Mist Eliminator Demister

Mist Eliminator Demister Specification

- Wire Gauge

- Available as per requirement

- Surface Treatment

- Galvanized/Polished/Custom

- Length

- Customized lengths

- Hole Shape

- Square Hole

- Aperture

- As per application

- Product Type

- Wire Mesh

- Mesh Type

- Iron Wire Mesh

- Mesh Style

- Knitted

- Material

- Steel

- Alloy

- Carbon Steel/Iron

- Application

- Mist removal, liquid-gas separation, filtration

- Dimensions

- Custom sizes available

- Wire Diameter

- Variable (commonly 0.1 mm to 0.5 mm)

- Weight

- Depends on size and material thickness

- Color

- Sliver

- Operational End Use

- Petrochemical, Chemical Process, Power Generation, Environmental

- Packing Type

- Rolls, Sheets, or Custom shapes

- Porosity

- High (Optimized for maximum mist separation)

- Corrosion Resistance

- High due to galvanized/coated surface

- Service Life

- Long-Life under normal operating conditions

- Temperature Resistance

- Up to 400°C

- Installation Type

- Interlocking/Panel mounted

- Max Pressure Drop

- Low, optimized for process efficiency

Mist Eliminator Demister Trade Information

- Minimum Order Quantity

- 5 Pieces

- FOB Port

- Mumbai ( India)

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 1 Days

- Main Domestic Market

- All India

- Certifications

- Test Certification available at the time of dispatch.

About Mist Eliminator Demister

Our company is also engaged in the manufacturing, supplying, trading and exporting high efficiency Mist Eliminator Demister. Our offered pad is used for removing mist and entrained liquids from the gas flow in the industries. Our huge list of clients highly appreciate this pad for their excellent finish and optimum quality. This Mist Eliminator Demister is manufactured from different metals such as monel, nickel, copper, P.T.F.E. and H.D.P.E. This type of pad finds applications in various automotive industries for filtration of various materials.

Features:

- Corrosion resistance

- High endurance

- Sturdiness

- Superior strength

Optimized Mist Separation for Industrial Applications

Designed for use in challenging environments like petrochemical, chemical, and power generation sectors, these demisters efficiently separate mists and droplets from gas streams. Their high porosity mesh and low pressure drop deliver effective filtration without compromising flow rates, ensuring operational reliability and resource savings.

Robust Construction with Customizable Options

Available in rolls, sheets, and custom shapes, our demisters feature iron or carbon steel mesh, treated with galvanized or polished finishes for enhanced durability and corrosion resistance. Clients can specify wire gauge, aperture, and length to suit their exact application needs, making these solutions highly adaptable.

FAQs of Mist Eliminator Demister:

Q: How does a Mist Eliminator Demister function in liquid-gas separation processes?

A: A Mist Eliminator Demister uses a high-porosity wire mesh to trap and remove fine liquid droplets from gas streams, ensuring efficient separation. The mesh structure promotes coalescence and drainage without significantly increasing pressure drop, enhancing process purity and equipment protection.Q: What surface treatments are available for the demister, and how do they improve its performance?

A: Our demisters come with surface treatments such as galvanization or polishing. Galvanization provides excellent corrosion resistance, especially in harsh chemical environments, while polished finishes improve cleanliness and reduce potential fouling, extending service life and maintaining efficiency.Q: When should a custom-sized demister be selected over standard rolls or sheets?

A: Custom-sized demisters are recommended when equipment specifications, process requirements, or installation conditions demand precise fitting and performance. They can be engineered to match unique aperture, wire gauge, and length needs, ensuring optimal mist separation in specialized applications.Q: Where are these demisters typically installed in industrial operations?

A: Mist Eliminator Demisters are commonly mounted in process vessels, scrubbers, absorption towers, and other equipment requiring liquid-gas separation. Their interlocking or panel-mounted design allows for secure installation and integration within existing plant systems.Q: What is the process for installing these mist eliminators?

A: Installation involves mounting the demister panels or interlocking rolls into designated frames or supports within the separation vessel. Instruction varies by design, but typically involves aligning and securing the mesh to maintain structural integrity and ensure effective mist removal.Q: What are the main benefits of using a steel wire mesh mist eliminator?

A: Steel wire mesh mist eliminators offer high durability, low pressure drop, and superior mist separation efficiency. Their resistance to corrosion and thermal degradation enables long service life, while customizable options cater to various process requirements, enhancing operational reliability and maintenance savings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Demister Pad Category

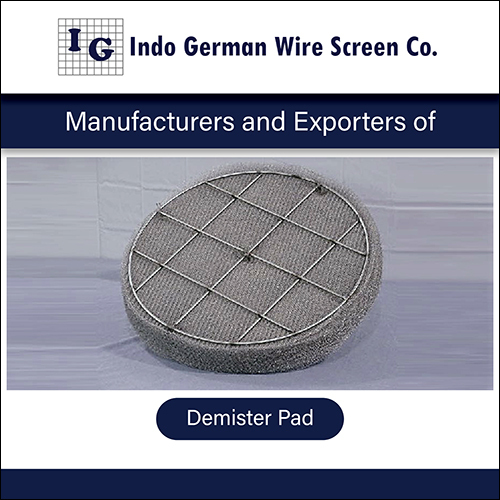

Demister Pad

Material : Stainless Steel

Surface Treatment : Polished

Product Type : Wire Mesh

Mesh Type : Steel Wire Mesh

Hole Shape : Other , Square

Length : Customizable as per requirement

Carbon Steel Demister Pad

Material : Steel

Surface Treatment : Polished

Product Type : Wire Mesh

Mesh Type : Iron Wire Mesh

Hole Shape : Square Hole

Length : Customized, as per order

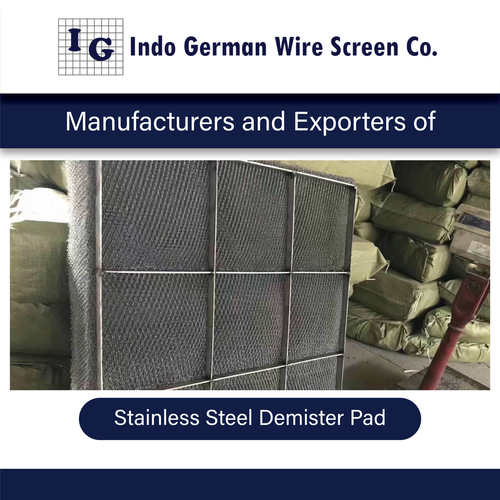

Stainless Steel Demister Pad

Material : Steel

Surface Treatment : Polished

Product Type : Wire Mesh

Mesh Type : Iron Wire Mesh

Hole Shape : Square Hole

Length : Up to 6000 mm or as specified

Knitted Wire Mesh Demister Pad

Material : Other, Carbon Steel, SS

Surface Treatment : Polished

Product Type : Wire Mesh

Mesh Type : Steel Wire Mesh

Hole Shape : Square Hole

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry