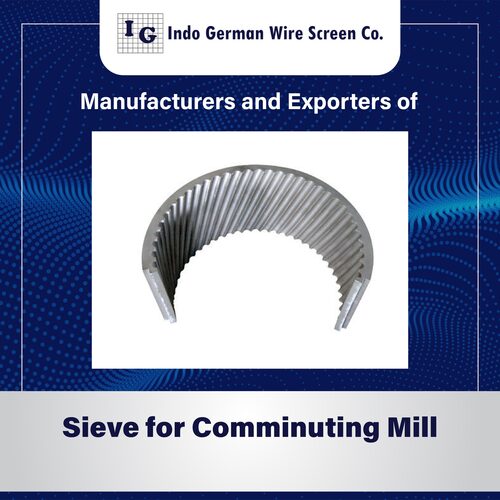

Sieve for Comminuting Mill

Sieve for Comminuting Mill Specification

- Usage

- industrial

- Material

- Stainless Steel

- Size

- 100 - 450 mm

- Condition

- New

- Product Type

- Sieve for Comminuting Mill

- Power Mode

- Manual

Sieve for Comminuting Mill Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 1 Week

About Sieve for Comminuting Mill

This sieve was meticulously designed to fulfill the strict specifications of contemporary manufacturing facilities. Our Sieve for Comminuting Mill offers repeatable and trustworthy outcomes whether you are working with powders, granules, or even delicate materials. Sieve is made to survive the rigors of regular usage in industrial environments since it is made of strong, corrosion-resistant components. Its durable design promotes longevity, which eventually lowers maintenance expenses. Our Sieve for Comminuting Mill features an expertly crafted mesh design that ensures effective sieving and uniform particle size distribution.

Product details

|

Hole Size |

250 microns to 20 mm |

|

Material |

Stainless Steel-316 and 316-L Quality |

|

Material Grade |

SS( 304 /304L /310/316/316L/317/317L/330/347/904/410/430/, ASTM E-674, ASTM E-454 |

|

Size |

100 - 450 mm |

Versatile Sizing for Diverse Industries

Available in sizes from 100 mm to 450 mm, our comminuting mill sieves address a wide spectrum of industrial granulation and size reduction needs. Whether for small batch processing or larger-scale operations, the right size is readily available to seamlessly fit your equipment and process requirements.

Premium Stainless Steel Construction

Constructed using robust stainless steel, these sieves offer excellent resistance to corrosion and wear, ensuring long-lasting performance in demanding environments. Their strength and precision help deliver consistent comminution results, making them an ideal choice for pharmaceutical, chemical, and food sector applications.

FAQs of Sieve for Comminuting Mill:

Q: How is the Sieve for Comminuting Mill used in industrial applications?

A: The sieve is inserted into a comminuting mill where it acts as a screening and size reduction medium. When materials are processed in the mill, they pass through the sieve, which controls final particle size and ensures uniformity in products such as powders or granules.Q: What materials are used in manufacturing these sieves?

A: These sieves are manufactured using stainless steel, which provides high strength, excellent durability, and corrosion resistance. This makes them well-suited for rigorous industrial applications and compliance with sanitary standards.Q: When should a sieve in a comminuting mill be replaced?

A: A sieve should be replaced whenever there are signs of wear, deformation, clogging, or if the mesh begins to affect the consistency of the output material. Regular inspections help ensure optimal performance and product quality.Q: Where are these stainless steel sieves commonly utilized?

A: These sieves are widely employed in industries such as pharmaceuticals, chemicals, and food processing, specifically where uniform granulation and reliable particle size control are critical for product quality.Q: What is the process for installing the sieve in a comminuting mill?

A: The sieve is manually fitted into the comminuting mills designated holder or chamber, ensuring a secure and stable placement. Detailed installation guidelines are provided to guarantee proper alignment and safe operation.Q: How does using a stainless steel sieve benefit industrial operations?

A: Stainless steel sieves offer exceptional longevity and easy maintenance, reducing downtime for replacements and ensuring hygienic processing. Their robustness contributes to consistent product quality and efficient operation in demanding production environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sieves for Multimills Category

Turbo Mill Sieve

Product Type : Turbo Mill Sieve

Material : Stainless Steel

Condition : New

Power Mode : Manual

Usage : industrial

Shape : Other, Square,Circular

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry