Lock Crimped Woven Wire Mesh

Price 50 INR/ Unit

Lock Crimped Woven Wire Mesh Specification

- Hole Shape

- Square Hole

- Surface Treatment

- Coated

- Product Type

- Wire Mesh

- Mesh Style

- Crimped Wire Mesh

- Material

- Metal Alloys

- Application

- Other

- Color

- Silver

Lock Crimped Woven Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Lock Crimped Woven Wire Mesh

Lock Crimped Woven Wire Meshis technically a wire mesh panel accurately manufactured by, woven to size in the same technique cloth is woven, manufactured on a loom.Lock Crimped Woven Wire Meshis a refinement of the intermediate crimped wire mesh. It can lock the wire at its position by pressing at each side of the raised wire.It is particularly useful because it works perfectly with hot or cold liquids, is extremely chemical resistant, and can be easily cleaned.Lock Crimped Woven Wire Meshis normally woven on looms, like looms that are normally used to weave cloth. In this case, wires, not yarn, are used to produce wire mesh.Durable Metal Alloy Construction

Our lock crimped woven wire mesh is manufactured from high-grade metal alloys, producing a strong and long-lasting solution suitable for demanding environments. The robust nature of the material ensures consistent performance, even under heavy loads, making it a preferred choice in industries like mining, construction, and quarrying.

Advanced Surface Coating for Longevity

Each wire mesh undergoes a specialized surface treatment involving durable coatings, providing outstanding protection against corrosion and wear. The silver finish further enhances resistance to environmental factors, ensuring low maintenance and extended service life for your installations.

FAQs of Lock Crimped Woven Wire Mesh:

Q: How is lock crimped woven wire mesh manufactured?

A: Lock crimped woven wire mesh is produced by interweaving metal alloy wires that are pre-crimped and then locked in place at each intersection. This process ensures a sturdy and uniform mesh structure with square holes, offering excellent stability and strength.Q: What is the purpose of the surface coating on the mesh?

A: The surface coating enhances the meshs resistance to corrosion, abrasion, and environmental wear. It maintains the silver color and protects the metal alloys, extending the products operational life and ensuring sustained aesthetic appeal.Q: When should lock crimped woven wire mesh be used?

A: This type of mesh is ideal for applications where strength and stability are critical, such as in mining screens, architectural design, fencing, filtration, and separation processes. Use it when robust, long-lasting performance is necessary.Q: Where can the lock crimped wire mesh be installed?

A: The mesh is suitable for various environments including construction sites, quarries, screening plants, and industrial facilities. Its versatility also makes it appropriate for architectural and decorative applications, both indoors and outdoors.Q: What is the process for ordering mesh from your company in India?

A: Clients can contact us directly as an exporter, manufacturer, supplier, and trader. We offer product customization, technical guidance, and efficient nationwide or international delivery ensuring timely and tailored solutions.Q: How can users benefit from using crimped wire mesh with a square hole design?

A: The square hole design provides uniform opening sizes for efficient screening, filtration, or sifting. Together with the lock crimp structure, it delivers reliability, reduces product loss, and supports increased throughput in industrial operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Woven Wire Mesh types Category

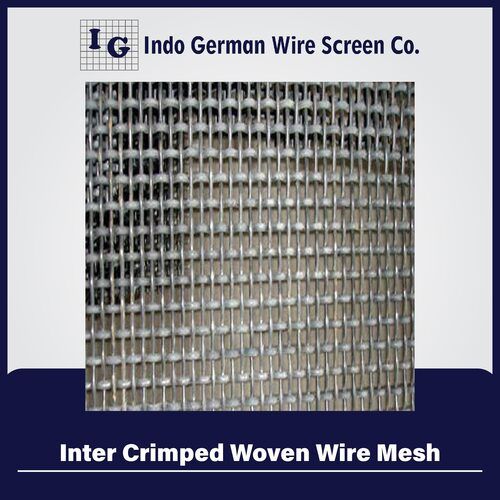

Inter Crimped Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Material : Metal Alloys

Application : Other

Mesh Style : Crimped Wire Mesh

Five Shed Twill Weave Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Material : Metal Alloys

Application : Other

Mesh Style : Woven Mesh

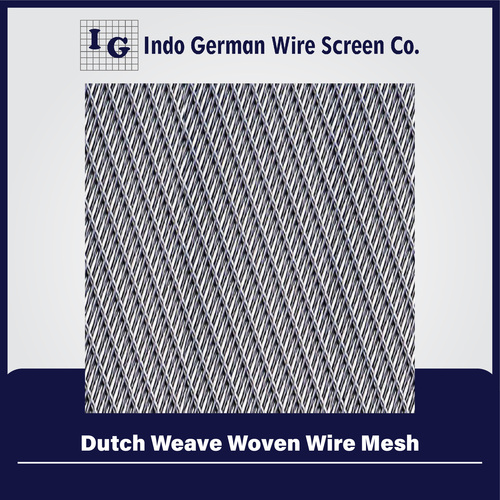

Dutch Weave Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Material : Other, Stainless Steel, Brass, Copper

Application : Other, Filtration, Sieving, Industrial, Chemical Processing

Mesh Style : Other , Dutch Weave

Reverse Dutch Weave Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver / Metallic

Material : Other, Stainless Steel (SS304, SS316), Mild Steel, Brass

Application : Other, Filtration, Sieving, Extruder screens, Chemical and Food industry

Mesh Style : Woven Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry