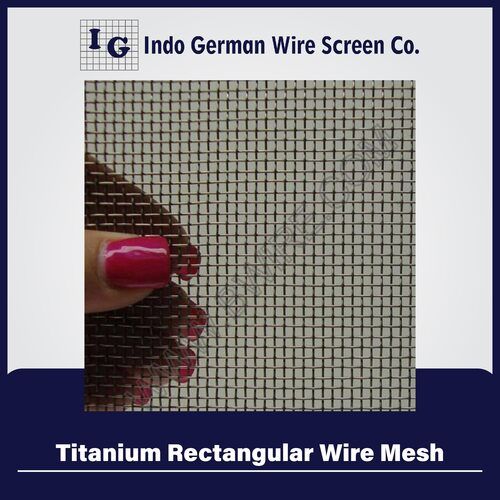

Titanium Rectangular Wire Mesh

Price 50 INR/ Unit

Titanium Rectangular Wire Mesh Specification

- Surface Treatment

- Coated

- Product Type

- Wire Mesh

- Mesh Type

- Titanium Wire Mesh

- Mesh Style

- Plain Mesh

- Color

- Silver

Titanium Rectangular Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Titanium Rectangular Wire Mesh

Titanium is known for its high durability, light weight, high strength, and corrosion-resistant properties. Titanium metal is resistant to saltwater, metallic salts, hydroxides, chromic acids, chlorides, nitric acids, organic acids, and dilute alkalis. Titanium is available in black colour, with diverse weaving patterns of plain and twill weave.Titanium Rectangular Wire cloth plain weaveis the most frequently used weave in which each warp wire crosses interchangeably above and below each weft wire. Warp wires and weft wires usually have the same diameter.We offer an exclusive range ofTitanium Rectangular Wire Meshat unmatched quality and market leading prices.

Superior Quality and Performance

Our titanium rectangular wire mesh stands out due to its robust construction and silver coated finish, offering impressive resistance to corrosion and wear. This ensures reliable performance even in harsh environments, making it an excellent choice for industries requiring stable and long-lasting filtration or protection solutions.

Versatile Applications

Thanks to its plain mesh style and durable surface treatment, this titanium mesh serves widely in sectors like chemical processing, aerospace, pharmaceuticals, and marine engineering. Its adaptability in filtration, sieving, and separation tasks underscores its value across multiple industrial domains.

FAQs of Titanium Rectangular Wire Mesh:

Q: How is the titanium rectangular wire mesh manufactured?

A: The mesh is manufactured using high-grade titanium wire, woven into a rectangular pattern with a plain mesh style. After weaving, it undergoes a coated surface treatment to enhance its corrosion resistance and longevity.Q: What are the primary uses of titanium rectangular wire mesh?

A: It is primarily utilized for filtration, screening, separation, and protective barriers in industries such as chemical processing, aerospace, pharmaceuticals, and marine applications.Q: When should I choose titanium wire mesh over other materials?

A: Titanium wire mesh is ideal when exceptional corrosion resistance, lightweight strength, and biocompatibility are required, particularly in aggressive or high-temperature environments.Q: Where can this mesh be installed or applied?

A: The mesh can be installed in filtration units, sieving machinery, heat exchangers, ventilation panels, and protective enclosures in both indoor and outdoor industrial settings.Q: What is the process behind the coating of the mesh?

A: After the titanium wires are woven into the desired rectangular pattern, a protective coating is applied to the surface. This process enhances resistance to oxidation, chemicals, and mechanical wear.Q: What benefits does the coated titanium mesh offer compared to uncoated options?

A: The coating significantly improves the meshs durability, extends its service life, and provides superior resistance to environmental and chemical damage, making it suitable for demanding applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rectangular Wire Mesh Category

Nickel Rectangular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Color : Silver

Surface Treatment : Coated

Mesh Type : Other

Iron Rectangular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Color : Silver

Surface Treatment : Coated

Mesh Type : Iron Wire Mesh

Brass Rectangular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Color : Golden

Surface Treatment : Coated

Mesh Type : Other , Brass Wire Mesh

Tungsten Rectangular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Color : Silver

Surface Treatment : Coated

Mesh Type : Other , Tungsten Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry