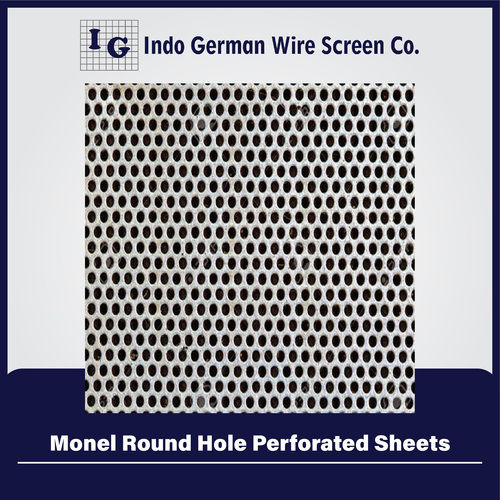

Monel Round Hole Perforated Sheets

Monel Round Hole Perforated Sheets Specification

- Standard

- ASTM B127, ASTM B165

- Surface Treatment

- Polished

- Temper

- Hard, Soft, Half Hard

- Process

- Punching / Perforating

- Shape

- Rectangular, Sheet

- Material

- Monel (Nickel-Copper Alloy)

- Type

- Round Hole Perforated Sheet

- Technique

- Perforated

- Thickness

- 0.5 mm to 5 mm

- Application

- Chemical Processing Equipment, Marine Engineering, Oil & Gas Industry, Power Generation, Heat Exchangers

- Feature

- Corrosion Resistant, High Strength, Durable

About Monel Round Hole Perforated Sheets

Monel Round Hole Perforated Sheets contain round hole patterns that can be staggered or straight lines. Staggered patterns put the holes out of alignment, while a straight line has holes arranged parallel and perpendicular to each other. There are three options for end margins, which include finished, unfinished, and blank. These high-quality products are manufactured at our premises using quality tested raw materials and components according to industry quality standards. we are the professional people delivering high-quality and superior-performance products that have been appreciated by all of our previous customers.Precision Perforation for Industrial Applications

Our Monel Round Hole Perforated Sheets are crafted using advanced perforation techniques, ensuring uniformity in hole size and optimal open area. With customizable dimensions and high strength, these sheets are ideal for filtration, screening, and structural applications in challenging environments. Their superior corrosion resistance, inherent to the Monel alloy, supports dependable long-term performance.

Versatile Options and Quality Standards

Available in widths from 600 mm to 1500 mm and lengths up to 3000 mm, our sheets comply with ASTM B127 and B165 standards. You can choose from multiple edge finishes, thickness, temperament, and surface treatments. Each sheet can be supplied annealed or pickled and is securely packaged on wooden pallets or in bundles to ensure safe delivery.

FAQs of Monel Round Hole Perforated Sheets:

Q: How are Monel Round Hole Perforated Sheets manufactured?

A: These sheets are made by punching or perforating precise round holes into Monel nickel-copper alloy sheets using specialized machinery. This technique ensures accuracy in hole size and distribution, allowing for custom open area percentages and dimensions.Q: What applications are these perforated sheets most suitable for?

A: Monel perforated sheets are ideal for chemical processing, marine engineering, oil & gas, power generation, and heat exchangers. Their corrosion resistance and high strength make them the preferred choice in harsh or corrosive environments.Q: When should I opt for Monel over other materials?

A: Monel is chosen over other materials when the application requires exceptional resistance to corrosion, particularly in marine or chemical processing settings, combined with a need for structural durability and high temperature stability.Q: Where can these perforated sheets be installed?

A: They are installed in equipment, frameworks, and enclosures within industrial plants, marine vessels, offshore oil & gas platforms, and power plantsanywhere durable and corrosion-resistant filtration or structural sheets are necessary.Q: What is the benefit of various open area percentages in these sheets?

A: Different open area percentages (15% to 60%) allow for controlled air, liquid, or light passage. The required percentage depends on filtration, screening, or ventilation needs of the specific application.Q: How does the surface treatment enhance sheet performance?

A: Surface treatments like polishing, annealing, and pickling improve the sheets appearance, increase corrosion resistance, and remove impurities from the manufacturing process, resulting in a smoother, cleaner finish suitable for demanding environments.Q: What packaging options are available for delivery?

A: Sheets are shipped either on robust wooden pallets or bundled securely to protect against damage during transit, ensuring they arrive in pristine condition for immediate fabrication or installation.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Monel Perforated Sheets Category

Monel Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : Corrosion resistant, High strength, Excellent weldability

Standard : ASTM B127 / ASTM B366

Material : Other , Monel 400, Monel K500

Thickness : 0.5 mm to 20 mm

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry