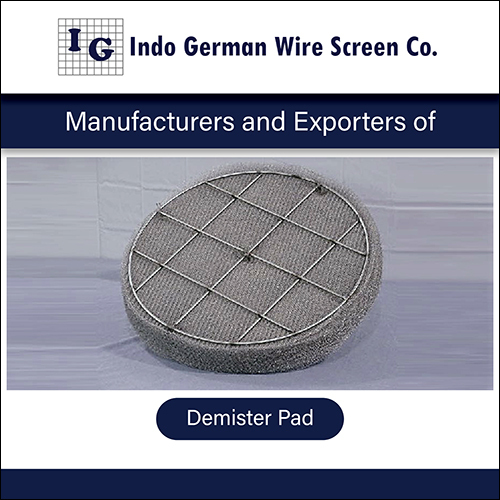

Demister Pad

Price 7500 INR/ Piece

Demister Pad Specification

- Length

- Customizable as per requirement

- Surface Treatment

- Polished

- Aperture

- 2 mm to 6 mm

- Hole Shape

- Square

- Wire Gauge

- Available in 0.16 mm to 0.50 mm

- Product Type

- Wire Mesh

- Mesh Type

- Steel Wire Mesh

- Mesh Style

- Knitted Mesh

- Material

- Stainless Steel

- Alloy

- 304/316 stainless steel

- Application

- Gas-liquid separation, filtration, oil and gas industry, petrochemical

- Dimensions

- Custom sizes available

- Wire Diameter

- 0.20 mm - 0.50 mm

- Weight

- Dependent on dimensions and material

- Color

- Black

- Operating Temperature

- Up to 600°C

- Corrosion Resistance

- Excellent

- Installation Method

- Drop-in or fitted type

- Packing Type

- Wooden box or as required

- Density

- 128 kg/m³ (standard) or customizable

- Shape

- Round or Rectangular

Demister Pad Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Packaging Details

- Carton Box

- Main Export Market(s)

- Middle East

- Main Domestic Market

- All India

About Demister Pad

By keeping records of latest demands in the market, we manufacture and export the finest quality grade of Demister Pad. Our entire range is designed by utilizing superior quality materials under the guidance of experts at well equipped production unit. This pad has durable strength and used for sealing vapor-liquid separator vessels in several industries. Prior to delivery, it is examined on several standards by our quality controllers. This Demister Pad can be availed at best market price by our customers.

Features:

- High strength

- Excellent design

- Easy to fix

Product details

| Case Material | SS |

| Size | 32 inches |

| Material Grade | SS( 304 /306) |

| Type | Woven |

| Filter Rating | 99% |

Outstanding Corrosion Resistance

Engineered from premium stainless steel alloys (304/316), the demister pad is highly resistant to corrosion, making it suitable for demanding environments in oil, gas, and petrochemical plants. Its robust construction ensures long-term durability even when exposed to harsh chemicals and elevated temperatures.

Flexible Design and Installation

Choose from round or rectangular shapes and a wide range of customizable dimensions to fit your application perfectly. Installation is straightforward, with options for drop-in or fitted types, allowing for hassle-free incorporation into existing systems. Each pad is packed securely in wooden boxes or as per customer requirements.

Optimized Performance for Gas-Liquid Separation

With mesh styles including steel wire knitted mesh and options for hole shape and aperture, these demister pads provide superior removal of entrained liquids from gas streams. The design minimizes pressure drop while maximizing separation efficiency, making them vital for maintaining process purity and operational safety.

FAQs of Demister Pad:

Q: How is the demister pad installed in gas-liquid separation systems?

A: The demister pad can be installed using either drop-in or fitted type methods, depending on your systems requirements. Both installation options allow for quick setup and easy integration into existing equipment.Q: What are the benefits of using stainless steel demister pads in filtration applications?

A: Stainless steel demister pads provide excellent corrosion resistance, high temperature tolerance up to 600C, and long-lasting performance. Their robust mesh structure ensures effective filtration and gas-liquid separation across various industrial settings.Q: When should I customize the size and density of a demister pad?

A: Customizing the pads size and density is recommended when dealing with unique operational requirements or specialized equipment. Standard density is 128 kg/m, but adjustments can be made to optimize efficiency and fit based on your specific application.Q: Where are demister pads typically used?

A: Demister pads are widely applied in the oil and gas industry, petrochemical plants, and filtration systems where gas-liquid separation is critical for process efficiency and equipment reliability.Q: What is the typical process for ordering a demister pad according to my specifications?

A: You can specify shape, dimensions, wire gauge (0.16 mm to 0.50 mm), aperture, mesh style, and packing type when ordering. Manufacturers in India provide export, supply, and custom fabrication options to meet your exact requirements.Q: How does the surface treatment and material choice affect demister pad performance?

A: A polished surface treatment enhances durability and reduces fouling risk. Choosing high-quality stainless steel alloys like 304 or 316 ensures longevity, superior strength, and optimal corrosion resistance in challenging environments.Q: What usage advantages do knitted mesh styles offer in demister pads?

A: Knitted mesh ensures thorough capture of liquid droplets within gas streams, thus improving separation efficiency, minimizing product loss, and maintaining process purity in filtration and separation units.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Demister Pad Category

Mist Eliminator Demister

Surface Treatment : Other, Galvanized/Polished/Custom

Material : Steel

Hole Shape : Square Hole

Mesh Type : Iron Wire Mesh

Product Type : Wire Mesh

Length : Customized lengths

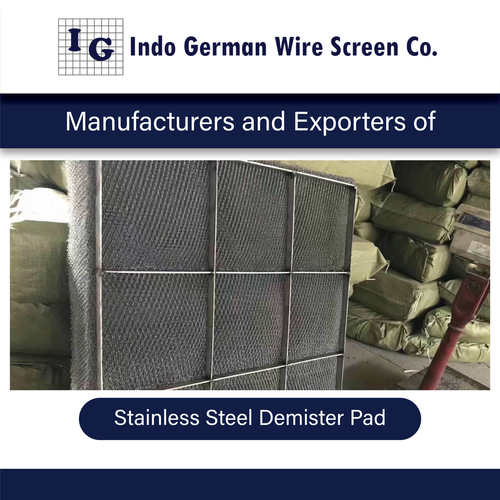

Stainless Steel Demister Pad

Surface Treatment : Polished

Material : Steel

Hole Shape : Square Hole

Mesh Type : Iron Wire Mesh

Product Type : Wire Mesh

Length : Up to 6000 mm or as specified

Carbon Steel Demister Pad

Surface Treatment : Polished

Material : Steel

Hole Shape : Square Hole

Mesh Type : Iron Wire Mesh

Product Type : Wire Mesh

Length : Customized, as per order

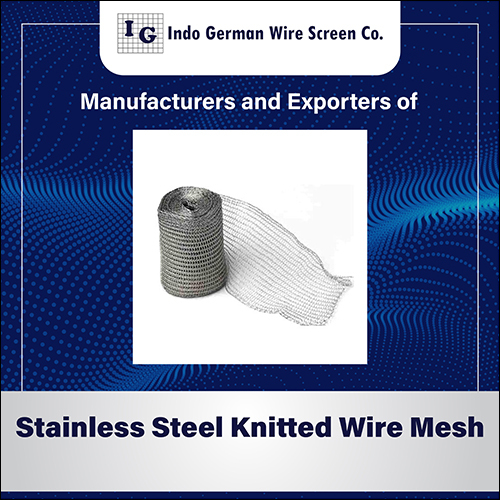

Knitted Wire Mesh Demister Pad

Surface Treatment : Polished

Material : Other, Carbon Steel, SS

Hole Shape : Square Hole

Mesh Type : Steel Wire Mesh

Product Type : Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry