Inconel Circular Wire Mesh

Price 50 INR/ Unit

Inconel Circular Wire Mesh Specification

- Hole Shape

- Square

- Aperture

- 0.025 mm 2 mm

- Surface Treatment

- Coated

- Wire Gauge

- 10 to 50 SWG

- Length

- up to 30 meters (customizable)

- Product Type

- Wire Mesh

- Mesh Type

- Inconel Wire Mesh

- Mesh Style

- Woven, Circular

- Material

- Inconel (Nickel-Chromium Alloy)

- Alloy

- Inconel 600, 625, 800, 825 (customizable)

- Application

- Other

- Dimensions

- Standard: Circular, diameter customizable (as per requirement)

- Wire Diameter

- 0.025 mm 2 mm

- Weight

- Depends on mesh size and diameter

- Color

- Silver

- Standard Roll Width

- up to 4 ft (customizable)

- Temperature Resistance

- Withstands up to 1100C

- Edge Type

- Smooth, burr-free circular cut

- Tensile Strength

- High

- Corrosion Resistance

- Excellent against acids and alkalis

- Packing Type

- Rolls or cut circles, bubble wrap, corrugated box

- Opening Size

- 0.025 mm 2 mm

- Finish

- Bright or Matte as required

Inconel Circular Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Inconel Circular Wire Mesh

Inconel is a mixture of nickel-chromium alloy and aluminium or molybdenum is added into Inconel as per requirement and grade. Inconel are useful in a wide range of industrial applications as they are heat resistant, corrosion resistant, and they tend to provide great productivity and service even after prolonged use.Circular Wire cloth plain weaveis the most frequently used weave in which each warp wire crosses interchangeably above and below each weft wire. Warp wires and weft wires usually have the same diameter.We offer an exclusive range ofInconel Circular Wire Meshat unmatched quality and market leading prices.

Superior Performance in Extreme Conditions

Inconel Circular Wire Mesh excels under aggressive chemical and thermal environments, ensuring reliable operation even at temperatures up to 1100C. Its robust corrosion resistance effectively shields against acids and alkalis, making it suitable for chemical processing, petrochemical industries, and high-temperature filtration tasks. The mesh maintains structural integrity and consistent filtration across diverse applications.

Customizable Dimensions and Packing Options

Available in various wire gauges (10 to 50 SWG) and opening sizes (0.025 mm to 2 mm), users can select standard roll widths up to 4 ft or request customized lengths and diameters. Finishes in bright or matte, plus secure packing methodsrolls, cut circles, bubble wrap, and corrugated boxesguarantee safe transport and storage tailored to project needs. Mesh style and alloy selection are fully customization-friendly.

FAQs of Inconel Circular Wire Mesh:

Q: How is Inconel Circular Wire Mesh manufactured to ensure burr-free edges?

A: The wire mesh is precision-cut using advanced processes to produce smooth, burr-free circular edges, minimizing the risk of contamination and ensuring safety during installation and use.Q: What are the typical industrial applications for Inconel Circular Wire Mesh?

A: This mesh is commonly used in filtration, separation, and screening in chemical processing, petrochemical plants, aerospace, and high-temperature manufacturing areas due to its durability and resistance properties.Q: When should I choose an Inconel mesh over other materials?

A: Select Inconel mesh when high tensile strength, extreme temperature resistance (up to 1100C), and superior corrosion resistance against both acids and alkalis are critical to your applications success.Q: Where can I source custom-sized Inconel Wire Mesh in India?

A: You can obtain customizable Inconel Circular Wire Mesh directly from specialized exporters, manufacturers, suppliers, and traders throughout India, many of whom offer tailored sizing and alloy options to match your requirements.Q: What is the process for customizing mesh dimensions and finishes?

A: Customers provide specific diameter, wire gauge, and aperture details, as well as preferred finishes (bright or matte). The manufacturer then produces and packages the mesh according to these exact specifications.Q: How is the mesh packed to ensure it reaches the destination undamaged?

A: The mesh is delivered in rolls or cut circles, securely wrapped in bubble wrap and packed within corrugated boxes, providing robust protection against physical damage and environmental exposure during transit.Q: What benefits does the coated surface treatment provide?

A: The coated surface further enhances the meshs resistance to corrosion, prolongs its functional lifespan, and contributes to maintaining mesh brightness or matte finish as required.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Circular Wire Mesh Category

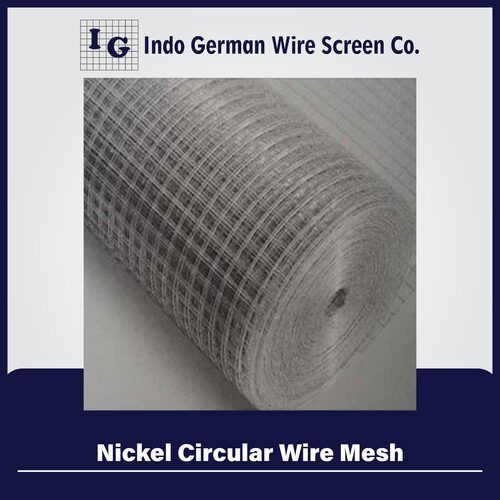

Nickel Circular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Application : Other, Filtration, Separators, Chemical Processing, Battery Electrode, Catalysis

Surface Treatment : Coated

Mesh Type : Other , Woven / Crimped

Iron Circular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Application : Other

Surface Treatment : Coated

Mesh Type : Iron Wire Mesh

Steel Circular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Application : Other

Surface Treatment : Coated

Mesh Type : Steel Wire Mesh

Bronze Circular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Application : Other

Surface Treatment : Coated

Mesh Type : Other , Bronze Wire Mesh(

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry