Tungsten Rectangular Wire Mesh

Price 50 INR/ Unit

Tungsten Rectangular Wire Mesh Specification

- Surface Treatment

- Coated

- Product Type

- Wire Mesh

- Mesh Type

- Tungsten Wire Mesh

- Material

- Tungsten

- Application

- Other

- Color

- Silver

Tungsten Rectangular Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Tungsten Rectangular Wire Mesh

Tungsten is an extremely hard metallic element that has an extremely high melting point and is corrosion resistant in many harsh environments. Tungsten is resistant to oxidation attack and corrosion in acidic and alkaline media and is used in elevated temperature filtration applications. Tungsten offers excellent high temperature mechanical characteristics and the smallest coefficient of thermal expansion among all metals. Tungsten is woven by tungsten wire, the surface can be block oxide, chemically cleaned, electrolytic polished, etc.Tungsten Rectangular Wire cloth plain weaveis the most frequently used weave in which each warp wire crosses interchangeably above and below each weft wire. Warp wires and weft wires usually have the same diameter.We offer an exclusive range ofTungsten Rectangular Wire Meshat unmatched quality and market leading prices.

Exceptional Material Properties

Manufactured from premium-grade tungsten, this rectangular wire mesh exhibits excellent strength, durability, and resistance to extreme conditions. Its coated, silver finish not only enhances its corrosion resistance but also contributes to a prolonged service life. These features make it suitable for both aggressive chemical settings and high-temperature operations.

Customized Solutions for Industry

With flexible mesh types and tailored surface coatings, manufacturers and suppliers in India offer bespoke solutions to meet specific client requirements. Whether the use is for filtration, separation, or electromagnetic shielding, the mesh can be precisely produced based on desired specifications, ensuring optimal performance for every application.

FAQs of Tungsten Rectangular Wire Mesh:

Q: How is Tungsten Rectangular Wire Mesh manufactured?

A: Tungsten Rectangular Wire Mesh is produced by weaving or welding high-purity tungsten wires into a rectangular pattern. After fabrication, the mesh undergoes a specialized silver coating process, ensuring added durability, corrosion resistance, and consistent performance across industrial applications.Q: What are the main uses of Tungsten Rectangular Wire Mesh?

A: This wire mesh is commonly used for filtration, sieving, chemical processing, and electromagnetic shielding due to its high strength and thermal resistance. Its robust nature also makes it suitable for applications in electronics, aerospace, and laboratory equipment.Q: Where can I source Tungsten Rectangular Wire Mesh in India?

A: Leading manufacturers, exporters, suppliers, and traders based in India offer Tungsten Rectangular Wire Mesh. They typically provide a range of mesh types, custom sizes, and surface treatments to suit diverse industry needs, both domestically and for export.Q: When should I choose tungsten wire mesh over other materials?

A: Tungsten wire mesh is ideal for environments requiring exceptional heat resistance, minimal corrosion, and superior mechanical strength. If your application involves high temperatures, aggressive chemicals, or needs fine electrical conductivity, choosing tungsten offers distinct advantages.Q: What benefits does the coated surface provide?

A: The coated surface enhances the meshs corrosion resistance and extends its lifespan, especially in challenging environments. This makes it suitable for use in processes that involve exposure to harsh chemicals, intense heat, or corrosive atmospheres.Q: How is the mesh used in industrial processes?

A: Industries utilize tungsten rectangular wire mesh for tasks like filtering particulate matter, reinforcing structures, and shielding sensitive equipment from electromagnetic interference. Its customizable mesh size allows it to be tailored for precise filtration or screening applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rectangular Wire Mesh Category

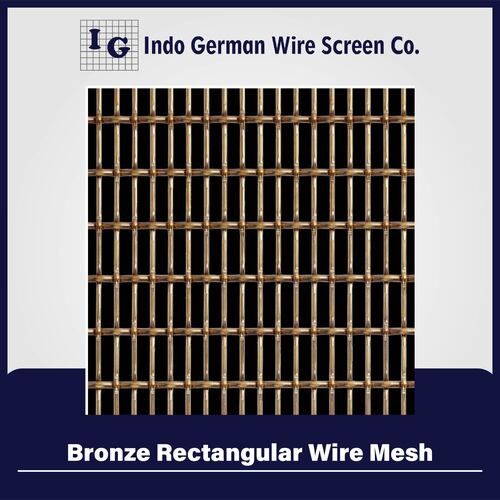

Bronze Rectangular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Other, Polished, Uncoated

Color : Bronze

Material : Other, Phosphor Bronze / Bronze Alloy

Mesh Type : Other , Rectangular Mesh

Stainless Steel Rectangular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Coated

Color : Silver

Material : Stainless Steel

Mesh Type : Steel Wire Mesh

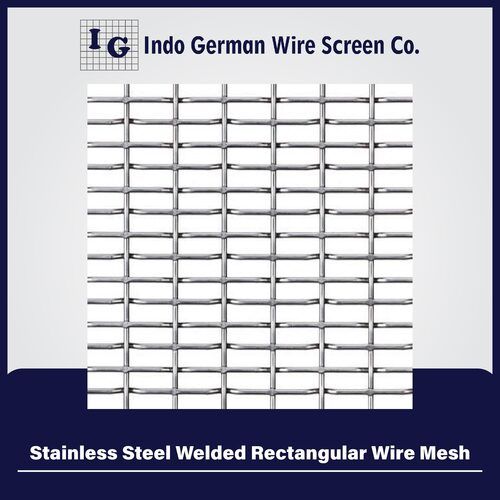

Stainless Steel Welded Rectangular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Coated

Color : Silver

Material : Stainless Steel

Mesh Type : Steel Wire Mesh

Copper Rectangular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Coated

Color : Copper

Material : Copper

Mesh Type : Copper Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry