Monel 400 Wire Mesh

Monel 400 Wire Mesh Specification

- Wire Gauge

- 10 to 25 SWG

- Hole Shape

- Square Hole

- Surface Treatment

- Annealed / Pickled

- Aperture

- 1 mm - 10 mm (Customizable)

- Length

- 30 m (Standard), Customization Available

- Product Type

- Wire Mesh

- Mesh Type

- Steel Wire Mesh

- Mesh Style

- Woven / Welded

- Material

- Steel

- Alloy

- Monel 400

- Application

- Filtration, Sieving, Chemical Industries, Marine Applications

- Dimensions

- Width: 1 m - 2 m (Standard)

- Wire Diameter

- 0.1 mm - 2 mm

- Weight

- Variable as per size and mesh

- Color

- Sliver

Monel 400 Wire Mesh Trade Information

- Minimum Order Quantity

- 10 Square Foots

- Supply Ability

- 10 Square Foots Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Carton box

- Main Domestic Market

- All India

About Monel 400 Wire Mesh

We are the leading name in the market to offer our renowned clients the best range of Monel 400 Wire Mesh that exhibits high strength and excellent rust resistance. Our offered wire mesh is commonly used in a wide range of applications including electrical and electronic components, heat exchangers and water heaters, processing equipment, the petroleum industry, marine fixtures, pumps and valves. Offered Monel 400 Wire Mesh is available in different variety of sizes and specifications. This product is appreciated for its excellent tensile strength, corrosion proof and fine finish.

Exceptional Corrosion Resistance

Monel 400 Wire Mesh is prized for its excellent corrosion resistance, notably in environments containing seawater and acids. This makes it particularly suitable for marine and chemical industry applications where lesser materials would degrade rapidly. Its corrosion-resistant properties ensure a long-lasting, reliable performance even in challenging conditions.

High Strength and Versatility

Constructed with a high tensile strength that varies by diameter, this wire mesh can withstand demanding mechanical loads. The mesh is available in customizable sizes and roll lengths, allowing for precise adaptation to specific project needs. Its robust mechanical properties and adaptability make it an optimal choice for filtration, sieving, and industrial separation processes.

Customization and Quality Assurance

Manufactured to ASTM B164/B906 standards, Monel 400 Wire Mesh can be tailored in terms of aperture size, wire diameter, roll length, and surface treatment. Offered in rolls or as per client request, every mesh is produced for high purity and density, with strict attention to quality and customer specifications from leading exporters, manufacturers, and suppliers in India.

FAQs of Monel 400 Wire Mesh:

Q: How is Monel 400 Wire Mesh used in industrial applications?

A: Monel 400 Wire Mesh is commonly utilized in filtration, sieving, and separation processes across chemical, marine, and industrial sectors due to its robust construction and excellent resistance to corrosive environments.Q: What is the customization process for Monel 400 Wire Mesh specifications?

A: Clients can specify desired aperture (110 mm), wire diameter (0.12 mm), roll length (15 m, 30 m, or custom), width (12 m), and surface treatment (annealed/pickled). Manufacturers ensure the mesh aligns with requested requirements while meeting ASTM B164/B906 standards.Q: When should Monel 400 Wire Mesh be chosen over other materials?

A: It is best selected for applications demanding high corrosion resistance to seawater and acids, elevated thermal performance (up to 600C), and strong mechanical integritysuch as in chemical plants, marine construction, and filtration tasks.Q: Where are these wire meshes typically installed?

A: Monel 400 Wire Mesh is widely used in filtration systems, marine vessels and offshore structures, chemical processing plants, and any environment where exposure to corrosive agents is likely.Q: What benefits does the smooth, bright finish provide?

A: The premium finish minimizes surface irregularities, reduces the risk of contaminant adhesion, and offers enhanced cleanability, making it suitable for high-standard industrial environments.Q: How does Monel 400 Wire Mesh ensure longevity under severe conditions?

A: The unique nickel-copper alloy composition offers high purity and density, conferring robust mechanical strength and remarkable corrosion resistance, which together extend the service life even under harsh operational circumstances.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh By Material Category

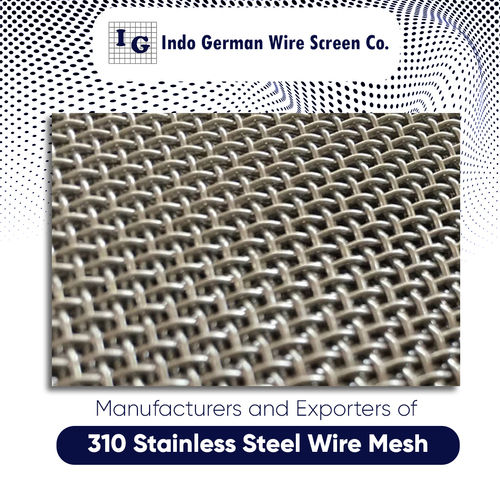

310 Stainless Steel Wire Mesh

Price Range 150.00 - 750.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Product Type : Wire Mesh

Color : Sliver

Mesh Type : Steel Wire Mesh

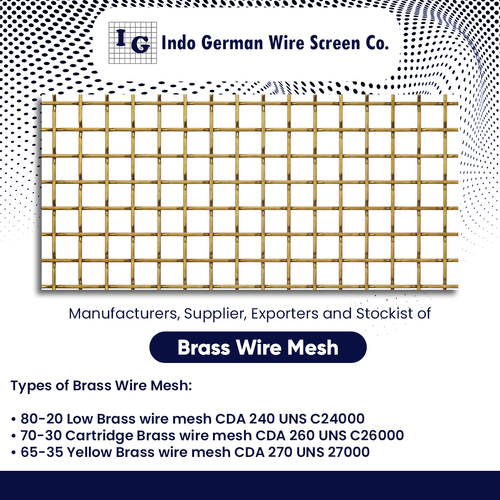

Brass Wire Mesh

Price Range 75.00 - 150.00 INR

Minimum Order Quantity : 10 Square Foots

Product Type : Wire Mesh

Color : Golden

Mesh Type : Iron Wire Mesh

Copper Knitted Wire Mesh

Price 580 INR

Minimum Order Quantity : 10 Kilograms

Product Type : Wire Mesh

Color : Golden

Mesh Type : Steel Wire Mesh

Wire Mesh in SS/MS/Spring Steel/Brass

Price Range 25.00 - 250.00 INR

Minimum Order Quantity : 100 Square Foots

Product Type : Wire Mesh

Color : Sliver

Mesh Type : Steel Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry