Turbo Mill Sieve

Turbo Mill Sieve Specification

- Usage

- industrial

- Material

- Stainless Steel

- Condition

- New

- Shape

- Square,Circular

- Product Type

- Turbo Mill Sieve

- Power Mode

- Manual

Turbo Mill Sieve Trade Information

- Supply Ability

- 10 Per Day

- Delivery Time

- 1 Week

About Turbo Mill Sieve

We are one of the best manufacturer and supplier of Turbo Mill Sieve that is specially designed for cylindrical shaped hammer mills for the sizing, milling, and de-lumping of raw materials. The size of this spare part is available in various sizes that can be customized according to milling machine in which it is going to be installed. It is provided with a galvanized coating that gives excellent protection from rust and corrosion. Buy from us Turbo Mill Sieve in bulk at a reasonable and low price range.

Product details

|

Hole Shape |

Square,Circular |

|

Hole Size |

250 microns to 20 mm |

|

Material |

Stainless Steel-316 and 316-L Quality |

|

Material Grade |

ASTM E-674,ASTM E-454,ISO-9044 |

Robust Stainless Steel Construction

Constructed from premium stainless steel, the Turbo Mill Sieve guarantees hygiene, corrosion resistance, and long-term durability, making it ideal for rigorous industrial environments. Both square and circular shapes allow integration into various production lines and offer flexibility for customized requirements.

Versatile Industrial Applications

This Turbo Mill Sieve is designed specifically for demanding sectors such as pharmaceuticals, food processing, and chemicals. Its manual power mode ensures control and safety, while the design facilitates efficient sieving and grinding of dry or wet materials, improving process productivity.

FAQs of Turbo Mill Sieve:

Q: How does the Turbo Mill Sieve function in industrial settings?

A: The Turbo Mill Sieve operates manually to separate or grade materials based on particle size, using centrifugal forces within its robust stainless steel chamber for efficient sieving in high-volume industrial applications.Q: What materials can be processed using this sieve?

A: This sieve is suitable for a wide range of materials, including powders, granules, and coarse particles commonly found in pharmaceutical, chemical, and food processing industries.Q: Where is the Turbo Mill Sieve manufactured and supplied from?

A: The Turbo Mill Sieve is manufactured, exported, supplied, and traded from India, ensuring high-quality standards and reliable after-sales support for global and domestic clients.Q: What is the process for installing and operating the sieve?

A: Installation involves securely assembling the stainless steel frame and components, followed by manual power operation as per the provided guidelines. It seamlessly integrates into existing industrial workflows.Q: When should industries choose manual power mode for their Turbo Mill Sieve?

A: Manual power mode is ideal when process control, maintenance simplicity, and operational safety are priorities, particularly in environments where electric automation is not feasible or necessary.Q: What are the benefits of choosing a square or circular shaped sieve?

A: Square and circular shapes provide versatility, allowing the Turbo Mill Sieve to fit spatial requirements and specific process needs, enhancing material throughput and operational flexibility.Q: How does the stainless steel construction benefit industrial users?

A: Stainless steel ensures resistance to corrosion, ease of cleaning, and compliance with industry sanitation standards, thereby extending equipment lifespan and safeguarding product integrity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sieves for Multimills Category

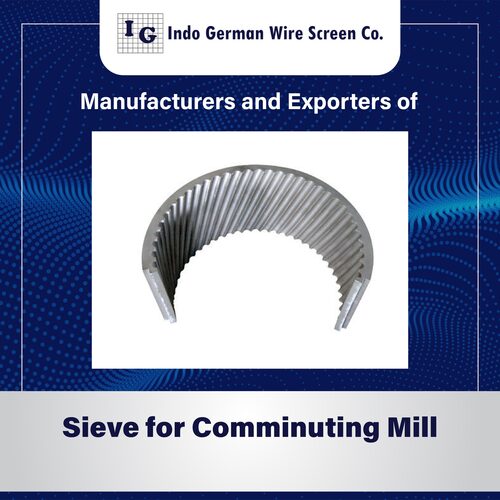

Sieve for Comminuting Mill

Minimum Order Quantity : 1 Piece

Product Type : Sieve for Comminuting Mill

Usage : industrial

Size : 100 450 mm

Power Mode : Manual

Condition : New

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry