Stainless Steel Welded Five Shed Twill Weave Wire Mesh

Price 50 INR/ Unit

Stainless Steel Welded Five Shed Twill Weave Wire Mesh Specification

- Hole Shape

- Square / Rectangular

- Length

- 15-50 Meter Rolls (custom length available)

- Aperture

- 0.05 mm to 2 mm (customizable)

- Wire Gauge

- Available in 10 to 30 SWG

- Surface Treatment

- Coated

- Product Type

- Wire Mesh

- Mesh Type

- Steel Wire Mesh

- Mesh Style

- Five Shed Twill Weave

- Material

- Stainless Steel

- Alloy

- SS304, SS316, and optionally SS316L

- Application

- Other

- Dimensions

- Customizable, standard width up to 2 meters

- Wire Diameter

- 0.18 mm 2.5 mm

- Weight

- Varies by specification, approx. 1.5 to 8 kg/m

- Color

- Silver

Stainless Steel Welded Five Shed Twill Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Stainless Steel Welded Five Shed Twill Weave Wire Mesh

Stainless Steel Welded Five Shed Twill Weave Wire Meshalso called asFive-heddle weave wire clothconsists of a rectangular aperture in which each warp wire passes over four wires and under one to provide a very smooth surface on one side which helps in efficient removal of filter cake.Stainless Steel has these characteristics, in combination with usually low cost, greater sustainability, and superior aesthetic appearance, have led it becoming one of the most extensively used construction materials across a varied set of industries.TheStainless Steel Welded Five Shed Twill weave wire meshcloth is also exceptionally strong with good dewatering qualities and high flow rates.We offer an exclusive range ofStainless Steel Welded Five Shed Twill Weave Wire Meshat unmatched quality and market leading prices.

High Precision and Durability

With the Five Shed Twill Weave pattern, this stainless steel wire mesh is built to deliver superior strength and uniformity. Its high tensile strength and corrosion resistance make it reliable for continuous industrial processes and architectural uses. The mesh offers customizable specifications to suit a wide range of professional requirements.

Versatile Applications

This welded wire mesh is used in filtration, sieving, screening, reinforcement, and protective barriers across various industries. Its temperature resistance up to 800C extends its usability in harsh environments, while the ability to custom-tailor dimensions and openings ensures suitability for specialized tasks.

FAQs of Stainless Steel Welded Five Shed Twill Weave Wire Mesh:

Q: How is the Stainless Steel Welded Five Shed Twill Weave Wire Mesh manufactured?

A: The mesh is produced by weaving stainless steel wires in a Five Shed Twill pattern and welding or finishing the edges for enhanced strength. Advanced surface treatments and quality alloys (SS304, SS316, SS316L) ensure uniformity and corrosion resistance.Q: What benefits does the Five Shed Twill Weave offer for industrial filtration?

A: This weave provides a uniform mesh structure, resulting in high-precision filtration and reliable performance under tough conditions. Its design supports consistent particle retention and prevents mesh deformation during use.Q: When is it suitable to use this mesh in architectural projects?

A: The meshs high strength, modern silver appearance, and customizable dimensions make it ideal for architectural reinforcement, protective cladding, and aesthetic screening in building facades and interiors.Q: Where can the mesh be installed for effective protection and reinforcement?

A: It is commonly deployed as barriers, reinforcement panels, and protective screens in industrial plants, construction sites, and architectural applications, wherever durability and precision are essential.Q: What packaging process ensures safe delivery of the wire mesh?

A: The mesh is packed with waterproof paper, followed by plastic film wrapping, and optionally placed in wooden cases to protect against moisture and physical damage during transit.Q: How do I select the right aperture and wire gauge for my filtration needs?

A: Aperture sizes (0.05 mm to 2 mm) and wire gauges (1030 SWG) can be customized according to the specific filtration or screening requirements. Consulting with the supplier helps match mesh specifications to target applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Five Shed Twill Weave Wire Mesh Category

Tungsten Five Shed Twill Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other

Material : Metal Alloys

Product Type : Wire Mesh

Color : Silver

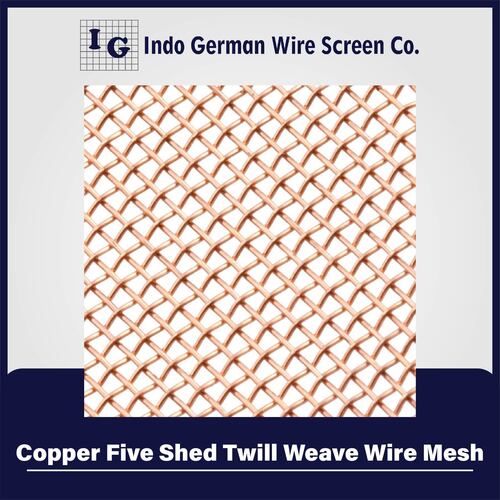

Copper Five Shed Twill Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other

Material : Steel

Product Type : Wire Mesh

Color : Copper

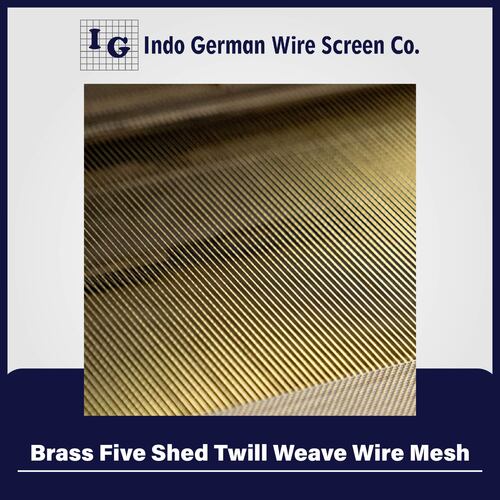

Brass Five Shed Twill Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other

Material : Other, Brass

Product Type : Wire Mesh

Color : Golden

Mild Steel Five Shed Twill Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other

Material : Other

Product Type : Wire Mesh

Color : Silver

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry