Inconel Wire Mesh 625

Inconel Wire Mesh 625 Specification

- Hole Shape

- Square Hole

- Aperture

- 1.2 mm

- Wire Gauge

- 14 SWG

- Length

- 30 m

- Surface Treatment

- Annealed

- Product Type

- Wire Mesh

- Mesh Type

- Steel Wire Mesh

- Mesh Style

- Woven Mesh

- Material

- Steel

- Alloy

- Inconel 625

- Application

- Aerospace, chemical processing, marine, and nuclear industries

- Dimensions

- 1 m x 30 m

- Wire Diameter

- 2.03 mm

- Weight

- Approx. 26 kg/roll

- Color

- Metallic Grey

- Corrosion Resistance

- Excellent against pitting and crevice corrosion

- Standard

- ASTM B443

- Melting Point

- 1350C 1400C

- Edge Type

- Cut Edge or Selvage Edge

- Weave Type

- Plain Weave

- Tensile Strength

- 870 MPa (min)

- Packaging

- Roll, wooden box, or as per requirement

- Operating Temperature

- Up to 1000C

Inconel Wire Mesh 625 Trade Information

- Minimum Order Quantity

- 50 Square Foots

- Supply Ability

- 10 Square Foots Per Day

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Inconel Wire Mesh 625

To cater the variegated demands of our prestigious clients, we are highly occupied in providing a wide assortment of Incoloy Wire Mesh. It is a heat resistant alloy, which can resist heat easily. Our offered wire mesh is known for its resist corrosion, good strength, easy to install, require no maintenance and tensile strength qualities. Due to their rust proof finish and easy installation, our offered wire mesh is highly acknowledged among our precious customers. In addition to this, our clients can avail this Incoloy Wire Mesh at industry leading prices.

Product details

|

Material |

Inconel 625 |

|

Brand |

Indo German |

|

Color |

Silver |

|

Material Grade |

Inconel 625 |

|

Weave Type |

wire mesh |

|

Usage/Application |

Industrial |

Precision Engineering for Demanding Applications

Designed to meet the severe requirements of industries like aerospace, marine, and nuclear, Inconel Wire Mesh 625 offers outstanding performance under extreme conditions. Its plain weave design ensures uniformity and durability, while the advanced alloy composition provides resistance to aggressive chemical environments and high temperatures.

Advanced Material Properties

This wire mesh is produced from Inconel 625 alloy, ensuring a minimum tensile strength of 870 MPa and a melting point of up to 1400C. The annealed metallic grey finish enhances stability and longevity, offering remarkable defense against pitting and crevice corrosion. The mesh is fabricated to precise specifications for reliable protection and separation.

Flexible Packaging and Custom Solutions

As a leading exporter, manufacturer, supplier, and trader in India, we offer flexible packaging options, including rolls and wooden boxes, or as specified. Choose between cut edge or selvage edge finishes to match installation needs. Our commitment to quality ensures the best solutions for industry challenges.

FAQs of Inconel Wire Mesh 625:

Q: How is Inconel Wire Mesh 625 typically used in various industries?

A: Inconel Wire Mesh 625 is utilized in aerospace, chemical processing, marine, and nuclear sectors primarily for filtration, reinforcement, and specialized separation tasks. Its excellent corrosion resistance and high-temperature endurance make it suitable for demanding environments where reliability is critical.Q: What process is involved in the manufacturing of this wire mesh?

A: The manufacturing process involves weaving Inconel 625 alloy wires into a plain weave pattern, followed by annealing to relieve stresses and enhance durability. The mesh is then finished to required sizes with options for cut or selvage edges, fully complying with ASTM B443 standards.Q: When should I choose Inconel 625 mesh over other materials?

A: Select Inconel 625 wire mesh when your application faces highly corrosive substances, elevated temperatures up to 1000C, or demanding mechanical stress. Its resistance to pitting and crevice corrosion provides superior longevity compared to regular stainless steel meshes in such conditions.Q: Where can this mesh be installed safely?

A: This mesh is designed for safe installation in corrosive and high-temperature environments found in chemical plants, aerospace components, marine structures, and nuclear facilities. Its robust design and versatility enable it to function effectively even under harsh industrial conditions.Q: What are the benefits of its plain weave and square hole structure?

A: The plain weave and square hole arrangement deliver consistent mesh openings, allowing for precise filtration and particulate separation. This structure also imparts mechanical strength, ensuring reliable performance and ease of cleaning during maintenance.Q: How is the mesh packaged and supplied to customers?

A: We offer packaging options such as tightly wound rolls, wooden boxes, or custom requests according to client needs. Each unit, typically measuring 1 m x 30 m and weighing about 26 kg per roll, is carefully packed to prevent damage during transportation.Q: What surface treatment does the mesh undergo and how does it improve performance?

A: Each wire mesh is annealed, a heat treatment process that improves ductility, stress resistance, and corrosion performance. This ensures the finished mesh maintains its structural integrity and resists chemical attack in aggressive environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh By Material Category

Bronze Wire Mesh

Price 100 INR / Square Foot

Minimum Order Quantity : 10 Units, ,

Product Type : Wire Mesh

Mesh Type : Iron Wire Mesh

Application : Other

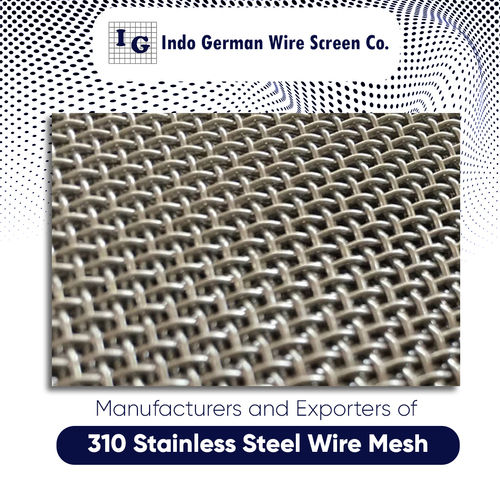

310 Stainless Steel Wire Mesh

Price Range 150.00 - 750.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Product Type : Wire Mesh

Mesh Type : Steel Wire Mesh

Application : Other, Filtration, screening, sieving, architectural, chemical processing, high temperature environments

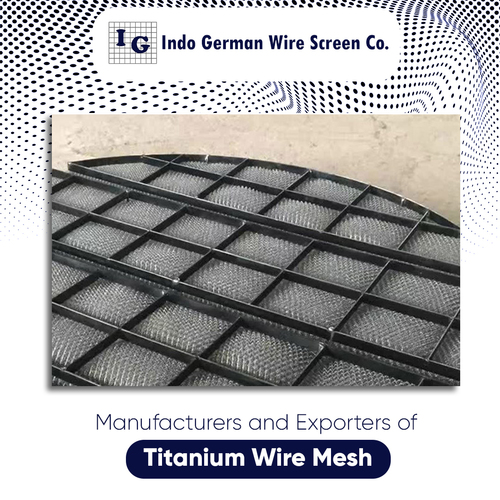

Titanium Wire Mesh

Price Range 2000.00 - 3000.00 INR

Minimum Order Quantity : 10 Square Foots

Product Type : Wire Mesh

Mesh Type : Steel Wire Mesh

Application : Other, Filtration, Chemical Processing, Marine, Aerospace, Medical, Industrial Separation

Inconel 600 Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Mesh Type : Other , Crimped / Plain

Application : Other, High temperature filtration, Chemical processing, Aerospace, Power generation

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry