Dutch Weave Wire Mesh conveyor belt

Price 50 INR/ Unit

Dutch Weave Wire Mesh conveyor belt Specification

- Surface Treatment

- Coated

- Hole Shape

- Rectangular/Oblong (Specialty of Dutch Weave)

- Wire Gauge

- 24 to 10 SWG

- Aperture

- As per specification, typically ranges from 0.1 mm to 8 mm

- Length

- As per requirement, typically up to 30 meters per roll

- Product Type

- Wire Mesh

- Mesh Type

- Dutch Weave

- Mesh Style

- Plain Mesh

- Material

- Metal Alloys

- Alloy

- Stainless Steel 304, 316, or custom alloys

- Application

- Other

- Dimensions

- Custom sizes available, standard width up to 2 meters

- Wire Diameter

- 0.2 mm to 1 mm

- Weight

- Varies by specifications, typically 215 kg/m

- Color

- Silver

- Tensile Strength

- High tensile strength for industrial conveying applications

- Belt Edge Type

- Welded, Ladder, or Chain Type Edges

- Maximum Width Available

- Up to 2 meters

- Corrosion Resistance

- Excellent, especially with stainless steel alloys

- Standard Roll Length

- 10 m, 15 m, or as per requirement

- Permeability

- Low, suitable for fine filtration and conveying small products

- Finish

- Smooth, burr-free finish for uninterrupted conveying

- Belt Thickness

- Typically ranges from 1 mm to 5 mm

- Typical Uses

- Food processing, chemical conveyor, filtration systems, pharmaceuticals, and industrial ovens

- Operating Temperature

- -100°C to 600°C (depending on alloy)

- Weave Type

- Dutch Plain Weave or Dutch Twill Weave

Dutch Weave Wire Mesh conveyor belt Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Dutch Weave Wire Mesh conveyor belt

Conveyor beltsare normally friction driven and are popular for conveying a wide range of products, mainly those that are small or need a lot of support.Conveyor beltsare multipurpose conveyor belts having excellent strength-to-weight ratio, flat surface, good flexibility, and minimal maintenance.InDutch wire cloth,the main feature is the warp and weft wire diameter thereby forming a firm and strong cloth producing a cloth with no readily visible apertures. ThisDutch weave wire meshis strong and stable, easy to clean and with a good flow rate suitable for high-pressure liquid/solid separation.We offer an exclusive range ofDutch Weave Wire Mesh Conveyor Beltsat unmatched quality and market leading prices.

Optimized for Industrial Demands

Designed with high tensile strength and excellent corrosion resistance, these conveyor belts perform reliably in tough industrial environments. Their smooth, burr-free finish ensures uninterrupted product conveying and minimal maintenance. Whether used in filtration systems or demanding ovens, they maintain efficiency under extreme conditions.

Versatile Edge Options

Choose from welded, ladder, or chain type edges to suit your specific conveying application. Each edge type offers unique benefits for stability, flexibility, and lifespan, allowing you to tailor your conveyor belt to the demands of food processing, chemical transfer, or pharmaceutical movement.

Customization and Specifications

Our Dutch Weave Wire Mesh belts are available in thicknesses from 1 mm to 5 mm, standard widths up to 2 meters, and roll lengths up to 30 meters. With aperture sizes ranging from 0.1 mm to 8 mm and wire diameters from 0.2 mm to 1 mm, each belt is crafted to meet specialized needs for filtration, product sorting, or high-temperature conveying processes.

FAQs of Dutch Weave Wire Mesh conveyor belt:

Q: How is Dutch Weave Wire Mesh advantageous for industrial conveyors?

A: Dutch Weave Wire Mesh offers high tensile strength, low permeability, and excellent corrosion resistance, making it highly suitable for conveying fine products and filtration in demanding industries. Its robust structure ensures reliable performance and extended belt life.Q: What are the available edge types for these conveyor belts and when should each be used?

A: Edge options include welded, ladder, and chain type. Welded edges provide superior strength for heavy loads, ladder edges offer flexibility for food and pharmaceutical conveying, while chain edges are ideal for precise tracking in long-running applications.Q: Where are Dutch Weave Wire Mesh conveyor belts typically utilized?

A: These belts are commonly used in food processing plants, chemical factories, filtration systems, pharmaceutical production, and industrial ovens due to their durability and suitability for handling fine products under varying temperatures.Q: What benefits does the low permeability of Dutch Weave Wire Mesh provide?

A: Low permeability is essential for fine filtration and prevents product loss during conveying. This makes Dutch Weave ideal for transporting small articles, filtering liquids, or separating particulates in chemical and pharmaceutical industries.Q: How can I specify the size and material for my application requirements?

A: Belts can be ordered with custom dimensions, wire gauges, and alloys. Standard widths go up to 2 meters and lengths up to 30 meters. Stainless steel 304, 316, or other alloys are available, depending on operating temperature and corrosion resistance needs.Q: What is the process for manufacturing Dutch Weave Wire Mesh conveyor belts in India?

A: Manufacturers, exporters, and suppliers in India use high-quality metal alloys and precision weaving techniques to produce belts with smooth finishes, accurate apertures (from 0.1 mm up to 8 mm), and customized specifications for various industrial applications.Q: What finishes and surface treatments can be expected from these conveyor belts?

A: Each belt features a smooth, burr-free finish with optional coatings to enhance corrosion resistance and ensure hygienic conveying, especially important for food and pharmaceutical uses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh conveyor belt Weave types Category

Compound Balance Weave Conveyer Belt

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Plain Mesh

Material : Metal Alloys

Mesh Type : Other , Compound Balance Weave

Product Type : Wire Mesh

Inter crimp Wire Mesh conveyor belt

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Other , Crimped

Material : Other, Stainless Steel / Mild Steel / Galvanized Iron

Mesh Type : Other , Woven / Interlocked

Product Type : Other, Inter Crimp Wire Mesh Conveyor Belt

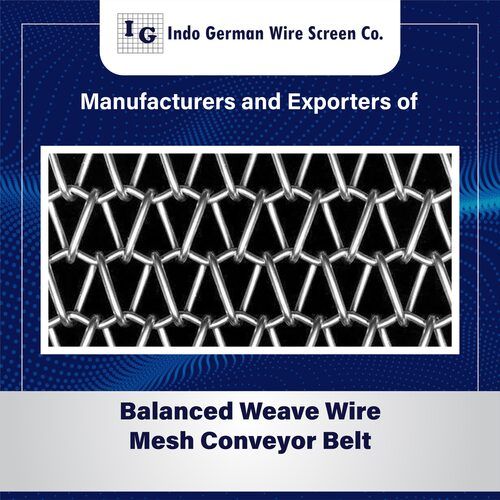

Balanced Weave Conveyer Belt

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Other , Woven

Material : Other, Stainless Steel / Mild Steel

Mesh Type : Other , Balanced Weave

Product Type : Other, Balanced Weave Conveyor Belt

Plain crimp Wire Mesh conveyor belt

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Plain Mesh

Material : Steel

Mesh Type : Steel Wire Mesh

Product Type : Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry