Flat Top Woven Wire Mesh

Price 50 INR/ Unit

Flat Top Woven Wire Mesh Specification

- Wire Gauge

- 16G to 2G

- Surface Treatment

- Coated

- Hole Shape

- Rectangular / Square

- Length

- Up to 30 meters

- Aperture

- 2mm to 60mm

- Product Type

- Wire Mesh

- Mesh Type

- Flat Top Mesh

- Mesh Style

- Woven Mesh

- Material

- Metal Alloys

- Alloy

- Available in Stainless Steel, Mild Steel, Galvanized Steel

- Application

- Other

- Dimensions

- Customizable as per requirement

- Wire Diameter

- 1.6mm to 6mm

- Weight

- Variable depending on specification

- Color

- Silver

- Open Area Percentage

- Up to 80%

- Usable Temperature Range

- Up to 550°C

- Corrosion Resistance

- Excellent - suitable for outdoor environments

- Edge Type

- Plain or Clamped

- Tensile Strength

- High strength suitable for industrial use

- Packing Type

- Wrapped in waterproof paper, palletized

- Typical Uses

- Screening, Fencing, Filtration, Industrial Sieving

- Roll or Sheet Supply

- Available in rolls or cut sheets

- Weaving Method

- Flat Top (one-side flat, other-side crimped)

Flat Top Woven Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Flat Top Woven Wire Mesh

Versatile Mesh for Industrial Demands

Flat Top Woven Wire Mesh combines high strength, excellent corrosion resistance, and customizable dimensions for versatile industrial use. Its one flat side and one crimped side design provide enhanced surface stability, making it a reliable choice for screening, filtering, fencing, and more. Available in stainless steel, mild steel, or galvanized steel, this mesh offers flexibility in both material selection and configuration.

Customizable Configuration and Supply Options

Our mesh is available with edge typesplain or clampedto suit different installation needs. Customers can choose from rolls up to 30 meters or request cut sheets as per project requirements. With aperture sizes from 2mm to 60mm, and wire diameters ranging from 1.6mm to 6mm, you can specify exactly what you need for efficient application.

Exceptional Durability and Resistance

A key advantage of our Flat Top Woven Wire Mesh is its resilience. Manufactured to withstand temperatures up to 550C and harsh outdoor environments, it is treated for superior corrosion resistance and stability. The mesh undergoes surface coating and meticulous packaging, ensuring it arrives in excellent condition, ready for industrial use.

FAQs of Flat Top Woven Wire Mesh:

Q: How is Flat Top Woven Wire Mesh manufactured for industrial strength?

A: Flat Top Woven Wire Mesh is produced using high-quality metal alloys with a distinctive weaving process, in which one side remains flat while the other is crimped. This structure, along with precise control over wire diameter (1.6mm6mm) and mesh configuration, grants it outstanding tensile strength and dimensional stability.Q: What edge types are available, and how do I select the right one?

A: This mesh is offered with either plain or clamped edges. Plain edges are suited for simple installations, while clamped edges provide additional grip and security, especially beneficial for heavy-duty or high-tension applications. Selection depends on installation method and site conditions.Q: When should I use Flat Top Woven Wire Mesh for my project?

A: Use Flat Top Woven Wire Mesh when you require high strength, large open area (up to 80%), corrosion resistance, and the ability to withstand temperatures up to 550C. It excels in applications like screening, filtration, fencing, and industrial sieving across sectors such as mining, processing, or construction.Q: Where can Flat Top Woven Wire Mesh be installed effectively?

A: It can be effectively installed in both indoor and outdoor environments due to its robust corrosion resistance and weather tolerance. Typical sites include factories, processing plants, construction sites, and perimeter fencing areas, where durability and longevity are crucial.Q: What are the available customization options for size and material?

A: Customers can specify mesh length (up to 30 meters), width, aperture (2mm60mm), wire gauge (16G2G), edge type, and the alloy (stainless steel, mild steel, or galvanized steel). This ensures precise fit for your unique operational requirements.Q: How is the mesh delivered and protected during transport?

A: Flat Top Woven Wire Mesh is wrapped in waterproof paper and palletized to guard against moisture, impact, and damage in transit. Surface coatings further enhance protection, so you receive the mesh ready for installation.Q: What are the benefits of choosing Flat Top Woven Wire Mesh for screening and filtration?

A: This mesh style provides a flat working surface for even material distribution, high throughput, and minimal clogging. Its strength and corrosion resistance translate to reduced maintenance frequency and long service life, delivering excellent value for industrial screening and filtration.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Woven Wire Mesh types Category

Double Crimped Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Product Type : Wire Mesh

Mesh Style : Crimped Wire Mesh

Material : Metal Alloys

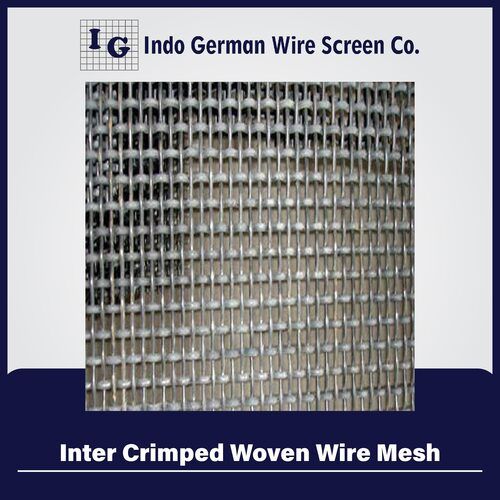

Inter Crimped Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Product Type : Wire Mesh

Mesh Style : Crimped Wire Mesh

Material : Metal Alloys

Reverse Dutch Weave Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver / Metallic

Product Type : Other, Reverse Dutch Weave Woven Wire Mesh

Mesh Style : Woven Mesh

Material : Other, Stainless Steel (SS304, SS316), Mild Steel, Brass

Pre Crimped Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Product Type : Wire Mesh

Mesh Style : Crimped Wire Mesh

Material : Metal Alloys

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry