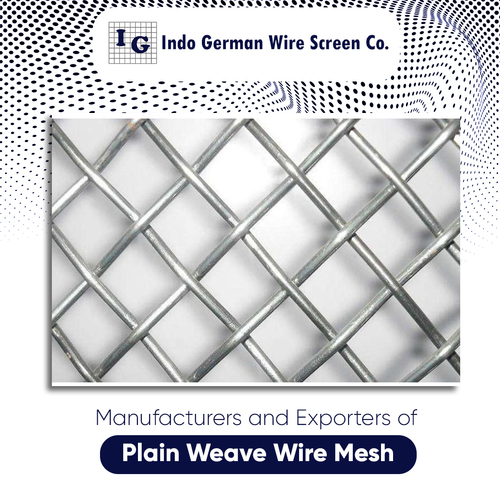

Plain Weave Wire Mesh

Plain Weave Wire Mesh Specification

- Surface Treatment

- Polished

- Product Type

- Wire Mesh

- Mesh Type

- Steel Wire Mesh

- Mesh Style

- Weave Wire Mesh

- Material

- Steel

- Color

- Silver

Plain Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 10 Square Foots

- Supply Ability

- 10 Square Foots Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Carton Box

- Main Domestic Market

- All India

About Plain Weave Wire Mesh

We are the leading names engaged provide our prestigious clients an optimum grade Plain Weave Wire Mesh is the most commonly used weave. Each weft wire passes alternately over and under each warp wire and vice versa. Our offered wire mesh is known for its features like square weaves, straight through square holes, thin and flexible, separation and classification of solid particles and very high flow rates. This wire mesh is available with apertures from 10.7mm (2 mesh) to 0.05mm (325 mesh). Offered Plain Weave Wire Mesh is obtainable in different sizes as per the varied demands of our valuable customers.

Product details

|

Material |

SS304 |

|

Brand |

Indo German |

|

Color |

Silver |

|

Material Grade |

304,316 and others |

|

Type |

Plain Weave Wire Mesh |

|

Usage/Application |

Industrial |

Premium Quality Steel Mesh

Precision-manufactured from robust steel, our plain weave wire mesh boasts a polished silver finish for enhanced corrosion resistance and mechanical strength. Engineered for both durability and visual appeal, this mesh is ideal for diverse industries requiring practical and aesthetic solutions.

Versatile Industrial Applications

Our steel wire mesh excels in filtration, screening, and fencing applications. Its consistent weave pattern delivers reliable particle separation and protection, making it a trusted choice for construction, mining, agriculture, and process industries across India.

FAQs of Plain Weave Wire Mesh:

Q: How is plain weave wire mesh produced?

A: Plain weave wire mesh is created by interlacing steel wires in a straightforward over-under pattern. This method ensures uniform openings throughout the mesh, enhancing strength and reliability for various industrial purposes.Q: What are the common uses of steel plain weave wire mesh?

A: Steel plain weave wire mesh is widely used for filtration, screening, fencing, and reinforcement. Its suitable for industrial processing, construction projects, equipment guarding, and agricultural applications due to its robust design and consistent mesh openings.Q: When should I choose polished steel wire mesh over other finishes?

A: Polished steel wire mesh is preferable when corrosion resistance and a refined, clean appearance are important. The polished finish makes it ideal for environments where hygiene and aesthetics are critical, as well as in settings exposed to moisture or chemicals.Q: Where can plain weave steel wire mesh be supplied from in India?

A: We supply plain weave steel wire mesh across India, serving diverse industries as exporters, manufacturers, suppliers, and traders. Our distribution network ensures timely delivery to major cities and industrial hubs nationwide.Q: What is the process for customizing plain weave wire mesh?

A: Customization begins with selecting appropriate wire gauge, mesh size, and dimensions. We then manufacture the mesh using precision weaving machinery, followed by surface polishing to achieve a silver finish as per client specifications.Q: How does the weave style benefit industrial applications?

A: The plain weave style provides uniform mesh openings, contributing to effective filtration and structural integrity. This ensures dependable performance in applications where particle separation or safeguarding machinery is essential.Q: What advantages does steel plain weave mesh offer over other materials?

A: Steel offers superior strength, longevity, and corrosion resistance compared to other materials. The polished surface adds to its durability, making it a cost-effective, low-maintenance choice for demanding environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh Category

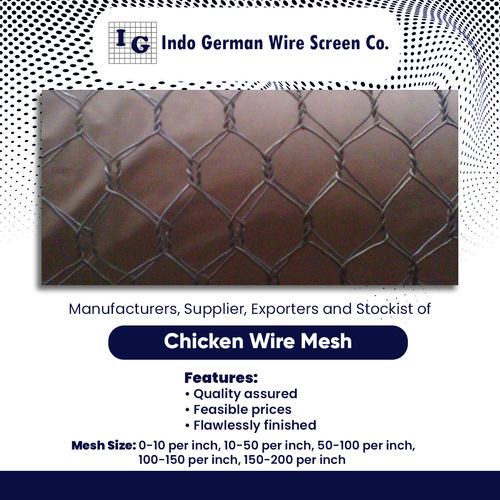

Chicken Wire Mesh

Price Range 350.00 - 2500.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Stainless Steel

Mesh Type : Steel Wire Mesh

Color : Silver

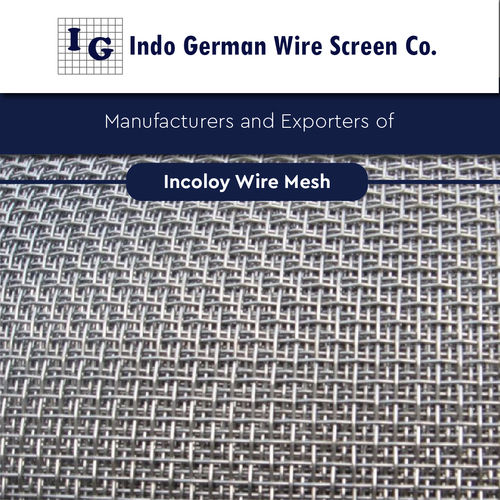

Incoloy Wire Mesh

Price 120 INR

Minimum Order Quantity : 10 Square Meters

Material : Other, Incoloy Alloy

Mesh Type : Other

Color : Silver

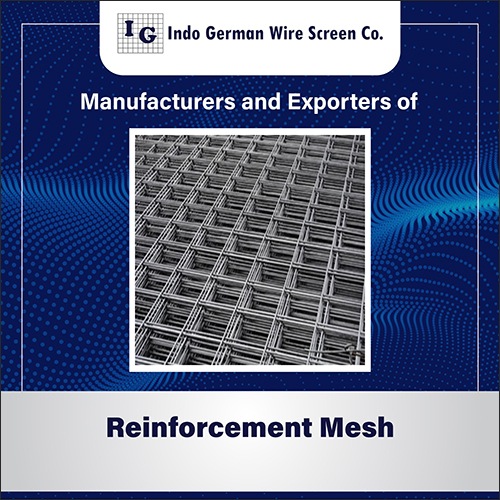

Reinforcement Mesh

Price Range 10.00 - 50.00 INR / Square Foot

Minimum Order Quantity : 400 Square Foots

Material : Iron

Mesh Type : Iron Wire Mesh

Color : Black

Wire Cloth

Price Range 40.00 - 400.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Material : Steel

Mesh Type : Steel Wire Mesh

Color : Silver

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry