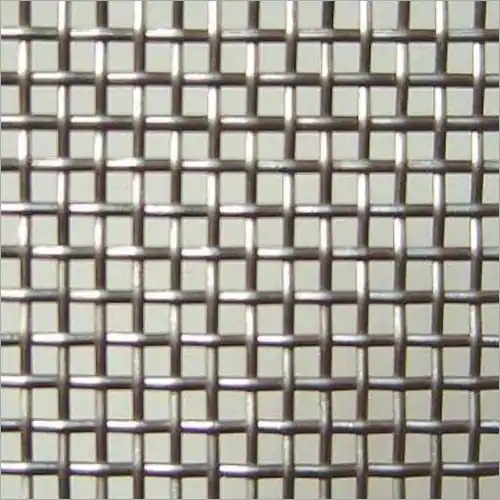

Metal Wire Mesh

Metal Wire Mesh Specification

- Length

- 30 Meter

- Surface Treatment

- Polished

- Wire Gauge

- 16 Gauge

- Aperture

- 3 mm

- Hole Shape

- Rectangular

- Product Type

- Wire Mesh

- Mesh Type

- Other

- Mesh Style

- Plate Mesh

- Material

- Stainless Steel

- Alloy

- 304 Grade

- Application

- Filtration, Fencing, Construction

- Dimensions

- 1220 mm x 2440 mm

- Wire Diameter

- 1.6 mm

- Weight

- Approx. 32 kg per sheet

- Color

- Siver

Metal Wire Mesh Trade Information

- Minimum Order Quantity

- 100 Square Foots

- Supply Ability

- 10 Square Foots Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Carton Box

- Main Domestic Market

- All India

About Metal Wire Mesh

Metal Wire Mesh offered by us is highly appreciated for having superior tensile strength, corrosion resistance, and deformation stability. It is widely utilized for construction, architectural, & filtering applications. This mesh is also admired for having the accurate dimensional & structural configuration. It is said to be perfect for both outdoor & indoor use for having superior weather resistance. This Metal Wire Mesh has flat top hence is ideal for manufacturing of conveyor belts that are suitable for high & low-temperature applications. Prior to dispatch, it is tested on rigorous parameters so as to ensure superior performance.

Special Features :

- It is made of 304 grade stainless steel and has plain weaving pattern.

- It shows high yielding strength under high tension condition.

- Wear proof, static electricity protection capacity and precise diameter

- Completely protected against acid and alkali

Robust and Versatile Construction

Made from 304 grade stainless steel, this metal wire mesh is engineered for strength and durability. Its high tensile properties and corrosion resistance ensure longevity even in demanding environments. The meshs rectangular apertures make it versatile for diverse applications, from filtration to fencing and construction projects.

Adaptable Design and Ease of Use

Offering both roll and sheet packing options, this mesh can be implemented in various setups as per user needs. Its standard dimensions and manageable weight make transportation, storage, and installation convenient for industrial and commercial users alike.

Ideal for High-Temperature and Harsh Environments

With the capacity to endure operating temperatures up to 800C and excellent resistance against corrosion, this mesh stands out for use in high-stress areas, such as chemical facilities and food processing plants. Its polished surface further aids in easy maintenance and cleaning.

FAQs of Metal Wire Mesh:

Q: How is this metal wire mesh typically installed for filtration and fencing applications?

A: Installation depends on your application. For fencing, the mesh can be mounted onto supporting frames or posts, using fixing clips or welding. For filtration, it may be integrated within filter housings or set as screening elements. Its plain edge finish allows for seamless attachment in both scenarios.Q: What are the key benefits of choosing 304 grade stainless steel for this mesh?

A: 304 grade stainless steel provides a balance of superior tensile strength and resistance to rust, corrosion, and high temperatures. This makes the mesh highly durable and reliable for use in environments exposed to chemicals, moisture, or intense heat.Q: Where can this polished plate mesh be used effectively?

A: The mesh is well-suited for a variety of industrial and commercial spaces. Common uses include filtration systems, security fencing, protective barriers, and structural reinforcements in construction projects. Its polished surface enhances longevity in food grade and cleanroom environments.Q: What is the manufacturing process for this type of wire mesh?

A: The mesh is manufactured by weaving or welding 16 gauge stainless steel wires into a plate mesh style with a 3 mm rectangular aperture. The welded or woven mesh then undergoes polishing to enhance surface quality and corrosion resistance before being cut to specified dimensions and packed.Q: When should I select rolls versus sheets for my project?

A: Choose rolls if you require long, continuous lengths for large-scale installations or custom cutting on-site. Sheets are preferable for fixed panels, smaller projects, or when predetermined sizes streamline assembly and reduce waste.Q: How does the 57% open area benefit industrial usage?

A: A 57% open area provides an optimal balance between airflow or liquid passage and physical strength. This makes the mesh particularly beneficial in filtration and ventilation applications, where high throughput and minimal clogging are critical.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh Category

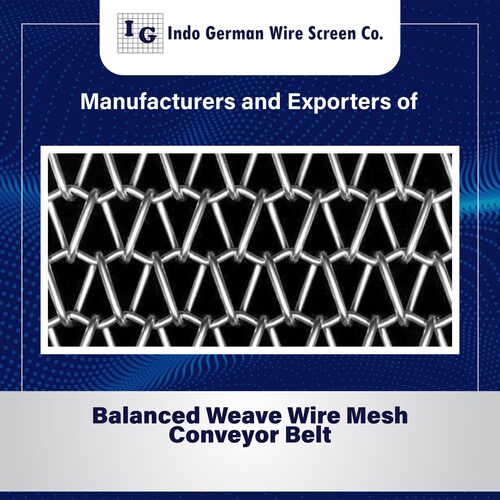

Balanced Weave Wire Mesh Conveyor Belt

Price 1000-100000.00 INR / Foot

Minimum Order Quantity : 50 Feet, ,

Mesh Type : Steel Wire Mesh

Product Type : Wire Mesh

Material : Steel

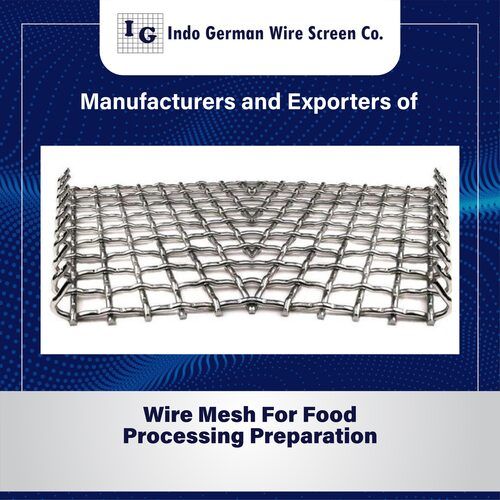

Wire Mesh For Food Processing and Preparation

Price 1000-100000.00 INR / Foot

Minimum Order Quantity : 50 Feet

Mesh Type : Steel Wire Mesh

Product Type : Wire Mesh

Material : Steel

Wire Mesh Filter Cloth

Price Range 400.00 - 4000.00 INR / Meter

Minimum Order Quantity : 5 Meters

Mesh Type : Iron Wire Mesh

Product Type : Wire Cloth

Material : Stainless Steel

Galvanized Barbed Iron Wire

Price Range 58.00 - 75.00 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Mesh Type : Steel Wire Mesh

Product Type : Wire Mesh

Material : Stainless Steel

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry