Inter crimp Wire Mesh conveyor belt

Price 50 INR/ Unit

Inter crimp Wire Mesh conveyor belt Specification

- Wire Gauge

- 18 to 22 SWG

- Length

- Custom Lengths Available

- Surface Treatment

- Galvanized / Polished / Uncoated

- Aperture

- 6 mm to 25 mm

- Hole Shape

- Square

- Product Type

- Inter Crimp Wire Mesh Conveyor Belt

- Mesh Type

- Woven / Interlocked

- Mesh Style

- Crimped

- Material

- Stainless Steel / Mild Steel / Galvanized Iron

- Alloy

- Stainless Steel 304/316 or Customized

- Application

- Conveyor Systems, Material Handling, Industrial Ovens, Food Processing

- Dimensions

- As per Requirement

- Wire Diameter

- 0.7 mm to 1.2 mm

- Weight

- Varies With Size and Material

- Color

- Silver / Metallic Grey

- Corrosion Resistance

- Excellent (Stainless Steel Option)

- Operating Temperature

- Up to 800°C (Depending on Material)

- Open Area

- 45% - 70%

- Standard Roll Width

- 300 mm to 2000 mm

- Usage Environment

- Indoor/Outdoor, Wet/Dry Processes

- Packing Type

- Rolls or Cut Pieces

- Edge Construction

- Welded or Knuckled Edge

- Tensile Strength

- High, Suitable for Heavy Loads

About Inter crimp Wire Mesh conveyor belt

Conveyor belts are normally friction driven and are popular for conveying a wide range of products, mainly those that are small or need a lot of support. Conveyor belts are multipurpose conveyor belts having excellent strength-to-weight ratio, flat surface, good flexibility, and minimal maintenance.Inter crimped Wire mesh is made of all kinds of alloy and metals and also a very popular woven wire mesh with an extra crimp in both warp and fill wire is known as inter crimped wire mesh. Both the warp and Shute/ weft wires are crimped with extra crimps or corrugations between the points of intersection. This technique is usually required when weaving large openings with fine wires. We offer an exclusive range of Inter Crimp Wire Mesh Conveyor Belts at unmatched quality and market leading prices.

Robust Edge Construction for Durability

Our Inter Crimp Wire Mesh Conveyor Belts are designed with either welded or knuckled edges, ensuring enhanced durability under continuous use. The robust edge design prevents fraying or deformation, making them ideal for heavy-duty applications in material handling and industrial environments.

Versatile Performance in Extreme Conditions

Engineered to perform reliably at temperatures up to 800C, these wire mesh belts are suitable for various industrial processes, including food processing and oven operations. Their versatility extends to both indoor and outdoor environments, accommodating wet and dry process requirements.

FAQs of Inter crimp Wire Mesh conveyor belt:

Q: How is the edge construction of the Inter Crimp Wire Mesh Conveyor Belt beneficial?

A: The belt features welded or knuckled edges, providing improved structural integrity that prevents edge wear and fraying. This makes the belt ideal for heavy load applications and prolongs its service life, especially in demanding industrial settings.Q: What environments and processes can this conveyor belt be used in?

A: These conveyor belts are suitable for both indoor and outdoor use, and perform well in wet or dry processes. They are commonly utilized in conveyor systems, industrial ovens, food processing, and material handling where robust, corrosion-resistant materials are essential.Q: When should I consider opting for stainless steel material for the conveyor belt?

A: Stainless steel is recommended when exceptional corrosion resistance is required, particularly in wet, acidic, or food-grade environments. It also enables operation at higher temperatures (up to 800C), making it ideal for industrial oven and heat treatment processes.Q: Where can the standard roll widths and lengths be customized?

A: Standard roll widths range from 300 mm to 2000 mm, and lengths can be tailored to specific requirements. Custom sizes and configurations are available from the manufacturer or supplier to meet the distinct needs of your industrial application.Q: What is the process for choosing the right mesh type, hole shape, and surface treatment?

A: Selection depends on your operational needs: mesh style (interlocked, crimped, woven), hole shape (square or other), and surface treatment (galvanized, polished, uncoated) should be matched to desired durability, corrosion resistance, and aperture requirements. Consult the exporter or supplier for guidance based on your industry application.Q: How does using this wire mesh conveyor belt benefit my material handling system?

A: With high tensile strength, customizable open areas, and excellent corrosion resistance, these conveyor belts enhance operational efficiency, reduce downtime, and support safe movement of heavy loads. Their adaptability to various environments ensures consistent, reliable performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh conveyor belt Weave types Category

Dutch Weave Wire Mesh conveyor belt

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Material : Metal Alloys

Mesh Type : Other , Dutch Weave

Product Type : Wire Mesh

Twill Weave Wire Mesh conveyor belt

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Material : Metal Alloys

Mesh Type : Other , Twill Weave Mesh

Product Type : Wire Mesh

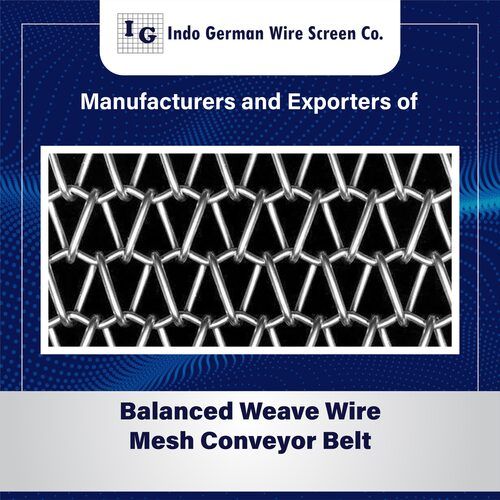

Balanced Weave Conveyer Belt

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Metallic Silver

Material : Other, Stainless Steel / Mild Steel

Mesh Type : Other , Balanced Weave

Product Type : Other, Balanced Weave Conveyor Belt

Plain crimp Wire Mesh conveyor belt

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Material : Steel

Mesh Type : Steel Wire Mesh

Product Type : Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry