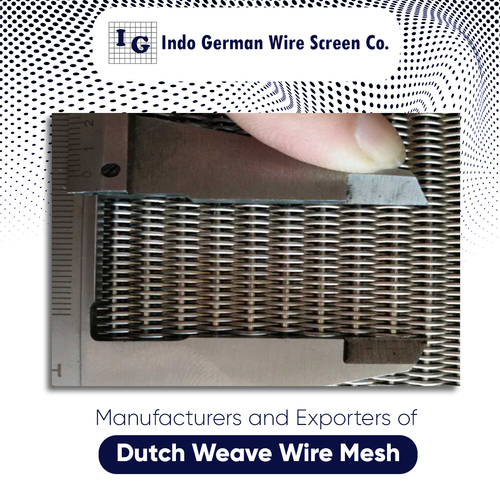

Dutch Weave Wire Mesh

Price 110 INR/ Square Foot

Dutch Weave Wire Mesh Specification

- Surface Treatment

- Polished

- Length

- 15 m, 30 m, or as required

- Hole Shape

- Rectangular

- Wire Gauge

- 32 - 52 SWG

- Aperture

- 0.05 mm - 0.35 mm

- Product Type

- Wire Mesh

- Mesh Type

- Other

- Mesh Style

- Plain Mesh

- Material

- Stainless Steel (SS304, SS316) or Brass

- Alloy

- SS304, SS316

- Application

- Filtration, Sieving, Chemical Processing, Pharma & Food Industry

- Dimensions

- 1 m x 15 m, 1.2 m x 30 m, or customized

- Wire Diameter

- 0.18 mm - 0.45 mm

- Weight

- Varies based on mesh size and material

- Color

- Silver

Dutch Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 10 Square Foots

- Supply Ability

- 10 Square Foots Per Day

- Delivery Time

- 1 Days

- Sample Available

- Yes

- Main Domestic Market

- All India

- Certifications

- Test Certification available at the time of dispatch.

About Dutch Weave Wire Mesh

Being a leader in the market, we are occupied in providing our customers a qualitative range of Dutch Weave Wire Mesh that is made by the use of coarse mesh. Our offered wire mesh is primarily in vacuum, fluid and pressure filtration of liquids and gases. This wire mesh is known for its greater mechanical stability, precise tolerances, resistant to corrosion, superior strength, fine finish and excellent thickness. Due to their high tensile strength, the offered Dutch Weave Wire Mesh is widely appreciated among our clients. Also, our renowned clients can avail these wire mesh at most affordable prices.

Material : Monel , Stainless steel 304,304L,316,316L,317,904L and etc.

Product Details

|

Type |

Electric Wire Mesh, Expanded Wire Mesh |

|

Material |

SS304,SS316 |

|

Mesh Size(per inch) |

0-10 |

Precision Filtration Performance

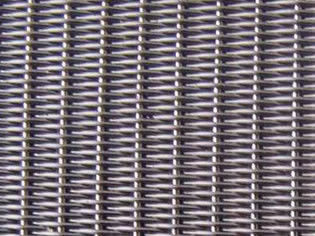

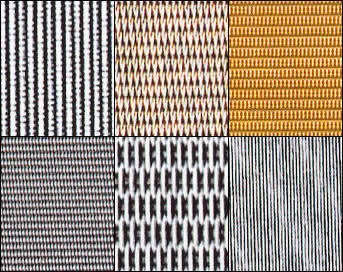

Dutch Weave Wire Mesh is renowned for its extremely fine openings and high mechanical strength, making it ideal for precise filtration applications. Its rectangular or irregular apertures allow consistent filtration of extremely small particles in demanding settings, such as gas and liquid systems, ensuring superior performance.

Sturdy and Versatile Materials

Manufactured using high-quality SS304, SS316, or brass, our Dutch weave wire mesh assures durability in corrosive and high-temperature environments. This versatility supports use across critical industries, from pharmaceuticals to oil & gas, by delivering extended service life and reliable operation.

Custom Sizing and Flexible Packing Options

Available in standard lengths of 15 m and 30 m or tailored to client requirements, Dutch Weave Wire Mesh offers flexible dimension choices. Packaged as rolls, in cartons, or wooden boxes, it meets the practical needs of manufacturers, exporters, and traders across India and beyond.

FAQs of Dutch Weave Wire Mesh:

Q: How is Dutch Weave Wire Mesh used in filtration applications?

A: Dutch Weave Wire Mesh is employed for precise filtration tasks in gas and liquid systems, including extruder screens, chemical processing, and the pharma & food industry. The fine openings effectively capture particulates, ensuring product purity and process efficiency.Q: What distinguishes Dutch Weave from other wire mesh types?

A: Dutch Weave features a unique weaving pattern with fine warp wires and coarser weft wires, resulting in extremely small and consistent opening sizes. This design provides superior mechanical strength, fine filtration, and resistance to clogging compared to standard meshes.Q: When should I choose stainless steel over brass material?

A: Stainless steel (SS304 or SS316) is advisable for applications requiring high corrosion resistance, strength, and temperature tolerance up to 800C, such as in chemical or oil & gas industries. Brass is suitable for less aggressive conditions where conductivity or specific chemical compatibility is needed.Q: Where can Dutch Weave Wire Mesh be installed?

A: This mesh can be integrated into filtration systems, sieves, extrusion machinery, and other industrial setups across sectors like oil & gas, pharmaceuticals, and food processing, wherever precise particle separation is essential.Q: What is the packing process for Dutch Weave Wire Mesh shipments?

A: Mesh can be supplied in rolls, then packed securely in cartons or durable wooden boxes. This ensures protection during storage and transit, safeguarding the meshs integrity until it is ready for installation.Q: What are the key benefits of using Dutch Weave Wire Mesh in critical industries?

A: Key benefits include high filtration precision, excellent corrosion and temperature resistance, robust tensile strength, and longevity even under severe operating conditions. These features contribute to the reliability and efficiency of various industrial filtration processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Different Shape Wire Mesh Category

Square Wire Mesh

Price Range 100.00 - 500.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Surface Treatment : Polished

Mesh Style : Other , Woven

Mesh Type : Aluminum Wire Mesh

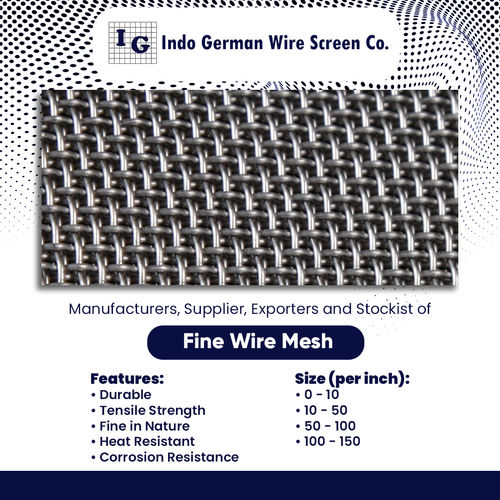

Fine Wire Mesh

Price 50 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Surface Treatment : Polished

Mesh Style : Woven Mesh

Mesh Type : Steel Wire Mesh

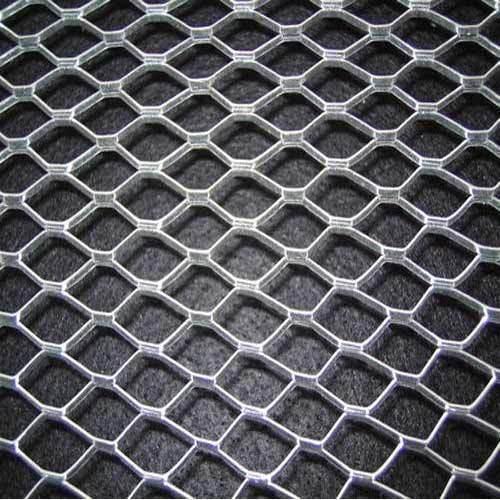

Diamond Wire Mesh

Price 16 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Surface Treatment : Polished

Mesh Style : Expanded Mesh

Mesh Type : Aluminum Wire Mesh

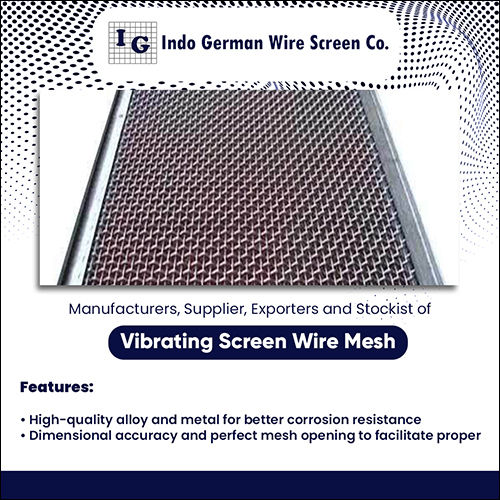

Vibrating Screen Wire Mesh

Price Range 2000.00 - 10000.00 INR / Piece

Minimum Order Quantity : 5 Pieces

Surface Treatment : Polished

Mesh Style : Chain Link Mesh

Mesh Type : Aluminum Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry