Monel Perforated Sheets

Price 50 INR/ Unit

MOQ : 1 Unit

Monel Perforated Sheets Specification

- Temper

- Soft, Hard, Half Hard

- Process

- Punching / Perforation

- Standard

- ASTM B127 / ASTM B366

- Surface Treatment

- Polished, Annealed

- Shape

- Rectangular, Square

- Material

- Monel 400, Monel K500

- Type

- Perforated Sheet

- Technique

- Cold rolled / Hot rolled

- Thickness

- 0.5 mm to 20 mm

- Application

- Chemical processing, Marine engineering, Oil and gas industries, Heat exchangers, Food processing

- Feature

- Corrosion resistant, High strength, Excellent weldability

About Monel Perforated Sheets

Monel 400is a combination of Nickel and Copper making it one of the most multipurpose and widely used nickel alloys. Monel comprises more than 60% andis a versatile alloy, as a copper-nickel alloy exhibits high strength and excellent corrosion resistance in a wide range of media, including sea water and in acidic and alkaline environments.Perforated Sheetsare thin sheets which are stamped, fabricated, or punched to create a pattern of holes, slots, and various aesthetic shapes to have uniform perforations throughout the entire surface. Depending on applications and requirements, patterns of perforated sheets can be round-staggered, round-straight, slotted holes. Although the process of perforating improves the exterior of metals, it has other useful special uses like protection and noise suppression.Theperforated sunshades and claddingsprovide privacy for the building residents without any obstruction of view while controlling interior climate, thus reducing the load of air conditioning and saving energy to a large extent.Perforated Sheets, fencesand banisters keep enclosed machines and other properties secure from damage and the safety of people.

Indo German Wire Screen Co.has in-house fabrication capabilities to provide custom perforated hole patterns for unique or specialty applications, if required.

Superior Corrosion Resistance

Monel perforated sheets offer outstanding resistance against corrosive environments, particularly in chemical processing, marine engineering, and oil and gas applications. The high nickel content and robust alloy composition preserve sheet integrity even under exposure to acids, seawater, and harsh chemicals, ensuring long service life.

Versatile Hole Patterns & Customization

With available hole patterns including round, square, and slotted, and open area percentages from 20% to 60%, these sheets can be tailored for optimal airflow, filtration, or mechanical requirements. Standard sizes are 1000 mm x 2000 mm, but custom dimensions and edge finishes are offered to precisely match your application needs.

FAQs of Monel Perforated Sheets:

Q: How are Monel perforated sheets manufactured?

A: Monel perforated sheets are produced by cold or hot rolling Monel alloys, followed by precision punching or perforation techniques to create round, square, or slotted patterns. The sheets can then undergo surface treatments such as polishing or annealing for enhanced appearance and material properties.Q: What benefits do Monel perforated sheets provide in industrial applications?

A: These sheets are highly valued for their corrosion resistance, high strength, and excellent weldability. Their durability in harsh environments makes them ideal for chemical processing, marine engineering, oil and gas, heat exchangers, and food processing industries.Q: When should I select a particular hole pattern or open area percentage for my application?

A: Choice of hole pattern and open area percentage relies on your specific usage: round holes are preferred for general filtration; square holes for strength; and slotted for directional flow control. Open area percentage affects airflow, filtration, and weight20% to 60% can be selected based on desired performance and mechanical requirements.Q: Where can Monel perforated sheets be used most effectively?

A: Monel perforated sheets are ideally suited for environments that require exceptional corrosion resistance, such as marine settings, chemical processing plants, oil and gas facilities, heat exchangers, and hygienic food processing operations.Q: What is the standard packaging for Monel perforated sheets?

A: Sheets are securely packaged on wooden pallets using standard export packaging practices. This ensures protection during transit and ease of handling upon arrival at your facility.Q: How does the edge finish and surface treatment affect the product?

A: Smooth and mill edges contribute to safer handling and improved appearance, while surface treatments like polishing and annealing enhance corrosion resistance, durability, and overall sheet aesthetics.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Monel Perforated Sheets Category

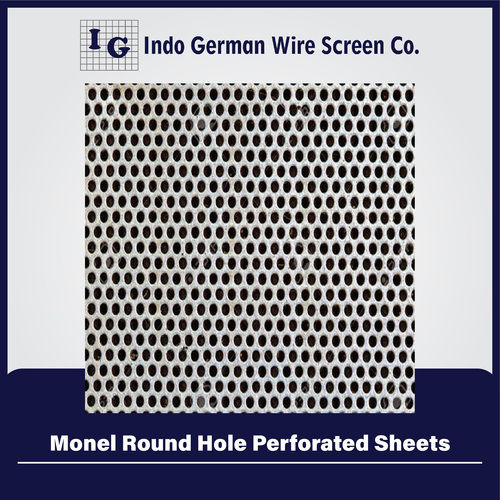

Monel Round Hole Perforated Sheets

Thickness : 0.5 mm to 5 mm

Temper : Hard, Soft, Half Hard

Type : Round Hole Perforated Sheet

Feature : Corrosion Resistant, High Strength, Durable

Material : Other , Monel (NickelCopper Alloy)

Application : Chemical Processing Equipment, Marine Engineering, Oil & Gas Industry, Power Generation, Heat Exchangers

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry