu >99%)

- Type

- Round Hole Perforated Sheet

- Technique

- Cold Rolled, Perforated

- Thickness

- 0.5mm to 3mm (customizable)

- Application

- Architecture, Filtration, Screening, EMI/RFI Shielding, Decorative Panels, Ventilation Systems

- Feature

- Corrosion Resistance, High Electrical Conductivity, Smooth Surface Finish, Precise Perforation

- Minimum Order Quantity

- As per Client Requirement

- Hole Diameter

- 0.5mm to 20mm, Customizable

- Electrical Conductivity

- > 58 MS/m

- Packaging

- Wooden Pallets or Customized

- Sheet Size

- 600mm x 2400mm / Custom Sizes Available

- Hole Pattern

- 60° Staggered / Straight

- Color

- Reddish Brown

- Edge Finish

- Smooth, Burr-Free

- Open Area Percentage

- 10% - 60% (as per requirement)

- Density

- 8.94 g/cm³

About Copper Round Hole Perforated Sheets

Copper is ductile, malleable and has high thermal and electrical conductivity. Copper is resistant to atmospheric corrosion but is attacked by oxidizing agents such as nitric acid, ferric chloride, cyanides, and ammonia acid compounds. Copper when exposed to the atmosphere will naturally develop a thin green layer, known as patina. Copper wire meshs unique colour makes it a very popular option for many different types of users, including designers, artists, architects and homeowners. Copper Round Hole Perforated Sheets contain round hole patterns that can be staggered or straight lines. Staggered patterns put the holes out of alignment, while a straight line has holes arranged parallel and perpendicular to each other. There are three options for end margins, which include finished, unfinished, and blank. Finished margins are uniform and complete whereas unfinished margins are not solid at the edge of the sheet.Exceptional Precision and Durability

Our copper round hole perforated sheets boast precise mechanical perforation, resulting in uniform holes and smooth finishes. The use of pure copper guarantees high electrical conductivity and robust corrosion resistance, lending durability and functional quality for demanding environments.

Versatile Customization Options

With customizable hole diameters (0.5 mm to 20 mm), open area (10%60%), thickness (0.5 mm to 3 mm), sheet sizes, and patterns, these sheets adapt seamlessly to architectural, industrial, and decorative projects. Edge finishing ensures safety and quality, supported by compliance with ASTM B152 and IS 191 standards.

Wide Range of Applications

Ideal for architecture, ventilation systems, EMI/RFI shielding, screening, and filtration, the copper perforated sheets combine utility with aesthetic appeal. Their reddish-brown color and polished surfaces bring elegance to decorative panels while supporting advanced engineering uses.

FAQs of Copper Round Hole Perforated Sheets:

Q: How are copper round hole perforated sheets manufactured?

A: These sheets are produced using mechanical perforation on cold rolled pure copper, resulting in precise round holes with burr-free, smooth edges. The process ensures high-quality finish and accurate open area percentages as per client requirements.Q: What customization options are available for hole diameter and sheet size?

A: Hole diameters can range from 0.5 mm to 20 mm, and sheet sizes are typically 600 mm x 2400 mm. Both featuresalong with patterns, thickness, and open areacan be tailored according to specific project needs.Q: Where can these copper perforated sheets be used?

A: They are suitable for use in architecture, filtration, screening, EMI/RFI shielding, decorative panels, and ventilation systems due to their corrosion resistance, smooth surface finish, and electrical conductivity.Q: What are the benefits of a 60 staggered or straight hole pattern?

A: A 60 staggered pattern provides uniform strength and maximized open area, while straight patterns offer a classic, symmetrical look. Both options enhance function and aesthetic value depending on application demands.Q: How does the pure copper composition affect performance?

A: Having over 99% copper content ensures superior electrical conductivity (>58 MS/m) and excellent corrosion resistance, making these sheets ideal for technical and decorative uses that require both functionality and longevity.Q: What is the packaging and minimum order quantity for these sheets?

A: Sheets are securely packaged on wooden pallets or customized packing as needed. Minimum order quantities are established per client requirements to ensure flexibility for various project scales.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Copper Perforated Sheets Category

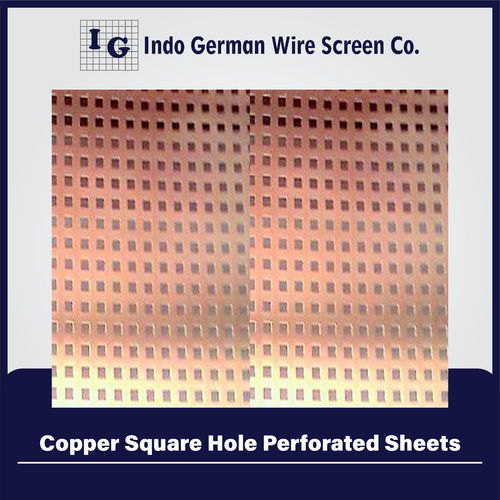

Copper Square Hole Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other , Copper

Type : Perforated Sheet

Process : Cold Rolled, Hot Rolled

Temper : Soft, Half Hard, Hard

Copper Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other , Copper

Type : Perforated Sheets

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry