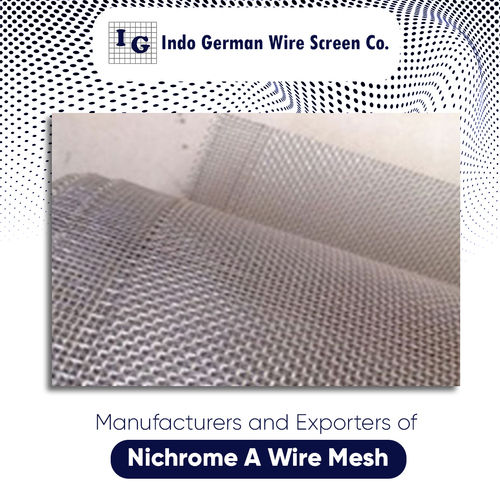

Nichrome Wire Mesh

Nichrome Wire Mesh Specification

- Length

- Available up to 30 meters

- Wire Gauge

- 14 to 28 SWG

- Aperture

- 2 mm to 25 mm

- Hole Shape

- Square Hole

- Surface Treatment

- Bright Annealed

- Product Type

- Wire Mesh

- Mesh Type

- Steel Wire Mesh

- Mesh Style

- Woven

- Material

- Steel

- Alloy

- Nichrome (Nickel-Chromium)

- Application

- Filtration, Heating Elements, Laboratory, Construction

- Dimensions

- Custom sizes available

- Wire Diameter

- 0.25 mm to 2 mm

- Weight

- Varies as per size and gauge

- Color

- Sliver

Nichrome Wire Mesh Trade Information

- Minimum Order Quantity

- 10 Square Foots

- Supply Ability

- 10 Square Foots Per Day

- Delivery Time

- 1 Days

- Packaging Details

- Carton box

- Main Domestic Market

- All India

About Nichrome Wire Mesh

Special Features :

- This nickel based wire mesh is reckoned for its stable thermal properties and good mechanical attributes.

- Oxidation proof and high temperature protected

- Useful for aerospace designing, medical instruments production and desalination process

- Can resist shock, deformation proof

Specifications of Nichrome A wire mesh

- Material: Cr20Ni80, Cr15Ni60 and Cr20Ni35.

- Weaving type: plain weave and twill weave.

- Wire diameter: 0.0014" - 0.063".

- Mesh size: 4 mesh - 325 mesh.

- Width: 0.1m - 1.5m.

Superior Performance at High Temperatures

Engineered for environments requiring temperature resistance of up to 1200C, Nichrome Wire Mesh endures challenging conditions without compromising structural integrity. Its ability to withstand extreme heat, coupled with notable corrosion resistance, makes it indispensable in applications such as industrial ovens, heaters, and scientific research laboratories, where reliability is paramount.

Flexible Customization for Diverse Applications

This mesh is manufactured in a variety of sizes, gauging from 14 to 28 SWG, with opening sizes from 2 mm to 25 mm and wire diameters between 0.25 mm and 2 mm. Whether you require square holes, various mesh styles, or precise lengths up to 30 meters, customization ensures suitability for filtration, heating elements, and construction frameworks. Supplied as rolls or cut pieces, it adapts to both bulk and specialized orders.

FAQs of Nichrome Wire Mesh:

Q: How is Nichrome Wire Mesh typically used in industrial and laboratory settings?

A: Nichrome Wire Mesh is primarily utilized for its high heat and corrosion resistance, making it ideal for filtration, heating elements, construction reinforcements, and laboratory experiments. Its durability ensures it performs reliably in both industrial processes and scientific research.Q: What are the benefits of choosing Nichrome Wire Mesh for high-temperature applications?

A: The wire mesh is specifically designed to withstand temperatures up to 1200C, ensuring longevity and consistent performance in extreme heat conditions. Its excellent corrosion resistance also offers added durability, reducing maintenance and replacement frequency.Q: Where can I request custom sizes or specifications for Nichrome Wire Mesh?

A: Custom sizes, thicknesses, and opening dimensions can be requested directly from the exporter, manufacturer, supplier, or trader in India. You can tailor the mesh to fit your specific application needs, whether for industrial, commercial, or research use.Q: When should I select plain versus twill weave for my application?

A: A plain weave is generally chosen for applications requiring stable, fine filtration or uniform mesh structure, while a twill weave provides enhanced strength and flexibility, making it suitable for heavier filtration and structural applications.Q: What is the manufacturing process for Nichrome Wire Mesh?

A: Nichrome wire is drawn to the desired gauge, woven into mesh using plain or twill patterns, and then bright annealed to increase resilience and longevity. The mesh can be produced with either plain or selvaged edges, and cut to size or supplied in rolls.Q: How do I benefit from the bright annealed surface treatment?

A: Bright annealing enhances the meshs oxidation resistance and mechanical strength, resulting in a smoother surface and ensuring the material maintains its properties over extended use, especially in harsh environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh By Material Category

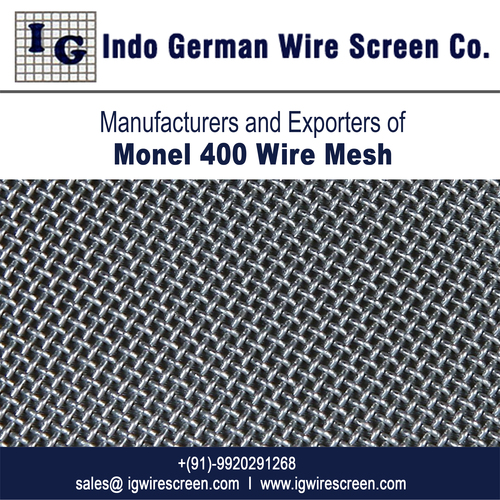

Monel 400 Wire Mesh

Price Range 500.00 - 2000.00 INR

Minimum Order Quantity : 10 Square Foots

Surface Treatment : Other, Annealed / Pickled

Product Type : Wire Mesh

Color : Sliver

Stainless Steel 309 Wire Mesh

Price Range 220.00 - 750.00 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Surface Treatment : Mill Finish

Product Type : Wire Mesh

Color : Sliver

Hastelloy C22 Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Other, Bright, Pickled, Annealed

Product Type : Wire Mesh

Color : Metallic (SilverGrey)

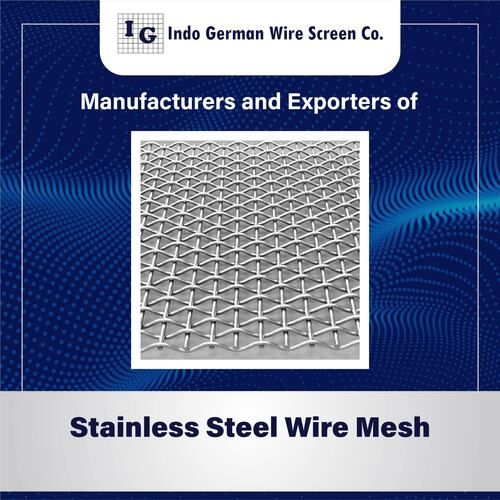

Stainless Steel Wire Mesh

Price 150 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Surface Treatment : Coated

Product Type : Wire Mesh

Color : Silver

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry