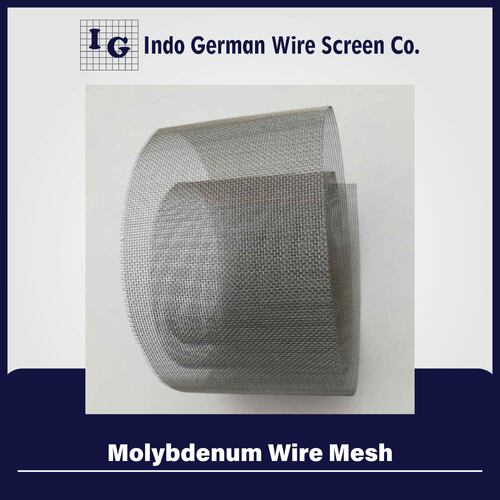

Molybdenum Wire Mesh

Price 50 INR/ Unit

Molybdenum Wire Mesh Specification

- Aperture

- 0.20 mm - 1 mm

- Surface Treatment

- Cleaned/Bright

- Hole Shape

- Square

- Wire Gauge

- 35-90 mesh (customizable)

- Length

- 10 m, 30 m (custom lengths available)

- Product Type

- Woven Wire Mesh

- Mesh Type

- Metal Mesh

- Mesh Style

- Plain Weave

- Material

- 99.95% pure Molybdenum

- Alloy

- Pure Molybdenum

- Application

- High-temperature furnace, filtration, aerospace, electronics

- Dimensions

- width 10 mm - 1000 mm, length as required

- Wire Diameter

- 0.03 mm - 0.2 mm

- Weight

- Varies with size and mesh count

- Color

- Silver Gray

- Tensile Strength

- 370 MPa (approximate)

- Edge Type

- Straight cut or rolled

- Melting Point

- 2623°C

- Chemical Resistance

- Excellent against acids and alkalis

- Standards

- GB/T 4182-2018, ASTM B386

- Operating Temperature

- Up to 1900°C in vacuum or non-oxidizing atmospheres

- Electrical Conductivity

- High

- Packing

- Packed in wooden cases, moisture-proof packaging

About Molybdenum Wire Mesh

We have become a major supplier of these products into an extensive range of markets and applications across India and the globe. Our clients select our range of products for their economical prices, dimensional preciseness, and high-durability.These high-quality products are manufactured at our premises using quality tested raw materials and components according to industry quality standards. Its use inSpecialized Industrial Applications likeElectric-Vacuum Industry,Oil and Gas Industry,Aerospace Industry ,Nuclear Power Industry,Chemical Material and Food Particle Filtration,Heating Elements in High-Temperature Furnaces etc.Superior High-Temperature Stability

With a melting point of 2623C and operational capability up to 1900C, our molybdenum wire mesh reliably maintains structural integrity in extreme heat. Its an ideal choice for environments such as high-temperature furnaces and advanced aerospace systems, offering exceptional durability and consistent performance.

Versatility in Application and Design

Available in wire gauges from 35 to 90 mesh, aperture sizes ranging from 0.20 mm to 1 mm, and various surface finishes, our mesh meets the requirements of filtration, electronic assemblies, and chemical processing. Custom lengths, widths (10 mm to 1000 mm), and edge types are also offered to support your specific projects.

FAQs of Molybdenum Wire Mesh:

Q: How is molybdenum wire mesh used in high-temperature applications?

A: Molybdenum wire mesh is commonly used in high-temperature environments, such as furnace linings, heating elements, and shielding in aerospace, due to its stability at up to 1900C in vacuum or non-oxidizing conditions.Q: What benefits does 99.95% pure molybdenum provide in wire mesh?

A: Utilizing 99.95% pure molybdenum ensures excellent chemical resistance against acids and alkalis, high tensile strength, and reliable electrical conductivity, making the mesh suitable for demanding applications and enhancing product longevity.Q: When should molybdenum wire mesh be selected over other metal meshes?

A: Select molybdenum wire mesh when you require superior performance in high-temperature or corrosive environments, especially where standard steels or other alloys may fail or degrade.Q: Where can this wire mesh be installed and utilized effectively?

A: This mesh is versatile and can be installed in vacuum furnaces, filtration units for aggressive chemicals, aerospace components, and sensitive electronic equipment, providing areliablesolution wherever heat resistance is critical.Q: What is the manufacturing process of the molybdenum wire mesh?

A: The mesh is manufactured from high-purity molybdenum wire, woven into the desired mesh count and pattern (such as plain weave), then treated for cleanliness and surface finish before being straight cut or rolled, and packed securely for delivery.Q: How does the meshs structure benefit advanced filtration or separation processes?

A: The uniform aperture sizes and high mechanical strength allow precise filtration, separation of fine particles, and protect sensitive components, making the mesh a vital component in both industrial and scientific filtration systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh By Material Category

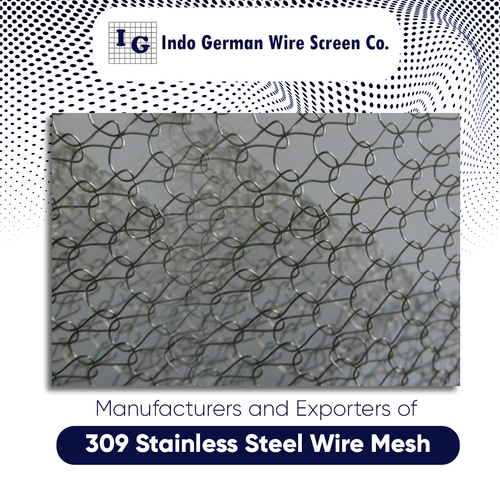

309 stainless steel wire mesh

Price 1000-100000.00 INR / Foot

Minimum Order Quantity : 50 Feet

Color : Silver

Application : Other, High temperature filtration, furnace screening, chemical processing, power plant, and metallurgy

Hole Shape : Square Hole

Material : Stainless Steel

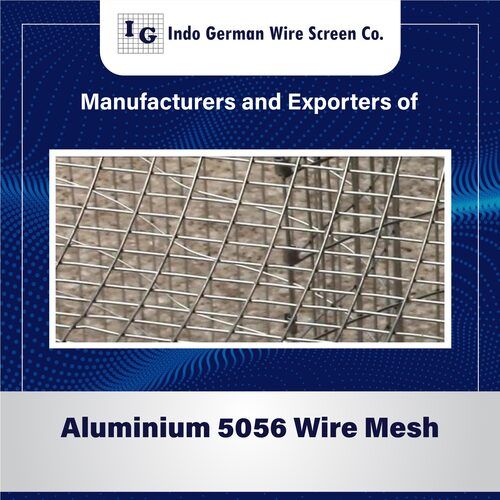

Aluminium 5056 Wire Mesh

Price 9 INR

Minimum Order Quantity : 10 Square Foots

Color : Sliver

Application : Other, Filtration, Sieving, Insect Screens, Industrial Separation, Construction

Hole Shape : Square Hole

Material : Steel

Inconel 600 Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver Grey

Application : Other, High temperature filtration, Chemical processing, Aerospace, Power generation

Hole Shape : Other , Square or Rectangular

Material : Other, Inconel 600

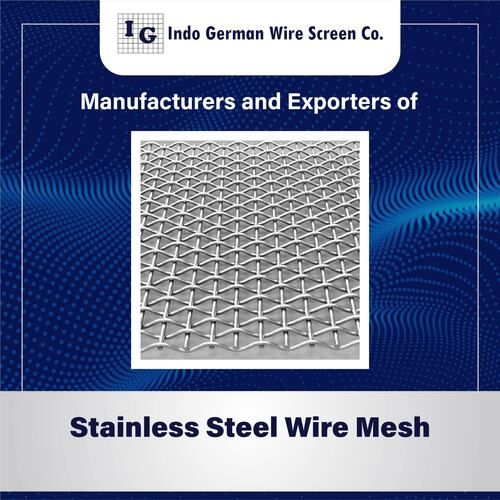

Stainless Steel Wire Mesh

Price 150 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Color : Silver

Application : Food Industry, Solar Industry

Hole Shape : Square Hole

Material : Stainless Steel

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry