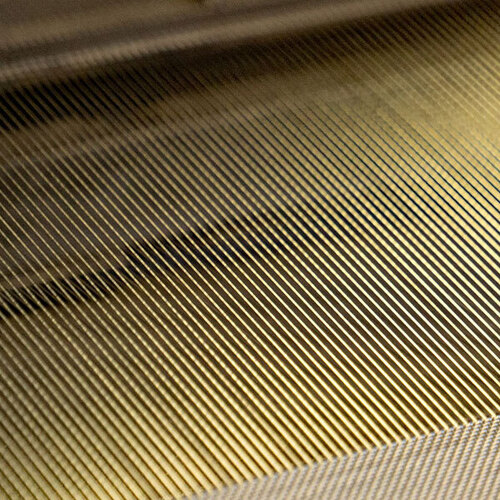

Steel Five Shed Twill Weave Wire Mesh

Price 50 INR/ Unit

Steel Five Shed Twill Weave Wire Mesh Specification

- Length

- Custom Lengths Available

- Aperture

- Precise, as per specifications

- Hole Shape

- Square

- Wire Gauge

- Standard or Custom (as per requirement)

- Surface Treatment

- Coated

- Product Type

- Wire Mesh

- Mesh Type

- Steel Wire Mesh

- Mesh Style

- Plain Mesh

- Material

- Steel

- Alloy

- Steel Alloy

- Application

- Filtration, Separation, Sieving, Industrial Uses

- Dimensions

- Custom Sizes Available

- Wire Diameter

- Fine to Medium (as specified)

- Weight

- Variable, Based on Specification

- Color

- Silver Grey

- Temperature Resistance

- High

- Manufacturing Method

- Woven

- Packing

- Rolls, Sheets or as required

- Usage Environment

- Indoor & Outdoor

- Opening Size

- As per Design Specification

- Feature

- High Strength, Durable, Corrosion Resistant

- Edge Type

- Cut or Finished Edge Available

- Weave Type

- Five Shed Twill Weave

Steel Five Shed Twill Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Steel Five Shed Twill Weave Wire Mesh

InSteel Five Shed Twill Weave Wire Meshalso called asFive-heddle weave wire clothconsists of a rectangular aperture in which each warp wire passes over four wires and under one to provide a very smooth surface on one side which helps in efficient removal of filter cake.TheSteel Five Shed Twill weave wire meshcloth is also exceptionally strong with good dewatering qualities and high flow rates.Steel Five Shed Twill Weave Wire Mesh can be Woven and Welded. We offer an exclusive range ofSteel Five Shed Twill Weave Wire Meshat unmatched quality and market leading prices.

Superior Weaving for Enhanced Performance

The five-shed twill weave structure imparts greater strength and dimensional stability to the steel wire mesh compared to standard weaves. This method results in a more robust mesh that withstands higher mechanical stress, making it perfect for rigorous industrial tasks such as filtration and separation.

Flexible Customization Options

Our steel wire mesh can be tailored according to your project requirements. Choose your preferred wire gauge, aperture, dimensions, and edge type to ensure the mesh fits precisely within its intended application. Both standard and custom specifications are available, supporting a wide spectrum of uses.

Reliable in Extreme Conditions

Engineered for high temperature resistance and long-term durability, this mesh thrives in both indoor and outdoor environments. Its corrosion-resistant surface treatment ensures a prolonged service life, even under harsh industrial or environmental conditions, offering dependability where it matters most.

FAQs of Steel Five Shed Twill Weave Wire Mesh:

Q: How is the Steel Five Shed Twill Weave Wire Mesh manufactured?

A: This mesh is woven using a specialized five-shed twill weave process, which increases its mechanical strength and provides precise openings. The manufacturing method allows for custom wire diameters, opening sizes, and finishes, ensuring it meets individual application needs.Q: What benefits does the five-shed twill weave offer over other weaves?

A: The five-shed twill weave enhances mesh flexibility while maintaining high tensile strength, making it more resistant to mechanical stress and deformation. This structure is ideal for demanding industrial operations that require reliable filtration and separation under pressure.Q: When should I choose coated or finished-edge options for my mesh?

A: Coated meshes are recommended for environments with high moisture or corrosive exposure, as they extend the lifespan of the wire mesh. Finished edges provide additional safety and are preferred for applications where mesh will be handled frequently or where a clean boundary is necessary.Q: Where can this type of wire mesh be used effectively?

A: It is suitable for industrial environments requiring dependable filtration, sieving, and separation. Applications include chemical processing, food production, mining, and architectural installations, both indoors and outdoors.Q: What customization options are available?

A: You can specify wire diameter, mesh opening size, length, width, edge type, surface treatment, and aperture shape. These customizations ensure optimal performance tailored to specific processes and project requirements.Q: How does the mesh perform in high temperature or corrosive settings?

A: Thanks to its high-quality steel construction and optional coatings, the mesh maintains structural integrity and resists corrosion even at elevated temperatures, making it suitable for both indoor and outdoor industrial use.Q: What is the process for ordering this mesh with special specifications?

A: Provide detailed requirements such as dimensions, aperture size, wire gauge, edge type, and intended application. The manufacturer or supplier will then tailor the production and deliver the mesh in rolls, sheets, or as otherwise required.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Five Shed Twill Weave Wire Mesh Category

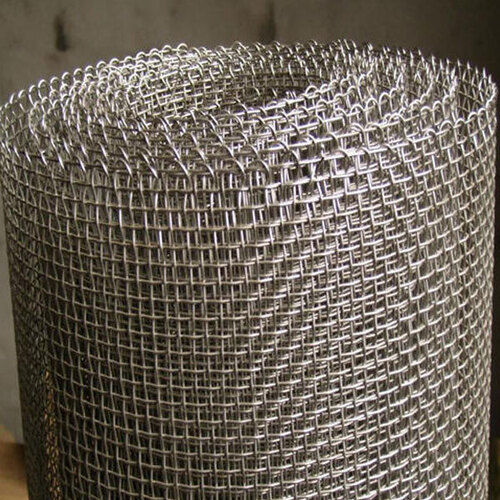

Stainless Steel Welded Five Shed Twill Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Color : Silver

Application : Other

Surface Treatment : Coated

Bronze Five Shed Twill Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Color : Bronze

Application : Other

Surface Treatment : Coated

Nichrome A Five Shed Twill Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Color : Silver

Application : Other

Surface Treatment : Coated, Powder Coating

Monel 400 Five Shed Twill Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Color : Silver

Application : Other

Surface Treatment : Coated

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry