Nichrome A Plain Weave Wire Mesh

Price 50 INR/ Unit

Nichrome A Plain Weave Wire Mesh Specification

- Length

- Standard rolls of 15 m / 30 m (can be customized)

- Aperture

- 0.15 mm to 2 mm

- Hole Shape

- Square

- Wire Gauge

- 40 SWG to 10 SWG

- Surface Treatment

- Coated

- Product Type

- Wire Mesh

- Mesh Type

- Woven Mesh

- Mesh Style

- Plain Mesh

- Material

- Nichrome

- Alloy

- Nickel-Chromium (Cr20Ni80/Nichrome A)

- Application

- Other

- Dimensions

- Custom sizes available (width up to 4 ft)

- Wire Diameter

- 0.12 mm to 3 mm

- Weight

- Depends on mesh configuration and size

- Color

- Gray

- Packing

- Rolls wrapped with moisture-proof paper or as per customer requirement

- Edge Type

- Plain, selvage available upon request

- Industry Usage

- Heating elements, thermocouple protection, chemical processing, laboratory filtration

- Tensile Strength

- High tensile strength suitable for industrial use

- Operating Temperature

- Up to 1200°C

- Standard ASTM

- A580/A580M-18

- Melting Point

- 1400°C (approx.)

- Corrosion Resistance

- Excellent resistance to oxidation and corrosion

- Mesh Count

- 10 to 200 mesh per inch

Nichrome A Plain Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Nichrome A Plain Weave Wire Mesh

We have become a major supplier of these products into an extensive range of markets and applications across India and the globe. Our clients select our range of products for their economical prices, dimensional preciseness, and high-durability.we are the professional people delivering high-quality and superior-performance products that have been appreciated by all of our previous customers.

Indo German Wire Screen Co. manufacturing and exporting high quality Nichrome A Plain Weave Wire Mesh worldwide.

Outstanding Durability in Extreme Environments

Manufactured with Nichrome A alloy, this plain weave wire mesh is engineered for resilience under harsh conditions. Its high melting point of approximately 1400C and top-tier resistance to corrosion and oxidation make it a reliable choice for prolonged use in high-temperature and chemically reactive environments. The robust weaving enables consistent performance and longevity across various industrial sectors.

Versatile Applications Across Industries

This wire mesh is designed for multifunctionality, serving vital roles in heating elements, thermocouple protection, chemical processing, and scientific laboratory filtration. The diverse range of mesh counts, wire gauges, apertures, and customizable dimensions ensure it can be adapted to specific processes. Its compliance with ASTM standards makes it an asset for critical and precise applications.

FAQs of Nichrome A Plain Weave Wire Mesh:

Q: How is Nichrome A Plain Weave Wire Mesh typically used in industrial settings?

A: Nichrome A Plain Weave Wire Mesh is widely used in heating elements, thermocouple protection tubes, chemical filtration, and laboratory filtration processes. Its excellent heat and corrosion resistance make it suitable for applications that require consistent performance in extreme conditions.Q: What benefits does Nichrome A mesh provide over other materials?

A: Compared to other materials, Nichrome A mesh offers exceptional high-temperature resilience (up to 1200C), superior tensile strength, and excellent resistance to oxidation and corrosion, ensuring durability and reliability in demanding environments.Q: Where can Nichrome A Plain Weave Wire Mesh be installed?

A: This mesh can be installed in various environments, including laboratories, industrial heaters, chemical processing plants, and any application areas needing robust filtration and thermal protection. Custom sizing allows seamless integration at different stages in manufacturing or research facilities.Q: What is the standard process for ordering customized mesh configurations?

A: You can request custom configurations by specifying mesh count, wire diameter, roll length, width, and edge type. Manufacturers accept orders as per ASTM A580/A580M-18 standards, providing packaging and dimensions tailored to individual project requirements.Q: When should you consider using selvage edges on the mesh?

A: Selvage edges are recommended when additional edge strength is needed to prevent fraying, especially in applications involving frequent handling or movement of the mesh. Selvage can be requested to enhance durability for specific industrial operations.Q: How does Nichrome A wire mesh benefit filtration and heating applications?

A: Its uniform plain weave and precise apertures ensure consistent filtration efficiency, while its high melting point and robust build make it ideal for reliable performance in heating and high-temperature processes.Q: What surface treatment options are available for Nichrome A wire mesh?

A: The mesh typically comes coated to enhance corrosion resistance. Additional treatments or coatings can be applied based on specific requirements, ensuring optimal longevity for various industrial uses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plain Weave Wire Mesh Category

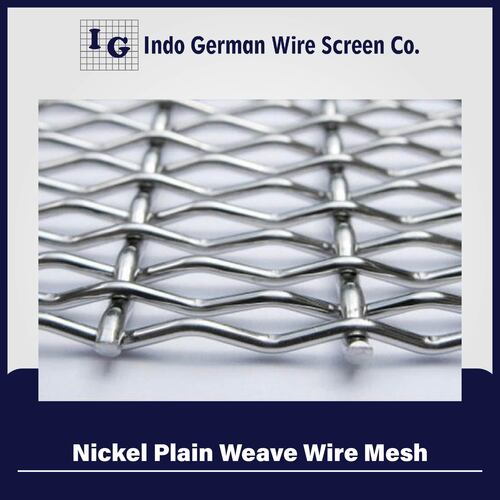

Nickel Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Coated

Product Type : Wire Mesh

Color : Gray

Mesh Style : Plain Mesh

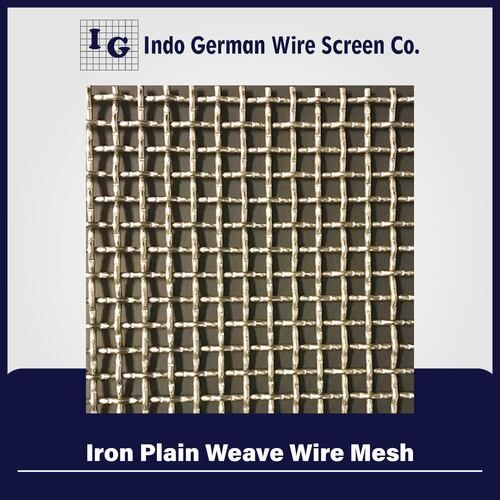

Iron Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Coated

Product Type : Wire Mesh

Color : Gray

Mesh Style : Plain Mesh

Inconel Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Other, Annealed / Bright

Product Type : Other, Plain Weave Wire Mesh

Color : Silver / Metallic Grey

Mesh Style : Other , Plain Weave

Bronze Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Coated

Product Type : Bronze Plain Weave Wire Mesh, Other

Color : Bronze

Mesh Style : Plain Weave, Other

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry