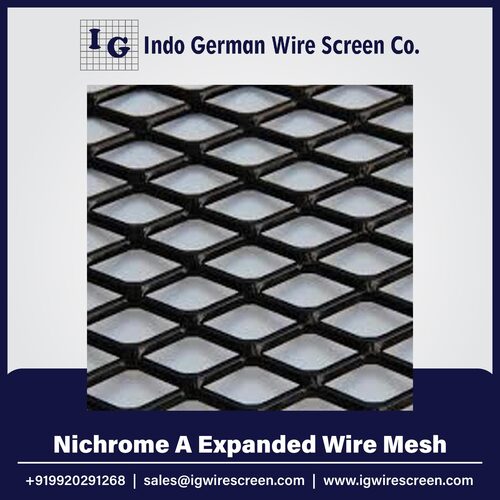

Nichrome A Expanded Wire Mesh

Price 50 INR/ Unit

Nichrome A Expanded Wire Mesh Specification

- Wire Gauge

- 24 SWG

- Length

- 1000 mm

- Aperture

- 5 mm

- Hole Shape

- Hexagonal

- Surface Treatment

- Uncoated

- Product Type

- Expanded Wire Mesh

- Mesh Type

- Open Mesh

- Mesh Style

- Expanded

- Material

- Nichrome A

- Alloy

- Nickel Chromium

- Application

- Heating Elements, Electric Furnaces, Toasters

- Dimensions

- 1000 mm x 300 mm

- Wire Diameter

- 0.56 mm

- Weight

- 0.85 kg (approx. per sheet)

- Color

- Silver

About Nichrome A Expanded Wire Mesh

Nichrome is an alloy of nickel and chrome according to different chemical compositions and can be divided into Cr20Ni80, Cr15Ni60 and Cr20Ni35. Nichrome is made of nichrome wire and has outstanding ductility, oxidation resistance, high tensile strength, sulphur resistance and other features. Expanded Metal Mesh is available in numerous shapes but the most common is the diamond shaped aperture fashioned by an expanding machine by using a pressured stretching and slitting process to convert solid metal sheets into expanded mesh. The mesh is slit or perforated from metal sheets and is stretched to form a joint-less single piece grill with no interwaves or joints. Since it is manufactured from one single sheet, it is ideal for model making and forming.

High Temperature Durability

This Nichrome A Expanded Wire Mesh is specifically designed for use in applications that demand resistance to extreme heat. With a maximum working temperature of 1100C, it reliably performs in electric furnaces and heating appliances, ensuring consistent operation under challenging thermal conditions.

Superior Corrosion Resistance

Constructed from high-grade Nickel Chromium alloy, the mesh exhibits strong resistance to oxidation and corrosion. This quality makes it ideal for long-term use in harsh industrial settings, contributing to lower maintenance and replacement costs over time.

Precision Manufacturing and Versatility

Each mesh sheet is crafted with a precise 5 mm hexagonal aperture and accurately measured dimensions, providing uniformity and optimal performance. Its open mesh style enhances airflow and heat distribution, making it suitable for various thermal and electrical applications, from heating elements to toasters.

FAQs of Nichrome A Expanded Wire Mesh:

Q: How is the Nichrome A Expanded Wire Mesh typically used in industry?

A: This mesh is primarily utilized in heating elements, electric furnaces, and toasters due to its ability to withstand high temperatures and deliver efficient electrical conductivity. Its expanded open mesh facilitates even heat distribution, making it highly effective in thermal applications.Q: What benefits does the Nichrome A Expanded Wire Mesh offer over other materials?

A: Compared to standard wire meshes, Nichrome A mesh provides superior heat resistance (up to 1100C) and enhanced corrosion protection. Its high electrical resistivity and longevity reduce the frequency of replacements, offering better value and efficiency in industrial settings.Q: When should I consider using expanded mesh design over woven mesh?

A: An expanded mesh design, like this product, should be selected when airflow, strength, and durability are crucial. The open hexagonal apertures allow ample heat and air passage, which is beneficial for applications needing rapid heat transfer or ventilation, unlike woven meshes that may restrict flow.Q: Where can Nichrome A Expanded Wire Mesh be installed?

A: This mesh is suitable for installation in various thermal and electrical devices, such as industrial heating elements, laboratory furnaces, and domestic toasters. Its robust design and corrosion-resistant alloy enable effective use in both industrial and domestic environments.Q: What is the manufacturing process of this expanded wire mesh?

A: The mesh is produced by slitting and stretching Nichrome A alloy sheets, forming uniform hexagonal apertures. This process maintains the materials strength while minimizing waste, resulting in a mesh that is both lightweight and structurally reliable.Q: How does the uncoated surface and straight cut edge contribute to product performance?

A: The uncoated silver surface ensures maximum heat and electrical conductivity, while the straight cut edge provides a clean finish for seamless integration into assemblies, especially critical for precise installations in heating and furnace applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Expanded Mesh Category

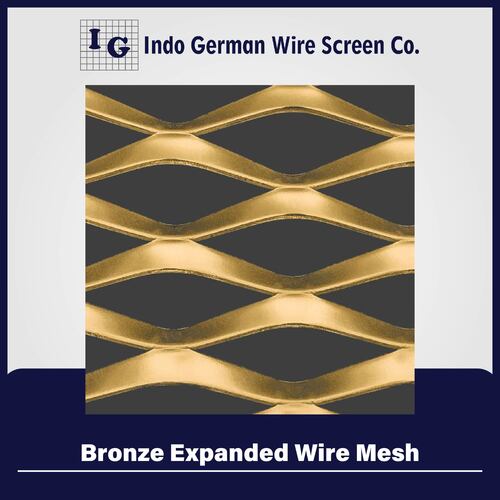

Bronze Expanded Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Bronze

Mesh Type : Other , Expanded

Mesh Style : Expanded Mesh

Product Type : Wire Mesh

Nickel Expanded Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Nickel

Mesh Type : Other , Heavy Duty

Mesh Style : Other , Expanded

Product Type : Other, Expanded Mesh

Stainless Steel Welded Expanded Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Mesh Type : Steel Wire Mesh

Mesh Style : Welded Mesh

Product Type : Wire Mesh

Stainless Steel Expanded Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Mesh Type : Steel Wire Mesh

Mesh Style : Rope Mesh

Product Type : Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry