Flat Top Wire Mesh Screen

Price 50 INR/ Unit

Flat Top Wire Mesh Screen Specification

- Length

- Up to 8 meters

- Surface Treatment

- Galvanized, Painted, or Plain

- Hole Shape

- Rectangular or Square

- Aperture

- Customizable from 2mm to 50mm

- Wire Gauge

- Available in sizes from 1mm to 12mm as per requirement

- Product Type

- Flat Top Wire Mesh Screen

- Mesh Type

- Woven

- Mesh Style

- Flat Top

- Material

- High Carbon Steel, Stainless Steel

- Alloy

- Stainless Steel (304, 316), Mild Steel

- Application

- Mining, Quarrying, Aggregate Screening, Industrial Filtration

- Dimensions

- Custom sizes as per client specifications

- Wire Diameter

- From 2mm to 12mm

- Weight

- Depends on mesh size and dimensions, typically 480 kg/m

- Color

- Silver/Grey typical, can be customized

- Life Span

- 510 years depending on application and maintenance

- Temperature Resistance

- Up to 500C

- Load Capacity

- High tensile strength for heavy-duty applications

- Usage

- Used in vibrating screens, scalping, dewatering, and sizing operations

- Open Area Percentage

- Ranges between 30%78% depending on mesh size

- Packing Type

- Packed in rolls or flat panels with wooden crates or pallets

- Maintenance

- Easy to clean and replace; low maintenance

- Corrosion Resistance

- Excellent, especially in Stainless Steel variants

- Manufacturing Method

- Woven and flattened using precision machinery

- Customization

- Aperture, wire diameter, dimensions, and finish can be tailored as per demand

- Edge Type

- Hooked, Flat, and Welded edges available

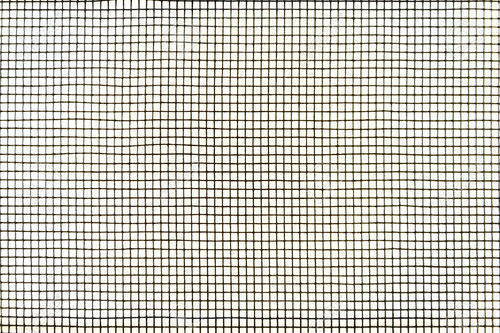

About Flat Top Wire Mesh Screen

Flat Top Wire Mesh is a welded wire mesh panel precisely manufactured by welding thin and thick diameter wires. Flat Top Wire Mesh Plain weave is the most frequently used weave in which each warp wire crosses interchangeably above and below each weft wire. Warp wires and weft wires usually have the same diameter.

Flat Top Wire Mesh Screens are available in different sizes and wide-range can be customized to fit your exact specifications in order to meet your specific application requirements. We offer an exclusive range of Flat Top Wire Mesh Screens at unmatched quality and market leading prices.

Versatile Edge Types for Secure Fit

Choose from hooked, flat, or welded edges to match your machinery and application requirements. Each edge type ensures a snug installation in vibrating screens and other equipment, enhancing operational stability and longevity while minimizing downtime. The selection caters to diverse installation conditions and screening processes.

Exceptional Durability and Resistance

Flat Top Wire Mesh Screens are engineered for demanding environments, boasting high tensile strength and impressive resilience against corrosion. With the ability to operate in temperatures up to 500C, these screens are a preferred choice for heavy-duty and high-temperature applications in mining, aggregates, and industrial filtration.

Comprehensive Customization Options

Tailor your wire mesh specifications with customizable aperture sizes, wire diameters (from 1mm to 12mm), hole shapes, dimensions, and finishes. Options include galvanized, painted, or plain surfaces to deliver optimal performance and aesthetic appeal, ensuring your screen matches specific process needs and operational conditions.

FAQs of Flat Top Wire Mesh Screen:

Q: How are Flat Top Wire Mesh Screens installed, and what edge types are available for secure fitting?

A: Flat Top Wire Mesh Screens can be installed using hooked, flat, or welded edges, allowing compatibility with various equipment, including vibrating screens and scalping systems. The chosen edge type ensures a secure and stable fit, minimizing risk of movement during operation.Q: What materials are used in these screens, and which offer the best corrosion resistance?

A: These screens are manufactured from high carbon steel, stainless steel (grades 304 and 316), and mild steel. Stainless steel variants provide excellent corrosion resistance, making them ideal for applications requiring long-term durability, especially in harsh environmental conditions.Q: When should I opt for high tensile wire mesh for my application?

A: High tensile wire mesh is recommended for heavy-duty usage such as mining, quarrying, and aggregate screening, where strong materials are needed to withstand significant loads, abrasion, and frequent cleaning processes.Q: Where are these wire mesh screens typically used?

A: Flat Top Wire Mesh Screens are widely used in vibrating screens, scalping operations, dewatering processes, sizing, and industrial filtration across mining, quarrying, and aggregate industries, ensuring efficient material sorting and filtering.Q: How does the manufacturing process ensure precision and long life span?

A: The screens are woven and flattened using high-precision machinery that maintains consistent aperture, wire spacing, and mesh flatness, resulting in reliable performance and resistance to wear, with a life span of five to ten years, depending on application and maintenance practices.Q: What are the packing options for delivery, and how is product safety ensured during transit?

A: Flat Top Wire Mesh Screens are packed either in rolls or flat panels and secured in sturdy wooden crates or pallets. This packaging method ensures safe handling, prevents damage, and facilitates easy transportation, whether for export or local supply.Q: What benefits does customization provide for specific screening applications?

A: Customization offers flexibility in mesh size (aperture from 2mm to 50mm), wire diameter, panel dimensions, and surface treatments, ensuring the screen perfectly matches the operational demands, enhances screening efficiency, and provides an optimal lifespan tailored to the application.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh Screen Category

Wire Mesh Filter Screen

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Product Type : Other, Wire Mesh Filter Screen

Material : Stainless Steel

Mesh Type : Other , Fine Mesh

Stainless Steel Screen

Minimum Order Quantity : 50 Feet, ,

Color : Silver

Product Type : Wire Mesh

Material : Stainless Steel

Mesh Type : Steel Wire Mesh

Shale Shaker Screen

Price 15000 INR / Piece

Color : Sliver

Product Type : Wire Mesh

Material : Stainless Steel

Mesh Type : Steel Wire Mesh

Wire Screen

Color : Silver / Black / Green

Product Type : Other, Wire Screen

Material : Other, Mild Steel / Stainless Steel / GI

Mesh Type : Other , Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry