Mesh For Pharma Industry

Price 1000.00-100000.00 INR/ Foot

Mesh For Pharma Industry Specification

- Surface Treatment

- Polished

- Hole Shape

- Square Hole

- Product Type

- Wire Mesh

- Mesh Type

- Steel Wire Mesh

- Material

- Steel

- Color

- Silver

Mesh For Pharma Industry Trade Information

- Minimum Order Quantity

- 50 Feet, ,

- FOB Port

- mumbai

- Payment Terms

- Letter of Credit (L/C), Paypal, Cash Advance (CA), Cash in Advance (CID), Cheque

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Mesh For Pharma Industry

We are one of the leading manufacturers, supplier, stockist, dealer and exporter of Wire mesh for Pharma industry in Mumbai, India.

Product details

|

Application |

Industrial |

|

Packaging Type |

Standard Type |

|

Country of Origin |

Made in India |

|

Material Grade |

304,316 |

|

Size |

Custmize |

Premium Steel Wire Mesh for Pharma Applications

Steel wire mesh with a polished silver surface and square holes is engineered specifically for pharmaceutical processes requiring sanitary conditions and reliability. Its robust construction ensures durability, while the precise design facilitates efficient filtration and separation tasks. Manufactured in India, our mesh adheres to international standards for purity and strength, supporting pharma operations in research, production, and packaging.

FAQs of Mesh For Pharma Industry:

Q: How is the steel wire mesh used in the pharmaceutical industry?

A: Steel wire mesh is utilized in the pharmaceutical sector for filtration, sieving, separation, and material handling processes. Its square holes and polished surface provide optimal flow characteristics and minimize contamination, making it suitable for processing powders, granules, and liquids.Q: What benefits does a polished steel surface offer for pharma applications?

A: A polished steel surface enhances corrosion resistance and facilitates easy cleaning, which is critical in pharmaceutical environments where hygiene is mandatory. The finish also prevents particle adherence, ensuring product purity throughout the process.Q: When should you choose a steel wire mesh with square holes for your production line?

A: Square-hole steel wire mesh is ideal when uniform particle size filtration is required. It is chosen for tasks where precise separation and consistent throughput are necessary, such as in tablet production, powder sieving, and liquid filtration.Q: Where is this steel wire mesh manufactured and exported from?

A: This mesh is manufactured, supplied, and exported across India by experienced companies specializing in pharma-industry solutions. With a strong network, we also serve international clients seeking quality-assured mesh for their pharmaceutical operations.Q: What is the process for surface treatment of the mesh?

A: The steel mesh undergoes a rigorous polishing process which removes impurities, improves corrosion resistance, and achieves a smooth, hygienic finish. This ensures compliance with pharma standards and facilitates easy maintenance.Q: How does using steel wire mesh benefit pharmaceutical manufacturers?

A: Steel wire mesh increases operational efficiency by ensuring reliable filtration and separation, reduces downtime due to its durability and easy-clean surface, and helps maintain stringent quality standards required for pharmaceutical production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh Category

Nylon Wire Mesh

Price 12 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Hole Shape : Other , Square

Mesh Type : Iron Wire Mesh

Color : White

Product Type : Wire Mesh

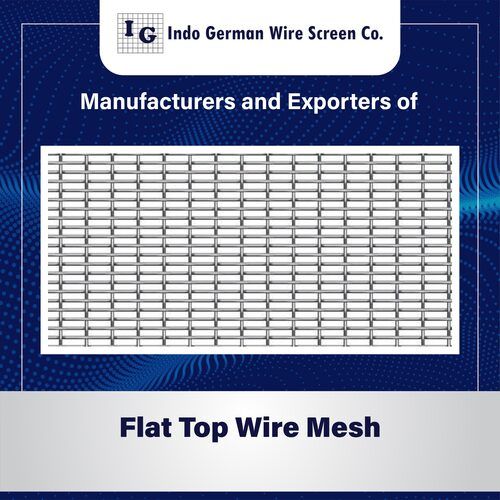

Flat Top Wire Mesh

Price 120 INR

Minimum Order Quantity : 10 Square Meters

Hole Shape : Other , Rectangular

Mesh Type : Steel Wire Mesh

Color : Sliver

Product Type : Wire Mesh

Plastic Mesh

Price 6.00 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Hole Shape : Other , Diamond

Mesh Type : Steel Wire Mesh

Color : Green

Product Type : Wire Mesh

PVC Welded Mesh

Price 120 INR / Square Meter

Minimum Order Quantity : 10 Square Meters

Hole Shape : Square Hole

Mesh Type : Steel Wire Mesh

Color : Green

Product Type : Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry