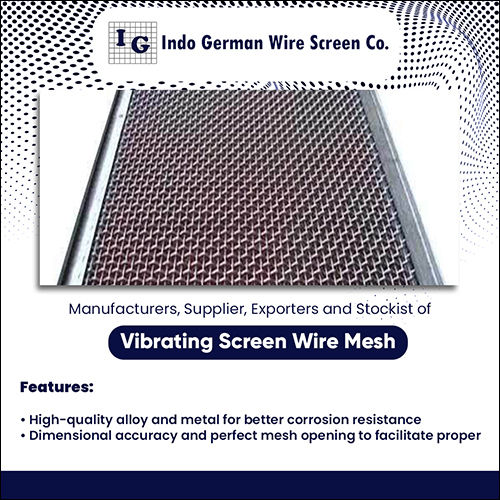

Vibrating Screen Wire Mesh

Vibrating Screen Wire Mesh Specification

- Surface Treatment

- Polished

- Product Type

- Wire Mesh

- Mesh Type

- Aluminum Wire Mesh

- Mesh Style

- Chain Link Mesh

- Material

- Aluminum

- Color

- Silver

Vibrating Screen Wire Mesh Trade Information

- Minimum Order Quantity

- 5 Pieces

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Packaging Details

- Carton Box

- Main Domestic Market

- All India

About Vibrating Screen Wire Mesh

We are based in Mumbai and have a great reputation in the market for supplying and manufacturing, best quality Vibrating Screen Wire Mesh. The offered mesh is manufactured using high-quality materials and the latest technology. For delivering a flawless mesh, it is tested on various quality parameters. It has a superior finish with high tensile strength and is accurate dimensionally. This Vibrating Screen Wire Mesh is used for different application in various industries. Some of the industries where it is used include chemical, coal, power plant, mining, and cement. It is capable of working under adverse conditions and is resistant to corrosion and chemicals.

Special Features of Vibrating Screen Wire Mesh:

- Featured with plain weaving surface and impact proof design

- Can resist abrasion and wear

- Notable for single intermediate crimp type or double crimp type design

- Good screening performance, made of low carbon steel wire

Product details

| Material Grade | SS 304, 316 |

| Material | Stainless Steel |

| Type | Woven Mesh |

| Hole Shape | Square, Circular |

Specification

| Material Grade | Stainless Steel |

| Usage | Industrial,Agricultural,Defence |

| Size | Customize |

Premium Aluminum Construction

Manufactured from high-quality aluminum, our vibrating screen wire mesh is built to last. The material choice ensures not only lightweight handling but also excellent resistance to rust and corrosion. This makes it suitable for environments where durability, ease of maintenance, and longevity are essential requirements.

Polished, Silver Finish for Versatility

Each mesh is polished to a smooth, silver brilliance, ensuring both visual appeal and practical benefits. The polished surface treatment adds a protective layer, making the mesh ideal for industries such as food processing, mining, and chemical production where hygiene and cleanability are critical.

FAQs of Vibrating Screen Wire Mesh:

Q: How is the Vibrating Screen Wire Mesh produced?

A: The mesh is manufactured using high-grade aluminum wire, woven into a chain link style. After forming the mesh, the surface undergoes polishing to achieve a smooth, silver finish that improves both aesthetics and corrosion resistance.Q: What are the main uses of the chain link style aluminum wire mesh?

A: This mesh is commonly used in screening, filtration, and separation processes across industries such as mining, construction, food processing, and chemical manufacturing. Its durability and resistance to corrosion make it ideal for demanding operational environments.Q: Where can this Vibrating Screen Wire Mesh be installed?

A: The mesh is versatile and can be installed in both indoor and outdoor settings, including vibrating screens, protective enclosures, and filtration systems in industrial facilities and construction sites.Q: When should you choose aluminum wire mesh over other materials?

A: Aluminum wire mesh is preferred when a lightweight, rust-resistant solution is needed without compromising strength. It excels in environments where exposure to moisture or corrosive elements is expected.Q: What is the benefit of the polished finish on the wire mesh?

A: The polished finish enhances the meshs overall corrosion resistance, makes cleaning easier, and adds to its visual appeal. This is especially beneficial in applications where hygiene or frequent maintenance is essential.Q: How does the chain link mesh style contribute to the meshs functionality?

A: The chain link style provides high tensile strength and stability, ensuring the mesh maintains its shape and performance even under continuous vibration or heavy loads. This makes it especially effective in screening and separation tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Different Shape Wire Mesh Category

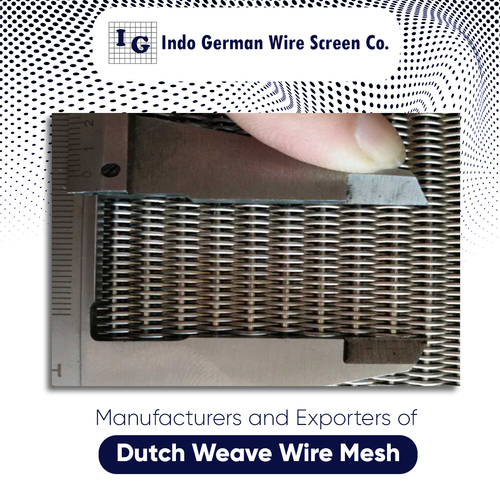

Dutch Weave Wire Mesh

Price 110 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Material : Other, Stainless Steel (SS304, SS316) or Brass

Surface Treatment : Polished

Color : Silver

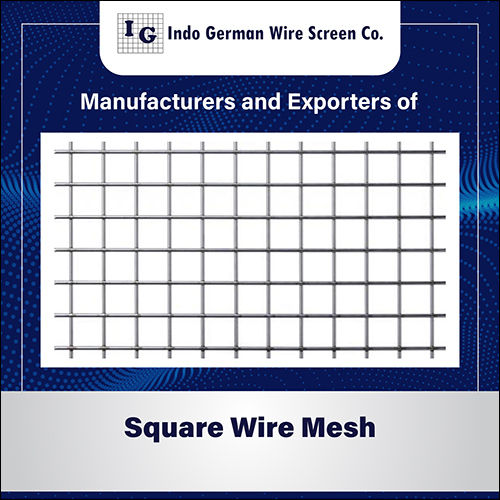

Square Wire Mesh

Price Range 100.00 - 500.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Material : Aluminum

Surface Treatment : Polished

Color : Silver

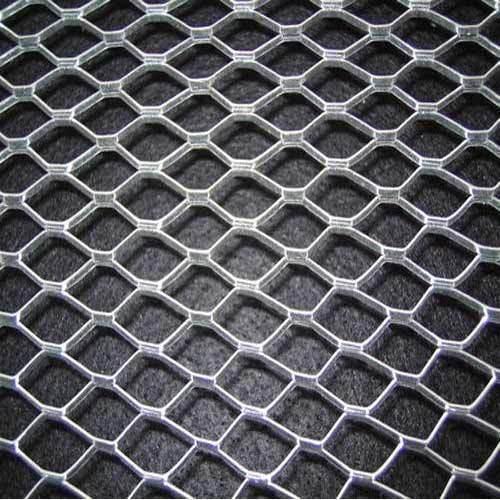

Diamond Wire Mesh

Price 16 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Material : Aluminum

Surface Treatment : Polished

Color : Silver

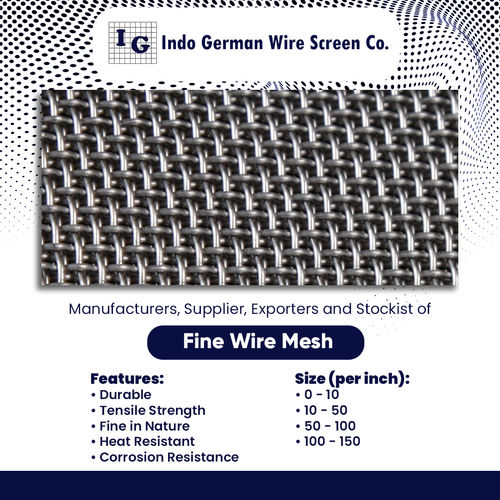

Fine Wire Mesh

Price 50 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Material : Steel

Surface Treatment : Polished

Color : Silver

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry