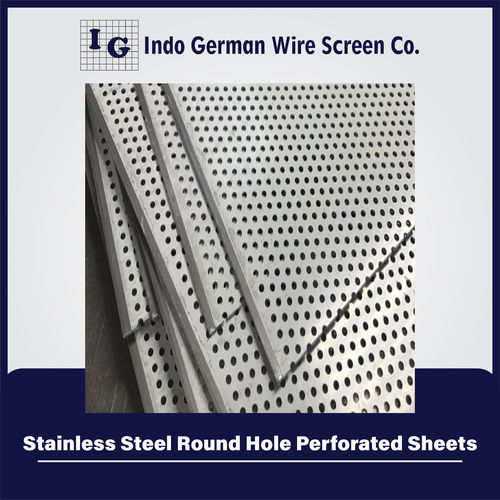

Stainless Steel Round Hole Perforated Sheets

Price 50 INR/ Unit

Stainless Steel Round Hole Perforated Sheets Specification

- Standard

- ASTM, JIS, DIN, BS

- Process

- Punching / Stamping

- Temper

- Hard, Soft, Half Hard

- Shape

- Rectangle, Sheet Form

- Surface Treatment

- Polished, Mill Finish

- Material

- Stainless Steel

- Type

- Perforated Sheet

- Technique

- Perforated

- Thickness

- 0.5 mm to 5 mm

- Application

- Industrial, Architectural, Filtration, Acoustic Panels, Screening, Food Processing, Ventilation

- Feature

- Corrosion Resistance, Durability, High Strength, Uniform Round Holes

- Color

- Silver

- Usage

- Decorative, Security Screens, Machinery Guards, Sieving, Drying, Vent Covers

- Grade

- 304, 316, 316L, 202

- Packaging

- Wooden Pallets, Bundles, Custom Packing

- Edge Type

- Plain, Slit, Sheared

- Tensile Strength

- As per Material Grade

- Sheet Size

- 1000 mm x 2000 mm, 1220 mm x 2440 mm, Custom Sizes Available

- Hole Size

- 1 mm to 20 mm

- Open Area Percentage

- 10% to 60%

- Width

- up to 1500 mm

- Hole Pattern

- Round

- Length

- up to 6000 mm

About Stainless Steel Round Hole Perforated Sheets

Stainless Steel has high tensile strength, temperature resistance, impact resistance, and excellent strength-to-weight ratio. Stainless steel also comprises variable quantities of carbon, silicon, manganese, and other elements such as nickel and molybdenum can be added to impart other advantageous properties such as enhanced formability and increased corrosion resistance. Stainless Steel has features like attractive appearance and high cleanability, low-maintenance, durable material and environmentally friendly (recyclable). Stainless Steel has these characteristics, in combination with usually low cost, greater sustainability, and superior aesthetic appearance, have led it becoming one of the most extensively used construction materials across a varied set of industries.

Stainless Steel Round Hole Perforated Sheets contain round hole patterns that can be staggered or straight lines. Staggered patterns put the holes out of alignment, while a straight line has holes arranged parallel and perpendicular to each other. There are three options for end margins, which include finished, unfinished, and blank. Finished margins are uniform and complete whereas unfinished are not solid at the edge of the sheet. We offer an exclusive range of Stainless Steel Round Hole Perforated Sheets at unmatched quality and market leading prices.

Versatile Applications

Stainless Steel Round Hole Perforated Sheets serve a broad range of industries, including industrial manufacturing, architectural design, and food processing. Their uniform holes and customizable open areas make them ideal for ventilation systems, acoustic panels, machinery guards, filtration units, and decorative elements.

Premium Material Quality

Crafted from high-grade stainless steel 304, 316, 316L, and 202, these perforated sheets are engineered to withstand demanding environments. Their corrosion-resistant properties and high tensile strength ensure longevity, while surface treatments such as polishing or mill finish provide exceptional aesthetics and protection.

Flexible Customization Options

Clients can choose from various hole diameters, sheet sizes, edge types, thicknesses, and surface treatments. Custom sizing and packing are available to suit specific project requirements. This flexibility enables the sheets to seamlessly integrate into various applications, providing practical and aesthetic benefits.

FAQs of Stainless Steel Round Hole Perforated Sheets:

Q: How are stainless steel round hole perforated sheets manufactured?

A: These sheets are produced using precision punching or stamping techniques that create evenly spaced round holes. High-quality stainless steel material is selected based on the desired grade, thickness, and surface finish to meet industry standards such as ASTM, JIS, DIN, and BS.Q: What is the benefit of selecting different open area percentages for perforated sheets?

A: Varying the open area percentage, from 10% to 60%, allows you to control factors such as air flow, light transmission, and filtration capacity. This customization is crucial for applications ranging from acoustic panels to sieving and ventilation covers.Q: When should I choose a particular stainless steel grade for my application?

A: Select the material grade304, 316, 316L, or 202based on corrosion resistance and strength requirements. For highly corrosive settings or food processing, 316 and 316L are ideal. For general decorative or structural needs, 304 and 202 provide cost-effective options.Q: Where can these perforated sheets be used effectively?

A: They are widely used in industrial machinery guards, architectural screening, filtration systems, acoustic panels, food processing units, and ventilation applications. Their adaptability makes them suitable for outdoor and indoor environments alike.Q: What surface treatments are available for stainless steel perforated sheets?

A: You can choose polished, mill finish, or custom surface treatments, depending on aesthetic and functional requirements. Each finish offers a unique appearance and can enhance corrosion resistance or ease of cleaning.Q: How do I determine the right sheet size and thickness for my project?

A: The choice depends on your intended use and structural requirements. Standard sizes like 1000 mm x 2000 mm and 1220 mm x 2440 mm are available, with custom sizes on request. Thickness options from 0.5 mm to 5 mm support various load-bearing and design needs.Q: What packaging options are provided to ensure safe delivery?

A: Sheets can be packed using wooden pallets, bundles, or tailored packaging solutions, ensuring they are well-protected during transport and handling, whether youre an exporter, manufacturer, supplier, or trader in India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Round Hole Perforated Sheets Category

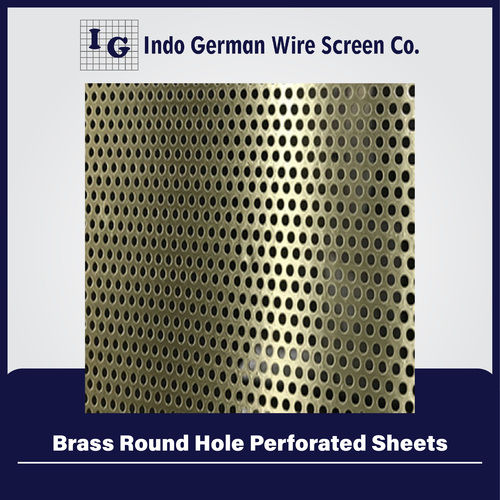

Brass Round Hole Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Polishing

Product Type : Brass Round Hole Perforated Sheets

Size : Standard

Type : Perforated Sheets

Round Hole Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Polishing

Product Type : Round Hole Perforated Sheets

Size : Standard

Type : Perforated Sheets

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry