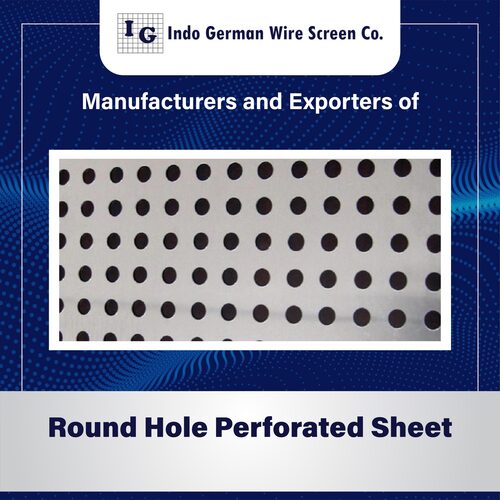

Round Hole Perforated Sheets

Price 50 INR/ Unit

Round Hole Perforated Sheets Specification

- Surface Treatment

- Polishing

- Usage

- Industrial

- Material

- Metal

- Type

- Perforated Sheets

- Size

- Standard

- Product Type

- Round Hole Perforated Sheets

- Color

- Silver

Round Hole Perforated Sheets Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Round Hole Perforated Sheets

We manufacture specialized products likeWire Mesh / Wire Netting, Perforated Sheets, Vibrating Screens, Conveyor Belts, Demister Pads, Super Wide Wire Mesh, Sifter Sieves, Filter Accessories, and Expanded Metal.We have become a major supplier of these products into an extensive range of markets and applications across the globe. Our clients select our range of products for their economical prices, dimensional preciseness, and high-durability.

Precision-Engineered Perforation

Our perforated sheets feature uniform round holes, meticulously crafted for industrial performance. This precision enables efficient air and light passage, making them ideal for filtration, screening, and architectural applications. The polished silver finish not only enhances visual appeal but also contributes to corrosion resistance, ensuring longevity and consistent performance in rigorous conditions.

Robust Metal Construction

Engineered from top-grade metal, these sheets deliver exceptional strength and stability. The comprehensive polishing process results in a smooth, reflective surface that resists tarnishing and ensures easy maintenance. Designed to meet standard sizing requirements, they integrate seamlessly into various industrial systems, supporting diverse operational needs.

FAQs of Round Hole Perforated Sheets:

Q: How are round hole perforated sheets manufactured?

A: Our round hole perforated sheets are produced using advanced machinery that punches precise, evenly spaced round holes into premium metal sheets. After perforation, each sheet undergoes thorough polishing to achieve a smooth and reflective silver finish, enhancing both appearance and resistance to corrosion.Q: What industries commonly use these perforated sheets?

A: These perforated sheets are primarily used in industrial settings, including factories, plants, and construction sites. They serve roles in ventilation, filtration, sound absorption, and structural reinforcement, making them suitable for various engineering and architectural applications.Q: When should I choose a polished, metal perforated sheet for my project?

A: You should select these polished, metal perforated sheets when your project demands robust durability, efficient airflow, and added corrosion resistance. Their polished finish makes them particularly suitable for environments where aesthetics and hygiene are important, in addition to functionality.Q: Where can I source round hole perforated sheets in India?

A: As a trusted exporter, manufacturer, supplier, and trader in India, we offer these perforated sheets to clients nationwide and internationally. They are available in standard sizes for quick integration into your operations, with customization possible upon request.Q: What is the process for surface treatment on these sheets?

A: Each sheet undergoes a meticulous polishing process, resulting in a lustrous silver surface. This treatment removes impurities and enhances the metals resistance to corrosion and easy maintenance, ensuring the product remains in optimal condition during industrial use.Q: How are these perforated sheets typically used in industry?

A: Common industrial applications include use as safety guards, partitions, filtration elements, screening, and acoustic panels. Their uniform pattern ensures efficiency and versatility in a wide range of equipment and facility designs.Q: What are the main benefits of using these polished, round hole perforated sheets?

A: Key benefits include excellent structural strength, superior corrosion resistance, enhanced appearance due to the polished surface, and versatile functionality across various industrial applications. Their standardized sizing streamlines installation and integration into existing systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Round Hole Perforated Sheets Category

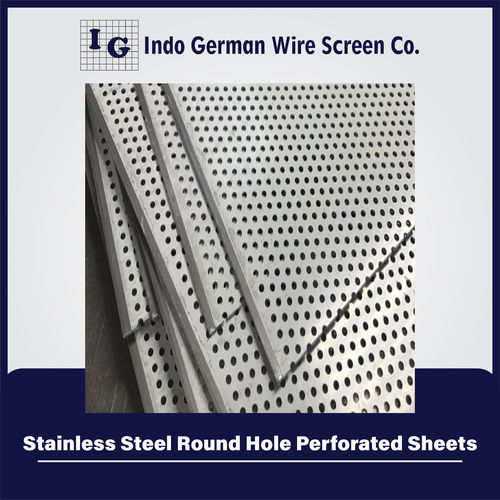

Stainless Steel Round Hole Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Other , Polished, Mill Finish

Type : Perforated Sheet

Material : Stainless Steel

Process : Punching / Stamping

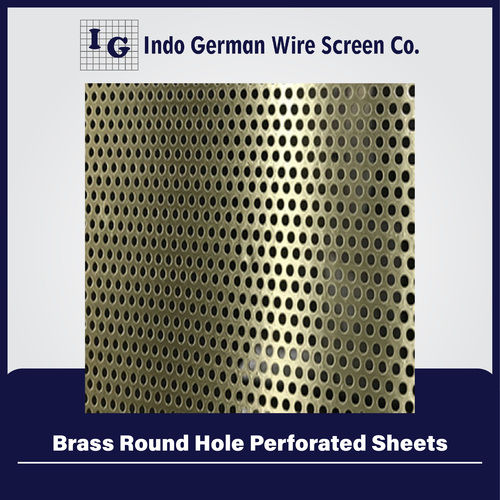

Brass Round Hole Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Polishing

Type : Perforated Sheets

Material : Other , Brass

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry