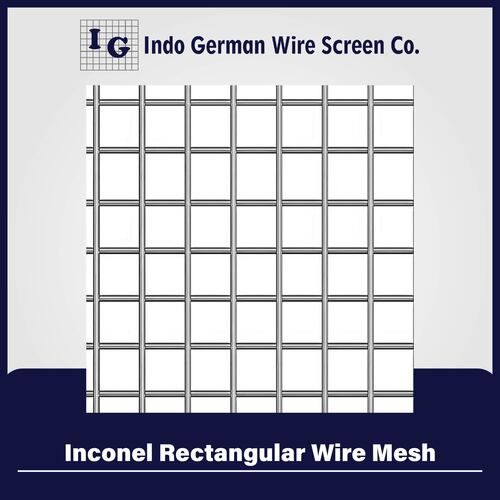

Inconel Rectangular Wire Mesh

Price 50 INR/ Unit

Inconel Rectangular Wire Mesh Specification

- Surface Treatment

- Coated

- Product Type

- Wire Mesh

- Mesh Type

- Inconel Wire Mesh(

- Mesh Style

- Plain Mesh

- Material

- Inconel

- Color

- Silver

Inconel Rectangular Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Inconel Rectangular Wire Mesh

Inconel is a mixture of nickel-chromium alloy and aluminium or molybdenum is added in to Inconel as per requirement and grade. Inconel are useful in wide range of industrial applications as they are heat resistant, corrosion resistant, and they tend to provide great productivity and service even after prolonged use.Inconel Rectangular Wire cloth plain weaveis the most frequently used weave in which each warp wire crosses interchangeably above and below each weft wire. Warp wires and weft wires usually have the same diameter.We offer an exclusive range ofInconel Rectangular Wire Meshat unmatched quality and market leading prices.

Engineered for Extreme Environments

Inconel Rectangular Wire Mesh is purpose-built for applications where ordinary materials simply cannot endure. Its exceptional resistance to both environmental and chemical corrosion makes it a preferred choice in sectors such as petrochemical, refining, aerospace, and chemical processing. With its coated surface and robust design, users can rely on this mesh under intense pressures and temperatures without compromising structural integrity.

Quality Manufacturing by Indian Experts

Produced by reputable exporters, manufacturers, suppliers, and traders from India, Inconel Wire Mesh meets rigorous quality standards. Advanced manufacturing techniques ensure precision in mesh openings and uniformity, while the protective coating enhances lifespan. Customers benefit from reliable delivery and comprehensive support, making the procurement process seamless for both local and international buyers.

FAQs of Inconel Rectangular Wire Mesh:

Q: How is Inconel Rectangular Wire Mesh manufactured?

A: Inconel Rectangular Wire Mesh is produced by weaving Inconel alloy wires into a plain mesh style that forms rectangular openings. The process is precise to maintain dimensional accuracy and is followed by surface coating for enhanced durability.Q: What are the main benefits of using Inconel Wire Mesh?

A: The primary benefits include superior resistance to heat and corrosion, long service life, and consistent filtration performance. Its robustness makes it ideal for demanding industrial applications where conventional materials may fail.Q: Where is Inconel Wire Mesh commonly used?

A: This wire mesh is widely used in chemical processing, petrochemical facilities, oil refineries, aerospace, and thermal industries, particularly where exposure to harsh chemicals and high temperatures is frequent.Q: What is the purpose of the surface coating on the wire mesh?

A: The surface treatment, which results in a silver finish, provides additional resistance to oxidation and extends the lifespan of the wire mesh in corrosive and high-temperature environments.Q: When should I choose Inconel Wire Mesh over other materials?

A: Opt for Inconel Wire Mesh when your application involves extreme conditions, such as high temperatures or aggressive chemical exposure, where standard stainless steel or other alloys may degrade quickly.Q: How can I procure Inconel Rectangular Wire Mesh in India?

A: You can obtain this mesh from established exporters, manufacturers, suppliers, and traders based in India, who offer a wide range of sizes and mesh specifications tailored to various industrial needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rectangular Wire Mesh Category

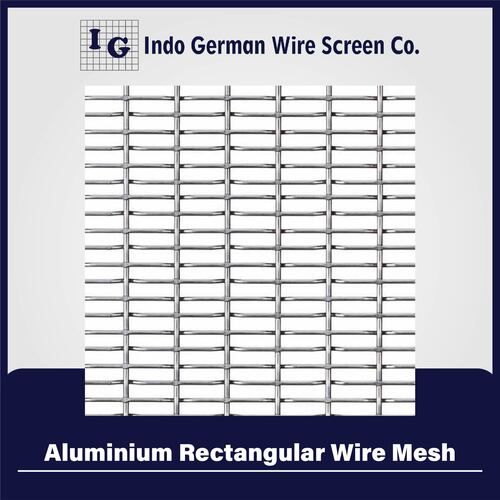

Aluminium Rectangular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Type : Aluminum Wire Mesh

Material : Aluminum

Product Type : Wire Mesh

Color : Silver

Stainless Steel Rectangular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Type : Steel Wire Mesh

Material : Stainless Steel

Product Type : Wire Mesh

Color : Silver

Nickel Rectangular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Type : Other

Material : Other

Product Type : Wire Mesh

Color : Silver

Iron Rectangular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Type : Iron Wire Mesh

Material : Iron

Product Type : Wire Mesh

Color : Silver

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry