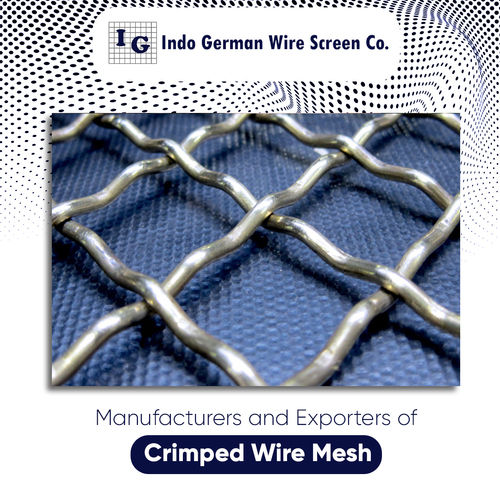

Crimped Wire Mesh

Crimped Wire Mesh Specification

- Aperture

- as per specification or requirement

- Hole Shape

- Square

- Wire Gauge

- as per requirement

- Length

- as per requirement

- Surface Treatment

- Polished

- Product Type

- Wire Mesh

- Mesh Type

- Steel Wire Mesh

- Mesh Style

- Crimped

- Material

- Steel

- Alloy

- Non-alloy or mild steel (unless otherwise specified)

- Application

- Mining, Fencing, Construction, Sieving, Quarry Screens, Decorative

- Dimensions

- Custom Size/Standard Roll

- Wire Diameter

- 2 mm - 8 mm (typical)

- Weight

- Depends on dimension and gauge

- Color

- Silver

Crimped Wire Mesh Trade Information

- Minimum Order Quantity

- 10 Square Foots

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 10 Square Foots Per Day

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Packaging Details

- Carton Box

- Main Export Market(s)

- Australia, Central America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia, North America

- Main Domestic Market

- All India

About Crimped Wire Mesh

Ever since our inception, we are successfully manufacturing and supplying a wide range of Crimped Wire Mesh. This wire mesh is used in mines, coal factory and construction industry for several applications. The mesh that we offer is designed by utilizing superior quality materials under the supervision of our professionals at our well equipped production unit. This Crimped Wire Mesh is properly examined by our quality controllers before delivering to valuable customers and availed at best market price.

Features ofCrimped Wire Mesh:

- Excellent design

- Durable quality

- Light weight

Product details

|

Weave Type |

Hexagonal,Twill |

|

Material |

SS304,SS316,Coarse SS |

|

Mesh Size |

0-10 per inch |

Superior Strength and Customization

Our crimped wire mesh is manufactured to deliver robust tensile strength, conforming to IS standards. Whether you opt for double or single crimped weaves, custom dimensions are available along with varied wire gauges and aperture sizes. Each mesh is produced with care, offering flexibility for both industrial and decorative uses.

Resilient & Versatile Applications

With its capability to perform at temperatures up to 400C and a polished finish ensuring corrosion resistance, this steel wire mesh adapts to demanding environments. Use it for mining, fencing, construction, sieving, or as quarry screens. Its sturdy construction and multiple edge options mean reliability for every project.

FAQs of Crimped Wire Mesh:

Q: How is crimped wire mesh manufactured to ensure high tensile strength?

A: Crimped wire mesh is woven using precision-machined steel wires, employing either double or single crimp processes. This method enhances the meshs structure, resulting in high tensile strength that meets IS standards, making it suitable for demanding industrial applications.Q: What edge types are available for crimped wire mesh, and how do they impact usage?

A: Customers can choose between cut edge or fold edge finishes. Cut edges provide a clean, straight termination ideal for applications where the mesh will be framed, while fold edges add extra strength and safety, especially for installations in exposed areas.Q: Where is crimped wire mesh commonly used?

A: This wire mesh is widely utilized in mining, fencing, construction, sieving, quarry screens, and decorative architectural projects. Its strength and adaptability allow it to function in environments where durability and reliability are essential.Q: What customization options are offered for wire diameter, aperture, and dimensions?

A: Wire diameter, aperture shape (square or other), and overall mesh dimensions can be tailored to specific requirements. Clients can specify custom sizes, wire gauges (from 2 mm to 8 mm), and desired aperture measurements to fit their projects needs.Q: How does the polished finish enhance corrosion resistance of the mesh?

A: A polished finish is applied to the steel wire mesh to create a barrier against moisture and environmental factors. This process significantly reduces the risk of rust and surface degradation, ensuring a longer service life in harsh conditions.Q: Is crimped wire mesh suitable for high temperature environments?

A: Yes, steel crimped wire mesh is designed to withstand operational temperatures up to 400C, making it suitable for industrial operations involving heat, such as sieving and screening in mining or quarrying industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh Category

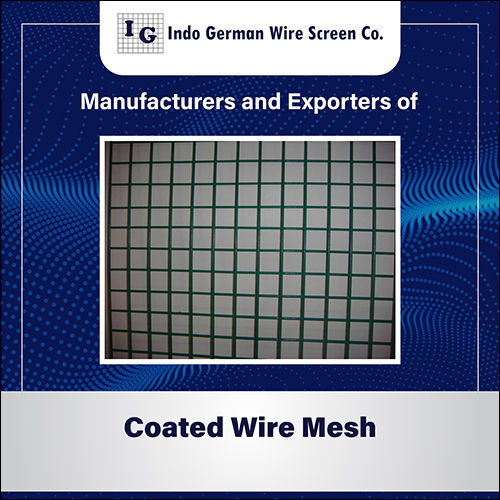

Coated Wire Mesh

Price Range 50.00 - 100.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Color : Black

Mesh Type : Steel Wire Mesh

Product Type : Wire Mesh

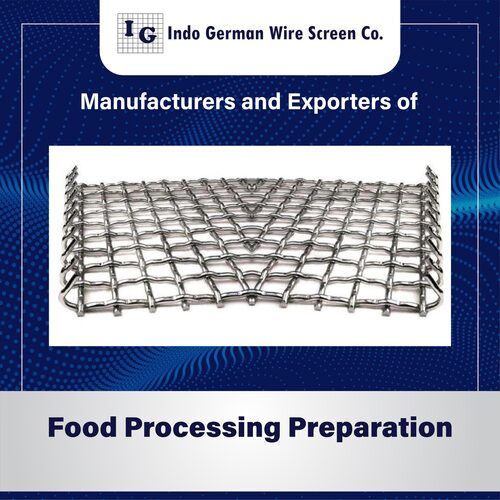

Wire Mesh For Food Processing Preparation

Color : Sliver

Mesh Type : Iron Wire Mesh

Product Type : Wire Mesh

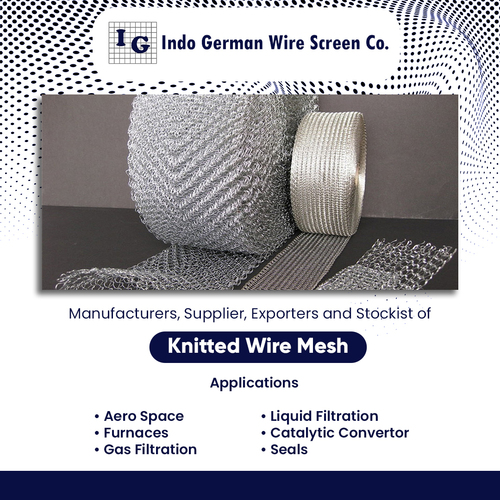

Knitted Wire Mesh

Price Range 325.00 - 450.00 INR / Kilograms

Minimum Order Quantity : 10 Kilograms

Color : Silver

Mesh Type : Other , knitted wire net

Product Type : Wire Mesh

Galvanized Barbed Iron Wire

Price Range 58.00 - 75.00 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Color : Silver

Mesh Type : Steel Wire Mesh

Product Type : Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry