Inconel 600 Wire Mesh

Price 50 INR/ Unit

MOQ : 1 Unit

Inconel 600 Wire Mesh Specification

- Aperture

- 0.5 mm to 10 mm

- Hole Shape

- Square or Rectangular

- Length

- 10 meters to 50 meters

- Surface Treatment

- Annealed, Pickled

- Wire Gauge

- 10 to 30 SWG

- Product Type

- Wire Mesh

- Mesh Type

- Crimped / Plain

- Mesh Style

- Woven / Welded

- Material

- Inconel 600

- Alloy

- Nickel-Chromium Alloy (Inconel 600)

- Application

- High temperature filtration, Chemical processing, Aerospace, Power generation

- Dimensions

- Custom sizes available (Standard: 1 m x 30 m roll)

- Wire Diameter

- 0.3 mm to 2.5 mm

- Weight

- Varies with mesh and wire diameter

- Color

- Silver Grey

- Corrosion Resistance

- Excellent in acidic and alkaline environments

- Density

- 8.47 g/cm³

- Standard

- ASTM B166

- Temperature Resistance

- Up to 1150°C

- Tensile Strength

- 550 MPa minimum

- Melting Point

- 1370°C - 1425°C

- Edge Type

- Cut Edge / Selvage Edge

- Packing

- Rolls, Wooden cases, or as required

- Weaving Type

- Plain Dutch Weave, Twill Weave, Crimped

About Inconel 600 Wire Mesh

Indo German Wire Screen Co. is one of the leading manufacturer, supplier, and exporter and stockist of industrial Wire Mesh, Wire Cloth, Wire Screen, Wire Netting Knitted Wire Mesh, Welded Wire Mesh, Expanded Mesh, Woven Wire Mesh, Fine Wire Mesh, Galvanized Wire Mesh, Epoxy Coated Wire Mesh, Wire Mesh Filter, Demister Pad, Vibrating Screen Wire Mesh, Wire Mesh, Conveyer belt, Sifter Sieves, Perforated Sheets, and many more products in India manufactured. These high-quality products are manufactured at our premises using quality tested raw materials and components according to industry quality standards.Superior High-Temperature Performance

Inconel 600 Wire Mesh delivers stable performance under extreme temperatures, tolerating conditions up to 1150C. Its high melting point (1370C1425C) makes it indispensable for applications involving intense heat, such as aerospace components, heat shields, or filtration in power plants.

Excellent Corrosion Resistance

This wire mesh stands out for its remarkable resistance to both acidic and alkaline environments, ensuring durability in challenging chemical processes. The alloys intrinsic strength (minimum 550 MPa tensile strength) and non-reactivity safeguard against structural degradation, extending operational lifespan.

Versatile Mesh Design and Customization

Available in multiple weave typesincluding Plain Dutch, Twill, and Crimpedthe mesh is tailored for precise filtration or screening needs. Options in aperture size (0.5 mm to 10 mm), wire diameter (0.3 mm to 2.5 mm), and dimensions make it adaptable to a wide variety of industrial setups, with packaging and delivery options to suit every project.

FAQs of Inconel 600 Wire Mesh:

Q: How is Inconel 600 Wire Mesh manufactured?

A: Inconel 600 Wire Mesh is produced by weaving or welding drawn wires of Nickel-Chromium Alloy (Inconel 600) following ASTM B166 standards. Different weave typessuch as Plain Dutch, Twill, or Crimpedare used based on filtration requirements, and the mesh can be supplied with either cut or selvage edges.Q: What applications are ideal for Inconel 600 Wire Mesh?

A: This mesh is suitable for high temperature filtration, chemical processing, aerospace components, and power generation. Its superior resistance to corrosion and heat makes it invaluable in processes that demand stability under harsh or fluctuating conditions.Q: When should I consider using Inconel 600 over other mesh materials?

A: Consider Inconel 600 Wire Mesh when operations involve prolonged exposure to extreme temperatures (up to 1150C) or corrosive environmentsespecially where both acidity and alkalinity challenge conventional materials. It is preferred where stainless steel or lesser alloys may fail.Q: Where can Inconel 600 Wire Mesh be purchased?

A: The mesh can be sourced from specialized manufacturers, exporters, and suppliers, particularly in India. Suppliers offer customized sizing, packaging, and finishing options based on your projects needs.Q: What processes are used for the surface treatment of Inconel 600 Wire Mesh?

A: Surface treatments available for the mesh include annealing and pickling. These processes improve mechanical properties and remove contaminants, resulting in enhanced performance and a characteristic silver-grey finish.Q: How does the mesh benefit high-temperature and corrosive operations?

A: Inconel 600 offers a combination of high tensile strength, corrosion resistance, and thermal stability, ensuring operational reliability and longer service life for equipment in demanding environments. This reduces maintenance intervals and replacement costs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Wire Mesh By Material Category

309 stainless steel wire mesh

Price 1000-100000.00 INR / Foot

Minimum Order Quantity : 50 Feet

Color : Silver

Mesh Type : Other , Wire Mesh

Product Type : Wire Mesh

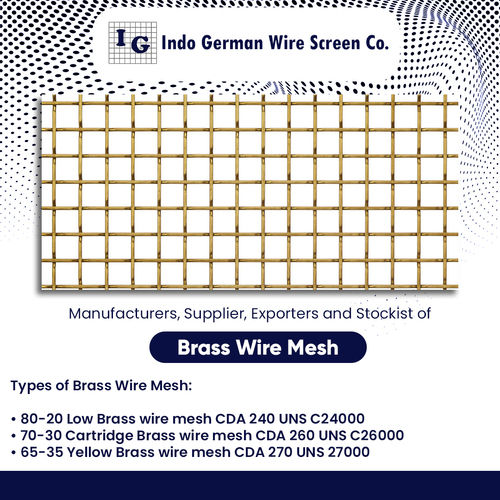

Bronze Wire Mesh

Price 100 INR / Square Foot

Minimum Order Quantity : 10 Units, ,

Color : Golden

Mesh Type : Iron Wire Mesh

Product Type : Wire Mesh

Monel 400 Wire Mesh

Price Range 500.00 - 2000.00 INR

Minimum Order Quantity : 10 Square Foots

Color : Sliver

Mesh Type : Steel Wire Mesh

Product Type : Wire Mesh

Inconel 601 Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Metallic grey

Mesh Type : Other , Fine / Coarse

Product Type : Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry