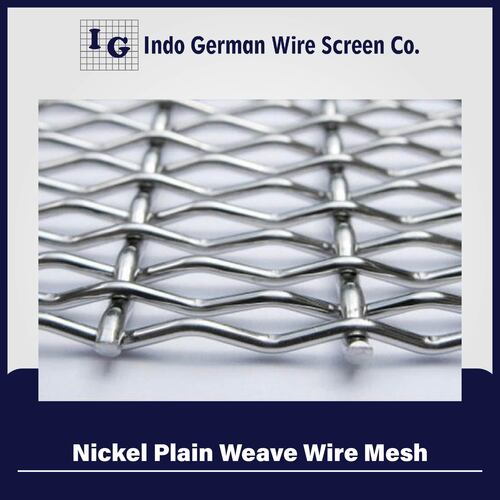

Nickel Plain Weave Wire Mesh

Price 50 INR/ Unit

Nickel Plain Weave Wire Mesh Specification

- Surface Treatment

- Coated

- Length

- Custom as per requirement, typically 30 meters per roll

- Aperture

- Standard, varies with mesh count (e.g. 0.053 mm - 2 mm)

- Hole Shape

- Square

- Wire Gauge

- Customizable, commonly ranges from 10 to 80 SWG

- Product Type

- Wire Mesh

- Mesh Type

- Plain Weave

- Mesh Style

- Plain Mesh

- Material

- Other

- Alloy

- Nickel 200 / Nickel 201

- Application

- Other

- Dimensions

- Custom sizes available, up to 1.22 m width

- Wire Diameter

- 0.03 mm to 2 mm (as per specification)

- Weight

- Varies depending on wire diameter and mesh size

- Color

- Gray

- Temperature Resistance

- Up to 1100C (2012F)

- Weave Type

- Plain Weave

- Roll Width

- Standard up to 1 meter

- Corrosion Resistance

- Excellent in alkaline media and neutral-salt environments

- Usage

- Chemical filtration, battery electrodes, aerospace, laboratory, electrolysis and gas diffusion

- Mesh Count

- Up to 400 mesh/inch

- Purity

- 99.6% Nickel content

- Standard Packing

- Rolled with moisture-proof paper or as required

Nickel Plain Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Nickel Plain Weave Wire Mesh

Exceptional Durability and Purity

Manufactured from Nickel 200 or Nickel 201 alloys with a minimum nickel content of 99.6%, this wire mesh provides excellent resistance to corrosion and high temperatures, ensuring longevity even in harsh chemical and industrial settings. The customizable mesh size and wire gauge allow for precise adaptation to various process needs.

Versatile Applications Across Industries

Due to its robust temperature and corrosion resistance, Nickel Plain Weave Wire Mesh is widely used in chemical filtration, batteries, aeronautics, laboratories, gas diffusion, and electrolysis. Its tailored specifications make it suitable for industries requiring high-purity, reliable, and long-lasting filtration or conductive materials.

FAQs of Nickel Plain Weave Wire Mesh:

Q: How is Nickel Plain Weave Wire Mesh typically used in industrial applications?

A: Nickel Plain Weave Wire Mesh serves key roles in chemical filtration, battery electrodes, aerospace components, laboratory filtration, gas diffusion, and electrolysis due to its stability, purity, and resistance to corrosive environments.Q: What benefits does high nickel purity provide for the meshs performance?

A: A nickel content of 99.6% enhances the meshs corrosion resistance, thermal stability, and chemical compatibility, making it ideal for use in alkaline media and high-temperature processes where material purity is crucial.Q: When should I consider choosing this mesh for my application?

A: Select this mesh when you require exceptional durability in corrosive or high-temperature environments, such as in chemical processing, research laboratories, battery manufacturing, or aerospace engineering.Q: Where is the Nickel Plain Weave Wire Mesh manufactured and supplied from?

A: This mesh is exported, manufactured, and supplied from India, serving clients globally in various industrial sectors, with quality standards suitable for international use.Q: What is the typical process for customizing mesh dimensions or specifications?

A: Custom sizes, wire gauges, and mesh counts can be specified during ordering. The mesh is produced according to client requirements regarding roll width (up to 1.22 meters), length (commonly 30 meters per roll), aperture size, and wire diameter.Q: How is the mesh packaged and shipped to ensure product integrity?

A: Standard packaging involves rolling the mesh in moisture-proof paper, with the option for alternative packaging as per request, ensuring the products integrity during transit and storage.Q: What are the advantages of the plain weave style in this mesh?

A: Plain weave offers a balance of mechanical strength and precise aperture control, facilitating reliable filtration and structural support while being easy to fabricate and customize for diverse applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plain Weave Wire Mesh Category

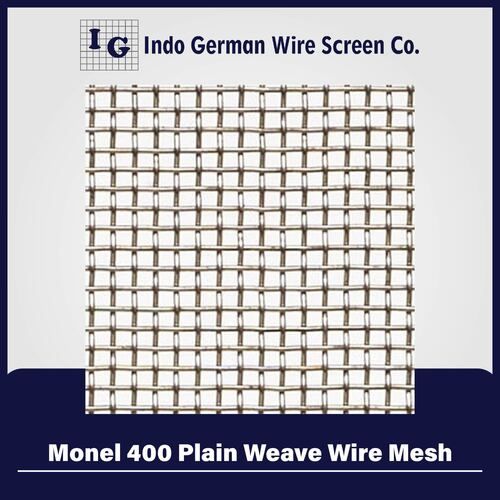

Monel 400 Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other, Industrial Screening Filtration Separation

Color : Metallic

Material : Other, Monel Alloy

Mesh Style : Plain Weave, Other

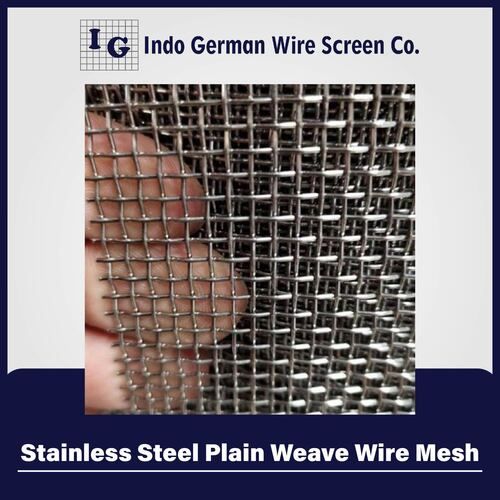

Stainless Steel Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other

Color : Gray

Material : Stainless Steel

Mesh Style : Plain Mesh

Hastelloy Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other, Filtration, Oil & Gas, Chemical Processing, Petrochemicals, Aerospace, Marine, Environmental, Food Processing

Color : Metallic Silver

Material : Other, Hastelloy (mainly C276, C22, C2000, B2 grades)

Mesh Style : Other , Plain Weave

Inconel Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other, Hightemperature filtration, Chemical processing, Aerospace, Heat Treatment

Color : Silver / Metallic Grey

Material : Other, Inconel (NickelChromium Alloy)

Mesh Style : Other , Plain Weave

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry