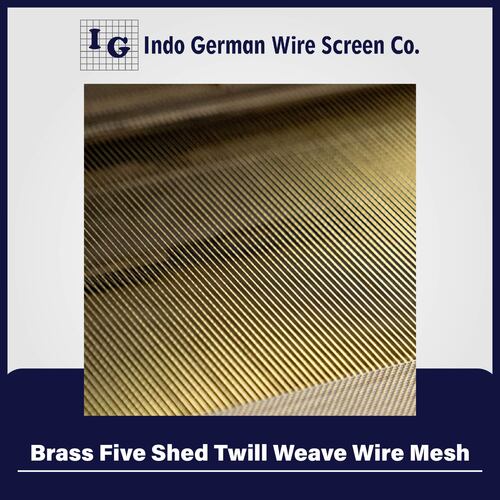

Brass Five Shed Twill Weave Wire Mesh

Price 50 INR/ Unit

Brass Five Shed Twill Weave Wire Mesh Specification

- Length

- 30 Meter Roll

- Hole Shape

- Square

- Wire Gauge

- 24 Gauge

- Surface Treatment

- Coated

- Aperture

- 0.3 mm

- Product Type

- Wire Mesh

- Mesh Type

- Five Shed Twill Weave

- Mesh Style

- Plain Mesh

- Material

- Brass

- Alloy

- Copper-Zinc Brass

- Application

- Other

- Dimensions

- 1 Meter x 30 Meter

- Wire Diameter

- 0.28 mm

- Weight

- Approx. 2.5 kg per roll

- Color

- Golden

- Finish

- Smooth

- Weave Type

- Five Shed Twill Weave

- Packing

- Waterproof Paper, Wooden Case

- Tensile Strength

- Good

- Shelf Life

- Long

- Corrosion Resistance

- Excellent

- Edge Type

- Plain Cut Edge

- Usage Temperature

- Up to 180°C

- Open Area

- 38%

Brass Five Shed Twill Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Brass Five Shed Twill Weave Wire Mesh

Brass is an alloy of copper and zinc and has improved resistance to abrasion and corrosion. Compared to copper, Brass has low electrical conductivity and is frequently used in sieving diversified pellets, powder, porcelain clay and glass, chinaware printing, filtering liquid and gas. The chemical composition of brass is 60-70% copper plus 30-40% zinc.TheBrass Five Shed Twill weave wire meshcloth is also exceptionally strong with good dewatering qualities and high flow rates.Brass Five Shed Twill Weave Wire Mesh could be Woven and Welded. We offer an exclusive range ofBrass Five Shed Twill Weave Wire Meshat unmatched quality and market leading prices.

Superior Five Shed Twill Weave Design

Engineered with a five shed twill weave, this brass wire mesh provides enhanced structural strength and a smooth surface, making it suitable for both heavy-duty filtration and aesthetic architectural applications. The mesh is delivered with plain cut edges to maintain precision and reduce fraying.

Excellent Corrosion Resistance & Longevity

Made from copper-zinc brass alloy, the mesh boasts outstanding resistance to corrosion, even in harsh environments. Its long shelf life and durable construction ensure reliable performance, minimizing the need for frequent replacements in demanding industrial settings.

High Temperature and Tensile Strength

This wire mesh withstands usage temperatures up to 180C and maintains good tensile strength, making it a dependable choice for operations involving heat and frequent mechanical stress. Its surface treatment increases resistance further, keeping it robust and reliable.

FAQs of Brass Five Shed Twill Weave Wire Mesh:

Q: How is the Brass Five Shed Twill Weave Wire Mesh manufactured?

A: The mesh is produced using brass wires arranged in a five shed twill weave pattern, resulting in a robust structure with a smooth finish and enhanced durability. Edges are plain cut to ensure precision and minimal fraying.Q: What applications is this wire mesh suitable for?

A: This mesh is commonly used in filtration, separation, screening, and architecturally decorative projects due to its fine aperture, smooth surface, and corrosion resistance. It is ideal for use in environments that require robust materials with good tensile strength.Q: Where can the Brass Five Shed Twill Weave Wire Mesh be installed?

A: It is suitable for installation in industrial facilities, chemical plants, architectural structures, and other areas where filtration, protection, or decorative elements are needed, especially where exposure to moisture or corrosive agents is expected.Q: What are the benefits of using a five shed twill weave design?

A: The five shed twill weave enhances the meshs strength and flexibility, making it suitable for applications that demand durability and fine filtration. This weaving style also contributes to the meshs smooth and visually appealing surface.Q: How does the mesh resist corrosion and environmental damage?

A: Manufactured from copper-zinc brass and treated with a protective coating, the mesh offers excellent resistance against corrosion, providing reliable performance in environments prone to moisture, chemicals, or temperature fluctuations.Q: When should this wire mesh be replaced or maintained?

A: Thanks to its high-quality brass alloy and protective coating, the mesh has a long shelf life and requires minimal maintenance. Replacement is generally needed only in cases of significant physical damage or prolonged exposure to extreme conditions.Q: What kind of packing is used for safe delivery of the mesh?

A: The mesh is packed in waterproof paper and a wooden case to protect it from moisture and physical damage during storage and transportation, ensuring it arrives in optimal condition for immediate use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Five Shed Twill Weave Wire Mesh Category

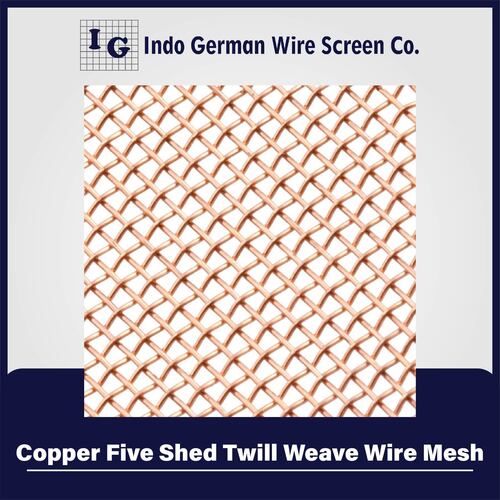

Copper Five Shed Twill Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other

Mesh Type : Other , Five Shed Twill Weave

Product Type : Wire Mesh

Material : Steel

Tungsten Five Shed Twill Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other

Mesh Type : Other , Woven

Product Type : Wire Mesh

Material : Metal Alloys

Aluminium Five Shed Twill Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other

Mesh Type : Other , Twill Weave

Product Type : Wire Mesh

Material : Aluminum

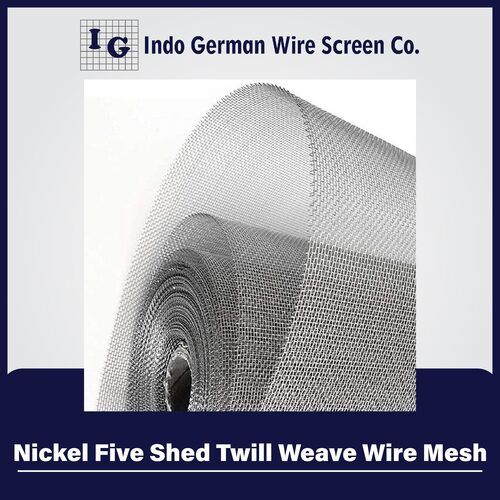

Nickel Five Shed Twill Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other

Mesh Type : Other , Nickel Five Shed Twill Weave Wire Mesh

Product Type : Wire Mesh

Material : Other, Nickel

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry