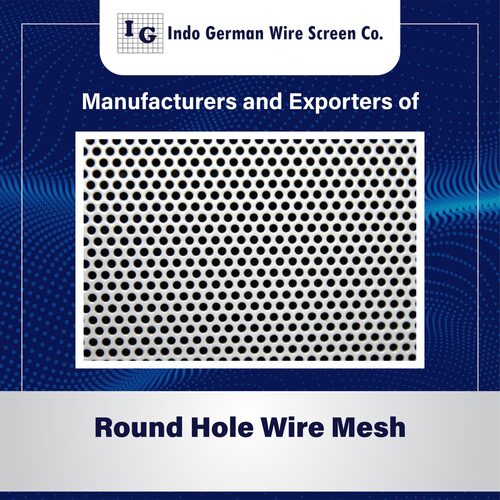

Round Hole Wire Mesh

Round Hole Wire Mesh Specification

- Surface Treatment

- Polished

- Hole Shape

- Square Hole

- Product Type

- Wire Mesh

- Mesh Type

- Iron Wire Mesh

- Material

- Steel

- Color

- Sliver

Round Hole Wire Mesh Trade Information

- Minimum Order Quantity

- 10 Square Meters

- Supply Ability

- 10 Square Meters Per Day

- Delivery Time

- 1 Week

About Round Hole Wire Mesh

Product Details:

| Material | Medium SS, SS304, SS316, Coarse SS, Fine SS |

| Mesh Size(per inch) | 10-50, 0-10, 50-100 |

| Mesh Size | 10-50 per inch, 0-10 per inch |

| Surface Finish Coating | Mill Finish Coating, Black Powder Coating |

| Weave Type | Twill, PSW |

| Type | Expanded Wire Mesh |

| Brand | Indo german Wire Screen |

We are one of the leading manufacturers, supplier, exporters and stockist of Round Hole Wire Mesh in Mumbai, India.

Applications of Round Hole Wire Mesh

- For Mining industry

- For construction industry

- For petrochemical industry

- For Cement industry

- For food processing industry

- Heavy duty scalping and sizing of rocks, aggregates, limestone and etc

- For Filtering and separating

- For Pharmaceuticals Industry

- For Chemical industries

- For Rubber industries

- For automobile industries

Almost all types of Alloys can be used in producing Crimped Wire Mesh Aluminium Wire Mesh, Brass Wire Mesh, Bronze Wire Mesh, Copper Wire Mesh, Galvanized Wire Mesh, Monel 400 Wire Mesh, Steel Wire Mesh, Stainless Steel Welded Wire Mesh, Stainless Steel Wire mesh, Hastelloy Wire mesh, Inconel Wire Mesh, Nichrome A Wire Mesh, Titanium Wire mesh, Tungsten Wire mesh, Mild Steel Wire Mesh, Iron Wire Mesh, Incoloy Wire Mesh and Nickel Wire Mesh

High-Quality Construction

Made with durable steel and finished with a polished surface, our wire mesh guarantees longevity and resistance to wear and corrosion. The square holes provide uniformity and enhanced performance, suitable for demanding environments.

Versatile Applications

This mesh type is widely utilized in industries such as construction, mining, food processing, and security. Its iron wire construction and square hole design allow it to perform effectively for filtration, screening, and protection needs.

FAQs of Round Hole Wire Mesh:

Q: How is the Round Hole Wire Mesh with a square hole manufactured?

A: The mesh is produced using high-grade steel wires woven or welded to create precise square holes. After forming, the surface undergoes polishing for a lustrous silver appearance, improving corrosion resistance and visual appeal.Q: What are the primary uses of polished iron wire mesh with square holes?

A: It is commonly used in filtration systems, protective fencing, screening materials, industrial sieving, and architectural designs due to its strength, durability, and uniform appearance.Q: When should I choose polished steel wire mesh over other types?

A: Opt for polished steel wire mesh when you need a product that combines corrosion resistance, aesthetic appeal, and strong structural integrity, especially in harsh or high-traffic environments.Q: Where is this wire mesh exported from in India?

A: The product is exported, manufactured, supplied, and traded by leading companies in India who ensure strict quality standards for international and domestic shipments.Q: What is the process involved in achieving the polished surface treatment?

A: After the mesh is formed, it undergoes mechanical or chemical polishing. This removes impurities and creates a smooth, reflective silver finish that enhances both the meshs longevity and visual appeal.Q: How does the square hole shape benefit the wire meshs applications?

A: Square holes provide consistent spacing and even load distribution, making the mesh suitable for uniform filtration and screening tasks. This shape also facilitates efficient visibility and airflow.Q: What are the advantages of using iron wire mesh crafted from steel?

A: Steel-based iron wire mesh offers superior tensile strength, durability, and resistance to environmental factors, ensuring extended service life and reliability in various industrial and architectural uses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh Category

Nylon Wire Mesh

Price 12 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Product Type : Wire Mesh

Mesh Type : Iron Wire Mesh

Material : Other

Surface Treatment : Painted

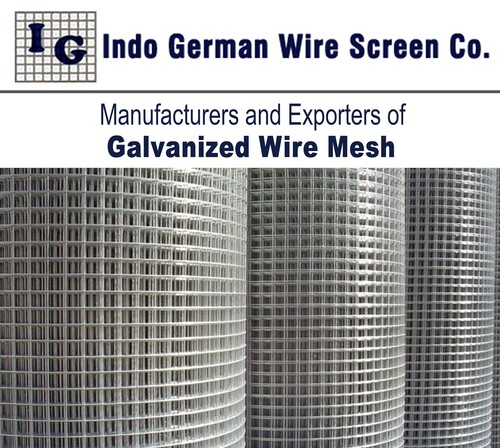

Galvanized Square Wire Mesh

Price 1000 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Product Type : Wire Mesh

Mesh Type : Iron Wire Mesh

Material : Galvanized Steel

Surface Treatment : Polished

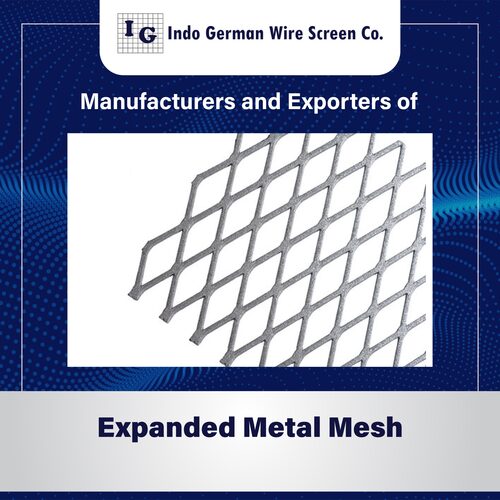

Expanded Metal Mesh

Price 30 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Product Type : Wire Mesh

Mesh Type : Aluminum Wire Mesh

Material : Aluminum

Surface Treatment : Polished

Twill Dutch Weave Wire Mesh

Price 130 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Product Type : Wire Mesh

Mesh Type : Steel Wire Mesh

Material : Steel

Surface Treatment : Painted

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry