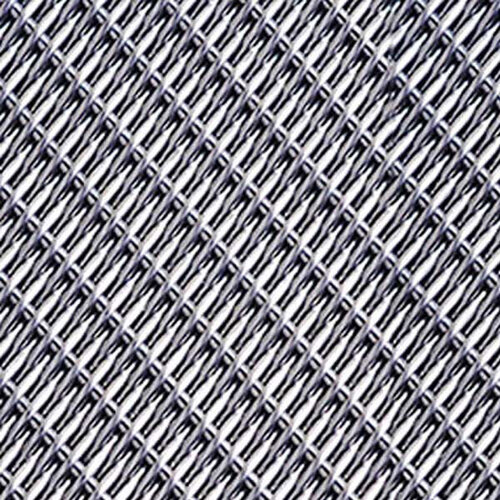

Stainless Steel Dutch Weave Wire Mesh

Price 50 INR/ Unit

Stainless Steel Dutch Weave Wire Mesh Specification

- Wire Gauge

- As per requirement

- Hole Shape

- Rectangular

- Length

- Available in custom lengths

- Aperture

- Typically between 5 to 80 microns

- Surface Treatment

- Coated

- Product Type

- Wire Mesh

- Mesh Type

- Dutch Weave

- Mesh Style

- Plain Mesh

- Material

- Stainless Steel

- Alloy

- SS304, SS316L

- Application

- Other

- Dimensions

- Rolls of 1 m or 1.2 m width

- Wire Diameter

- 0.025 mm to 0.90 mm

- Weight

- Depends on mesh size and roll length

- Color

- Gray

- Temperature Resistivity

- Up to 800°C

- Packing

- Plastic film and wooden box

- Weave Type

- Dutch Weave (Reverse Dutch or Plain Dutch options)

- Thickness

- As per specification

- Open Area

- Low, suitable for fine filtration

- Corrosion Resistance

- Excellent

- Standard

- ASTM, DIN

- Length per Roll

- 15 m, 30 m, or customized

Stainless Steel Dutch Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Stainless Steel Dutch Weave Wire Mesh

Stainless steel is an alloy of iron with chromium and is the most comprehensive material having indispensable properties. Stainless Steel has properties like easy formability, manufacturability, corrosion resistant, fire and heat resistance. Stainless Steel has high tensile strength, temperature resistance, impact resistance, and excellent strength-to-weight ratio.ThisStainless steel dutch weave wire meshis strong and stable, easy to clean and with a good flow rate suitable for high-pressure liquid/solid separation.We offer an exclusive range ofStainless steel Dutch Weave Wire Meshat unmatched quality and market leading prices.

Superior Filtration Performance

The Dutch Weave style, available in reverse or plain options, provides exceptional fine filtration due to its tightly woven structure and low open area. This mesh is ideal for applications requiring precise filtration, such as in chemical, pharmaceutical, and food processing sectors. The rectangular and other hole shapes combined with micron-level apertures ensure reliable separation of even the finest particulates.

Excellent Durability and Versatility

Crafted from high-grade stainless steel (SS304, SS316L), the wire mesh resists corrosion and tolerates high temperatures up to 800C. With its robust coated surface treatment, the mesh maintains its performance and longevity even in aggressive environments. Customizable dimensions and thickness allow adaptation to varied industrial requirements.

Certified Quality Standards

Each roll of Stainless Steel Dutch Weave Wire Mesh is manufactured in compliance with international standards such as ASTM and DIN. Strict quality checks ensure consistency in wire gauge, aperture size, and overall mesh integrity, making it a reliable choice for filtration, separation, and protection tasks.

FAQs of Stainless Steel Dutch Weave Wire Mesh:

Q: How is Stainless Steel Dutch Weave Wire Mesh manufactured for fine filtration applications?

A: This mesh is woven using a Dutch technique, either plain or reverse, which interlaces thicker warp wires with thinner weft wires. The design produces a dense weave and low open area, suitable for filtering fine particles between 5 and 80 microns.Q: What benefits does the high temperature resistivity of up to 800C offer users?

A: Its ability to withstand extreme temperatures ensures reliable performance in high-heat environments, such as chemical processing, making it suitable for filtration tasks where lesser materials would degrade.Q: When should I choose Reverse Dutch Weave over Plain Dutch Weave?

A: Reverse Dutch Weave is preferred when enhanced mechanical strength and finer filtration are required. Plain Dutch Weave is more suitable for moderate filtration tasks where a balanced flow rate and filtration are needed.Q: Where is this stainless steel mesh commonly used?

A: It is widely utilized in industries requiring precise particle retention, including chemical processing, pharmaceuticals, food and beverage production, water treatment plants, and laboratory filtration systems.Q: What surface treatments are applied and how do they improve the mesh?

A: The mesh receives a coated surface treatment that enhances its resistance to corrosion and physical wear, prolonging lifespan and maintaining filtration efficiency even when exposed to harsh chemicals or abrasives.Q: What options are available for customizing roll dimensions and wire gauge?

A: Customers can specify roll lengths (15 m, 30 m, or customized), widths (1 m, 1.2 m), wire diameter (0.025 mm to 0.90 mm), and gauge to suit unique filtration or installation requirements.Q: How does compliant packing and adherence to standards benefit product delivery?

A: Packaging in plastic film and wooden boxes protects the mesh during transit, while compliance with ASTM and DIN standards guarantees product quality and performance consistency for international clients.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dutch Weave Wire Mesh Category

Steel Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Mesh Style : Plain Mesh

Color : Gray

Application : Other

Stainless Steel Welded Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Mesh Style : Plain Mesh

Color : Gray

Application : Other

Hastelloy Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Mesh Style : Other , Dutch Weave Wire Mesh

Color : Gray

Application : Other

Nichrome A Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Mesh Style : Other , Dutch Weave Wire Mesh

Color : Gray

Application : Other

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry