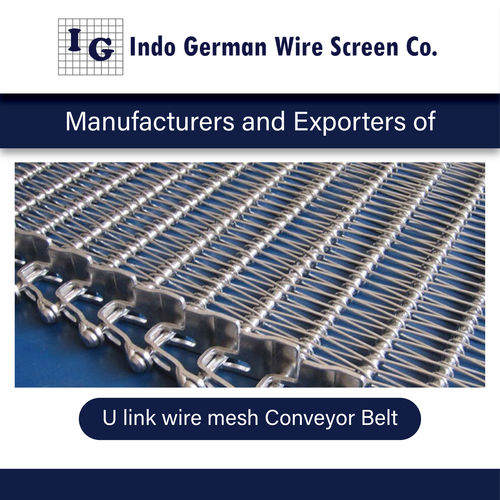

U Link Wire Mesh Conveyor Belt

Price 1000 INR/ Foot

U Link Wire Mesh Conveyor Belt Specification

- Thickness

- 2 mm 10 mm (customizable)

- Surface Finish

- Galvanized/Polished

- Power Source

- Mechanically driven

- Belt Type

- U Link wire mesh

- Features

- High flexibility, smooth performance, long operating life, easy maintenance

- Material

- High-grade stainless steel

- Type

- Wire Mesh Conveyor Belt

- Structure

- U Link interlocking mesh construction

- Belt Conveyor

- Yes

- Product Type

- Heat resistance

- Color

- Steel

- Resistant Feature

- Heat resistance, corrosion resistant

- Load Capacity

- Heavy-duty, customizable as per requirement

- Speed

- Customizable as per application

- Usage & Applications

- Food processing, bakery, heat treatment, drying, cooling, and packaging industries

- Compliance

- Meets industrial food safety and material handling standards

- Mesh Opening Size

- As per requirement (customizable)

- Suitable Drive Options

- Compatible with sprocket or drum drive systems

- Operating Temperature Range

- Up to 1150°C

- Tensile Strength

- High tensile strength for heavy load handling

- Connection Method

- U shaped stainless steel links

- Edge Type

- Welded or knuckled edges for enhanced safety

- Belt Width

- Available from 300 mm up to 3000 mm

U Link Wire Mesh Conveyor Belt Trade Information

- Minimum Order Quantity

- 50 Feet, ,

- FOB Port

- mumbai

- Payment Terms

- Letter of Credit (L/C), Cash Advance (CA), Cash in Advance (CID), Cheque

- Delivery Time

- 7 Days

- Sample Policy

- If order is confirmed we will reimburse the sample cost

About U Link Wire Mesh Conveyor Belt

We are one of the renowned and reliable manufacturers, supplier, stockist and exporter of U link Conveyor Belt in Mumbai, India and are available in best quality Stainless Steel and Carbon Steel wire mesh Stainless Steel U link wire mesh conveyor belt and Carbon Steel U link wire mesh conveyor belt.Customizable Construction for Diverse Applications

Benefit from a conveyor belt tailored to meet specialized requirements. The U Link Wire Mesh Conveyor Belt offers customizable mesh opening sizes, belt widths, and thicknesses, accommodating different load capacities and operational speeds. Its design ensures suitability across industries like food processing, heat treatment, and packaging, making it an indispensable asset for manufacturers seeking operational flexibility.

Robust Performance Under Extreme Conditions

Engineered for high-temperature and corrosive environments, this belt provides outstanding durability with its stainless steel construction and galvanized or polished surface. It reliably handles temperatures up to 1150C and resists corrosion, ensuring long operating life even in aggressive processing settings for bakery and industrial applications.

Safety, Efficiency, and Regulatory Compliance

Safety is integral to the U Link Wire Mesh Conveyor Belt, featuring welded or knuckled edge options to enhance operator protection. Its smooth, flexible operation and compliance with industrial food safety and material handling standards enable seamless, hassle-free processes, reducing maintenance downtime and upholding stringent hygiene requirements.

FAQs of U Link Wire Mesh Conveyor Belt:

Q: How is the U Link Wire Mesh Conveyor Belt installed in a processing line?

A: installation involves securing the U shaped stainless steel link mesh onto a compatible conveyor frame, ensuring proper alignment with sprocket or drum drive systems. Custom sizing and edge type selection guarantee seamless integration regardless of the application, whether in food processing or heat treatment.Q: What benefits do welded or knuckled edges offer for safety and performance?

A: Welded or knuckled edges minimize the risk of snagging and accidental contact, providing enhanced safety for operators. They also contribute to belt stability, reducing wear at the edges and prolonging operational lifespan, which is crucial during high-load handling.Q: When should I opt for customized mesh opening size or belt width?

A: Custom mesh opening size and belt width are ideal when specific processing requirements demand precise material flow, product size, or throughput rates. Industries such as bakery, cooling, and packaging often require tailored conveyor solutions for optimal efficiency and product handling.Q: Where can this conveyor belt be utilized effectively?

A: This wire mesh conveyor belt is most effective in environments like food processing plants, bakeries, heat treatment facilities, drying and cooling stations, and packaging linesanywhere robust material handling under demanding conditions is required.Q: What processes does this belt support in industrial settings?

A: It is designed for critical processes such as conveying, drying, cooling, heating, and packaging of products. Its high flexibility and smooth performance allow for easy adaptation to diverse operational needs within the food and material handling sectors.Q: How does the belts heat resistance and load capacity benefit my operation?

A: The belts capability to withstand temperatures up to 1150C and handle heavy-duty loads ensures reliable, uninterrupted performanceminimizing downtime and maximizing throughput in continuous industrial processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Conveyor Belts Category

Truss Edge Wire Mesh Conveyor Belt

Price 1000 INR / Foot

Minimum Order Quantity : 50 Feet, ,

Structure : Other, Truss Edge

Type : Other, Wire Mesh Conveyor Belt

Material : HighGrade Stainless Steel

Belt Conveyor : Other, Yes

Metal Conveyor Belts

Minimum Order Quantity : 100 Square Foots

Structure : Belt

Type : Belt Conveyor

Material : Mild Steel

Belt Conveyor : Other, Yes

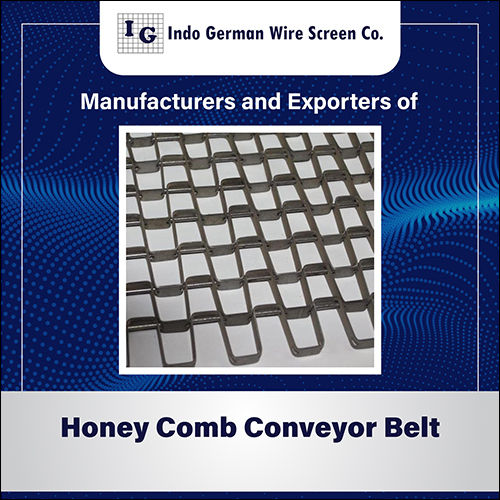

Honey Comb Conveyor Belt

Price 1000 INR / Foot

Minimum Order Quantity : 10 Feet, ,

Structure : Other, Stainless Steel Mesh Belt

Type : Other, Honey Comb Conveyor Belt

Material : Stainless Steel (AISI 304/316 optional)

Belt Conveyor : Other, Yes

Endless Flat Belts

Price 2000 INR / Meter

Minimum Order Quantity : 1 Meter

Structure : Belt

Type : Other, Endless Flat Belt

Material : Iron

Belt Conveyor : Other, Compatible

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry