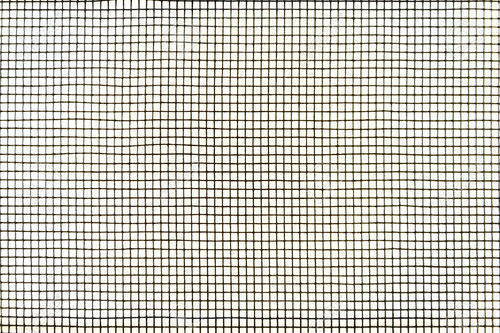

Stainless Steel Screen

Stainless Steel Screen Specification

- Surface Treatment

- Painted, Coated, , Welding, Sandblasting, Anodized, Oxidized, Mill Finish, Powder Coating, Polished, Plated, Anti-oil Cleaning

- Product Type

- Wire Mesh

- Mesh Type

- Steel Wire Mesh

- Material

- Stainless Steel

- Alloy

- ss

- Color

- Silver

Stainless Steel Screen Trade Information

- Minimum Order Quantity

- 50 Feet, ,

- FOB Port

- mumbai

- Payment Terms

- Letter of Credit (L/C), Paypal, Cash in Advance (CID), Cheque

- Supply Ability

- 10000 Feet, , Per Week

- Delivery Time

- 7 Days

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Stainless Steel Screen

We are one of the leading manufacturer and supplier of Stainless steel screen.We obligated to meet the quality standards as per the customer demand.

Product details

|

Country of Origin |

Made in India |

|

Usage |

Industrial |

|

Usage/Application |

Industrial |

|

Material |

Stainless Steel |

|

Brand |

Indo German Wire Screen Co. |

|

Color |

Silver |

|

Technique |

Perforated |

Versatile Surface Treatments for Enhanced Performance

Our stainless steel screens undergo a wide array of surface treatments such as powder coating, polishing, plating, sandblasting, and anodizing. These processes not only improve corrosion resistance and aesthetics but also enhance durability and operational lifespan. The diverse treatments accommodate different environmental and functional requirements, ensuring the screens fit a variety of industries and performance specifications.

Global Reach with Local Expertise

As a manufacturer, exporter, supplier, and trader based in India, we ensure consistent product quality and timely delivery worldwide. Our team leverages in-depth industry knowledge to meet precise specifications for stainless steel wire mesh, serving clients in construction, chemical processing, filtration, and numerous other sectors. We pride ourselves on exceptional service and support, making us a reliable partner for all your wire mesh needs.

FAQs of Stainless Steel Screen:

Q: How are stainless steel screens treated and finished for enhanced durability and performance?

A: Stainless steel screens are treated using processes like painting, coating, welding, sandblasting, anodizing, oxidizing, mill finish, powder coating, polishing, plating, and anti-oil cleaning. Each surface treatment is chosen to enhance specific properties such as corrosion resistance, wear resistance, and aesthetic appeal, making the screens suitable for demanding industrial applications.Q: What is the main benefit of using stainless steel wire mesh with surface treatments?

A: The primary benefit is improved corrosion resistance and longevity, even in harsh environments. Surface treatments also add to the screens strength, cleanliness, and appearance, ensuring reliable performance in filtration, separation, and protective uses across various industries.Q: Where can stainless steel screens with these treatments be used?

A: These treated stainless steel screens are widely used in construction, chemical processing, oil refineries, food production, filtration systems, and security frameworks. Their adaptability and robust properties make them suitable for both indoor and outdoor applications.Q: When is it advisable to choose a particular surface treatment for stainless steel mesh?

A: The choice depends on your application requirements. For example, powder coating is recommended for enhanced corrosion resistance, while polishing offers a high-gloss finish. Sandblasting is used when a matte texture is needed, and anodizing or plating can add additional layers of protection in corrosive environments.Q: What is the process for manufacturing stainless steel wire mesh screens?

A: The process begins with selecting high-quality stainless steel alloy (ss), which is then fashioned into mesh type steel wire mesh. The screens undergo advanced treatments such as welding, coating, polishing, and cleaning, ensuring a precise finish and optimal performance for the intended applications.Q: How do exporters and suppliers in India ensure the quality of stainless steel screens?

A: Indian manufacturers and exporters follow stringent quality control practices, from raw material selection to final surface treatment. Each batch is thoroughly tested for durability, strength, and finish to meet international standards, ensuring reliable performance and customer satisfaction.Q: What are the advantages of using anti-oil cleaning for stainless steel screens?

A: Anti-oil cleaning removes grease, oil, and other contaminants from the wire mesh, resulting in a cleaner and more effective screen. It also helps in prolonging the service life, maintaining optimal filtration efficiency, and ensuring the product meets strict industry hygiene standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh Screen Category

Flat Top Wire Mesh Screen

Price 50 INR / Unit

Product Type : Other, Flat Top Wire Mesh Screen

Mesh Type : Other , Woven

Color : Silver/Grey typical, can be customized

Hole Shape : Other , Rectangular or Square

Material : Other, High Carbon Steel, Stainless Steel

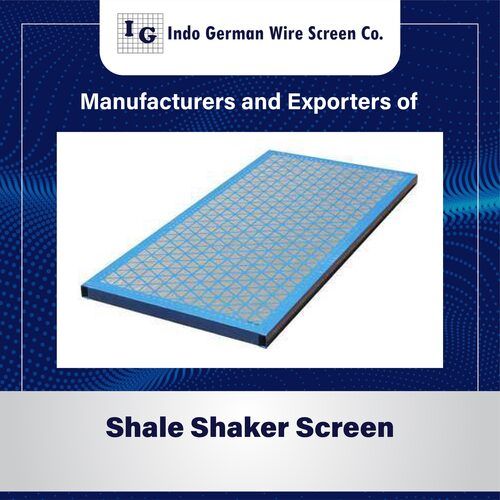

Shale Shaker Screen

Price 15000 INR / Piece

Product Type : Wire Mesh

Mesh Type : Steel Wire Mesh

Color : Sliver

Hole Shape : Other , Square

Material : Stainless Steel

Wire Screen

Product Type : Other, Wire Screen

Mesh Type : Other , Wire Mesh

Color : Silver / Black / Green

Hole Shape : Other , Square

Material : Other, Mild Steel / Stainless Steel / GI

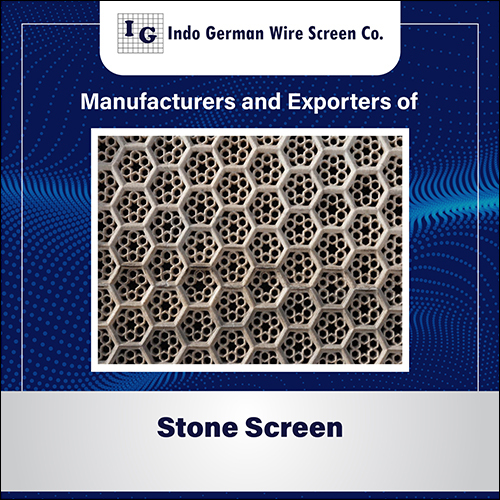

Stone Screen

Product Type : Wire Mesh

Mesh Type : Steel Wire Mesh

Color : Silver

Hole Shape : Square Hole

Material : Other, Metal

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry